ERP Software for Ethanol Manufacturing Industry

Boost operational efficiency and accuracy in ethanol manufacturing with our specialized Ethanol ERP Software

What is ERP Software for Ethanol Manufacturing Industry?

ERP Software for ethanol manufacturing industry is the compressive solution to seamlessly integrate and simplify core business processes such as manufacturing, production, inventory management, order processing, customer relationship management, human resources and financials. This advanced technology is designed to manage the ethanol production process seamlessly. Ethanol ERP helps to increase operational efficiency, provides real-time insights, accurately generates reports and seamlessly maintains supply chain integrity.

ERP software for biofuel industry offers tools and functionalities that help in compliance management, quality control and batch tracking. The ethanol industry has to abide by all the regulations strictly, ERP tracks the updates and ensures that the business follows them. All the data is centralized in the system which helps the manufacturers to make data-driven decisions, lower costs and improve the overall business efficiency

Overview of the Ethanol Manufacturing Industry

Ethanol manufacturing industry is a major player in the production of ethanol, which is one of the types of biofuel. This fuel is a sustainable option to the traditional fossil fuel. The industry utilises biomass sources such as corn and sugarcane starch, followed by the distillation process to produce ethanol. Utilising ethanol results in a more greener environment. Plus, it helps in controlling the emission of harmful substances in the environment.

The production process of the ethanol industry comprises stages such as selecting feedstocks, harvesting, processing, and incorporating advanced technologies. The global emphasis on sustainable energy is increasing the demand for the production of ethanol. Advancements in technology and consistent research will help in the growth of this industry.

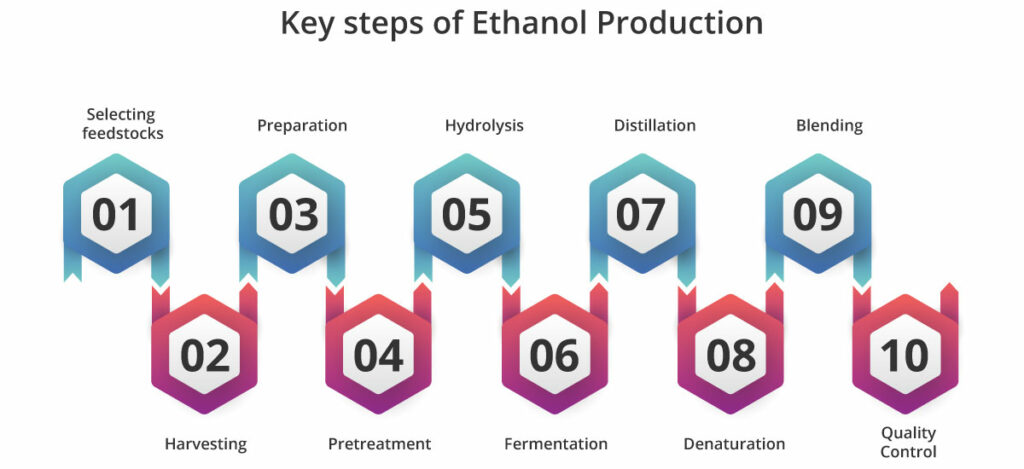

Key Steps of Ethanol Production

Ethanol production involves several steps which are listed below:

1. Selecting feedstocks: Selecting raw materials such as corn, cellulosic biomass or sugarcane for the ethanol manufacturing process.

2. Harvesting: In this stage, the selected feedstock is harvested at the optimal stage to increase sugar or starch content.

3. Preparation: This stage involves grinding or shredding. First, the feedstock is cleaned and prepared for processing.

4. Pretreatment: The feedstock is treated to break the complex structures paving the way for fermentation.

5. Hydrolysis: Through the process of enzymatic or chemical hydrolysis convert complex sugars into simple sugars.

6. Fermentation: The sugars are converted to ethanol and carbon dioxide by adding yeast or bacteria to the sugar-rich solution.

7. Distillation: By using distillation, concentrating and purification of the alcohol separate ethanol from the fermentation mixture.

8. Denaturation: As required and following all the regulations, add denaturation which makes it unsuitable for consumption.

9. Blending: Ethanol can be blended with gasoline or other natural fuels which helps in the creation of a fuel mixture, such as E10 or E85.

10. Quality Control: This is a crucial step where the product is tested thoroughly to check if it meets all the regulatory and industrial standards.

Global Ethanol Production

Historically, the use of ethanol goes back to 1978 when Brazil successfully ran a car completely using ethanol as fuel. At that time, research and development was still going on for this fuel. However, due to the rising environmental concerns, worldwide companies are switching to sustainable energy. One of these biofuels is ethanol.

According to Precedence Research, in 2023, the worldwide ethanol market exceeded a value of USD 103.62 billion, and projections indicate a potential growth to approximately USD 162.12 billion by the year 2032.

The US is the highest producer of ethanol followed by Brazil. The US produces ethanol with corn and Brazil with sugarcane. Together they produce about 82% of the ethanol globally.

Challenges Faced by the Ethanol Manufacturing Industry

Availability of Feedstock

This industry is highly reliant on stocks like corn and sugarcane. Due to fluctuations in the agricultural sector such as availability of stocks and pricing, the ethanol industry will be impacted.

Strict Compliance Management

In the ethanol industry, policies evolve due to the demand arising from environmental concerns. The regulations are stricter and the industry must meet the emission standards.

Fluctuating Market Conditions

The factors influencing the ethanol industry are global demand, pricing, and government policies on biofuels. Volatility in the market will impact the industry’s profitability and long-term planning.

Limitations in the Infrastructure

The ethanol plant infrastructure is inefficient, meaning they are not fully equipped to manage ethanol blends. This constraint will fail market penetration.

Competing the Global Race

The ethanol industry has to compete with other renewable energy sources and alternative biofuels. Innovation is essential to stay competitive in the vast energy market.

Advancements in Technology

New technology is emerging in the market and the industry has to keep up with these advances to succeed in the crowded market. By leveraging these technologies, the ethanol industry can achieve efficiency and profitability. One such example is ethanol ERP.

Features of Ethanol Manufacturing ERP

The procurement management system features monitors and manages the procurement and usage of raw materials, such as grains or sugarcane, ensuring a streamlined supply chain for ethanol production seamlessly. Track the origin, quality, and quantity of raw materials to maintain consistency in ethanol production and meet regulatory standards.

ERP aids in optimising the ethanol manufacturing process through real-time monitoring of production stages, allowing for adjustments to enhance efficiency and minimize downtime. This feature leverages insights into the production cycle, helping identify bottlenecks, reduce waste, and improve overall productivity.

Ethanol ERP implements robust quality control measures throughout the production cycle to ensure that the ethanol meets industry standards and regulatory requirements. This feature also ensures adherence to environmental and safety regulations, promoting a sustainable and compliant manufacturing process.

Effectively manage ethanol inventory levels, track storage conditions, and automate reorder processes to prevent shortages or excess stock. It helps in integrating with suppliers and distributors for real-time visibility into inventory movements, facilitating efficient supply chain management.

Traceability of ethanol batches, aiding in quality control and regulatory compliance. ERP for ethanol manufacturing industry provides easy serial and batch tracking features which helps in tracking the product in the supply chain system.

All the financial processes are streamlined which is related to ethanol manufacturing, including budgeting, cost tracking, and financial reporting. It also prov1ides insights into production costs, revenue, and profitability, enabling informed decision-making for the sustainable growth of the ethanol manufacturing business.

Upgrade Your Business DNA with Sage X3

Empower your team and elevate your results with ERP Software

Benefits of ERP Software for Ethanol Manufacturing Industry

Ethanol manufacturing ERP is the best remedy for businesses to achieve efficiency and growth faster. ERP can provide industry-specific solutions that can help businesses with seamless workflow and remove all the supply chain system bottlenecks. Let us look at some of the benefits of ERP systems for the ethanol Industry.

Boosts Productivity

There is a huge demand for ethanol in the market due to the demand for biofuels and flex-fuel. Hence, the workload for the ethanol industry is greater. However, implementing ERP for ethanol manufacturing industry will automate all the processes, save time by streamlining workflows and improve the productivity of the employees.

Accurate Maintenance of Product Consistency

ERP for ethanol manufacturing industry helps in setting precise parameters and generates consistent output. If the viscosity, density and other parameters are well balanced, it ensures the consistency of the product.

Asset and Inventory Management

For ethanol organic raw materials such as residue drops of crops and wood are essential. Ethanol ERP has the right inventory management system to manage it efficiently. ERP can balance and manage both materials efficiently.

Management of Formula and Recipe

ERP software for ethanol manufacturing industry can be formulated accurately following all the guidelines and seasonal variations. The tools and functionalities of the ERP can dynamically adjust parameters seamlessly.

Controls Production

ERP application for the ethanol industry will help in monitoring and tracking the entire production process. The visibility feature in Ethanol ERP helps in tracking all the activities of the production process which will help in establishing control.

Reduces Costs

Cost can be lowered as Ethanol manufacturing ERP streamlines workflows which helps in identifying areas where there is wastage. Resources are also allocated correctly in the right areas to eliminate wastage.

Integrated Data Across Departments

ERP for ethanol manufacturing industry unifies all the data from across the departments thereby improving collaboration and communication throughout the business.

Optimizes Supply Chain

Supply chain management in ERP has real-time visibility features that help in tracking all the functions of this system. This helps in improving supply chain, logistics, and distribution processes.

Raw Materials Planning

Ethanol manufacturing ERP has an efficient procurement management system module that helps avoid overstocking and stockouts.

Final Takeaways

ERP software for ethanol manufacturing industry is essential to streamline and manage the entire business functions. It is the best business management software to seamlessly manage the entire stages of ethanol production. In addition, supports make-to-stock and make-to-order tasks. Leverage the robust features of this technology to stay competitive and achieve continuous growth.

Sage X3 is an efficient tool to smoothly manage all the functions of the modern ethanol industry striving for innovation and success. It has robust features such as business intelligence, quality control, real-time data analysis and reporting, seamless integration with existing systems, analytical features, production scheduling, batch processing, and company-wide collaboration which helps in solving all the challenges of the ethanol industry. Implement this solution to achieve consistent productivity and growth.

Frequently Asked Questions

What is Biofuel?

Biofuel is a cost-effective and environment-friendly alternative to traditional fossil fuels. It is derived from different types of biomasses such as human and animal waste, agri waste, vegetable oils, forestry, filtered municipal waste, and dedicated energy crops, among others. With increasing prices of petroleum and concerns about global warming, biofuel is emerging as a great alternative to fossil fuels.

The use of biofuel is helping countries reduce their dependency on oil, and control greenhouse emissions. It is a carbon-neutral source of energy that can be used in existing diesel engines with no complex modifications. Thanks to its low viscosity rate, the engine lasts longer and offers optimum performance similar to fossil fuels.

What is Flex Fuel?

Flex Fuel is the combination of gasoline and methanol or ethanol. It powers flex fuel-run vehicles using the latest technological innovations. Vehicles powered with flex-fuel run on a combination of fuels. They use advanced technologies such as sensors to detect fuel blends and are capable of making automated adjustments on their own.

Flex fuel is considered a cleaner energy form due to no adverse impacts on the environment. It neither releases toxic fumes into the environment nor reduces the engine efficiency or performance. Increasing usage of flex-fuel allows companies to reduce their dependence on foreign oil, and obtain tax credits.

How Does ERP Software for Ethanol Manufacturing Industry Supports the Inventory And Supply Chain Processes?

Businesses across the world face various inventory and supply chain-specific challenges. Increased instances of stockouts result in lost sales opportunities and a negative brand reputation. In contrast, surplus stock can result in higher holding costs and reduced profit margins.

Ethanol ERP facilitates enhanced planning, analysis, and control of inventory and supply chain. It shows real-time insights into inventory levels, which allows the company to reduce the instances of stockouts and excessive stocks. It enhances the supply chain operations by facilitating forecasting and improving communication and collaboration with external stakeholders such as vendors and customers.

How Does Ethanol Manufacturing ERP Help Manage Costs And Maximize Resource Utilization?

Ethanol ERP brings efficiency into company-wide processes and streamlines all activities from raw material procurement, inventory handling, and payment confirmation to sales. The use of automation and reduced labor-intensive work allows employees to focus on core activities, and the company benefits from reduced costs.

It also helps companies to maximize resource utilization in various ways. For example, it analyzes the availability of required resources and ingredients to effectively schedule the production activities. It facilitates thorough planning, execution, and monitoring of the usage of pan-organization-wide resources, and the creation of customized project workflow to estimate & allocate the right resources.

Is It Possible to Integrate the ERP for Ethanol Manufacturing Industry with Legacy Systems?

With the advent of ERP, many businesses have realised that existing legacy systems are incapable of meeting their operational needs. Their scope is limited as they lack integration with various business operations. However, completely abandoning existing legacy systems may not be always possible. Some businesses may want to continue using legacy systems in combination with ERP.

It is possible to integrate the Ethanol ERP with legacy systems. A good ERP tool offers robust integration with existing systems to facilitate the real-time exchange of information. Such an integration can help your business avoid disruptions in regular business activities, analyze historical data, identify trends, and find areas of improvement.

Is Ethanol Considered a Biofuel?

Yes, ethanol is considered a part of the biofuel ecosystem. Unlike fossil fuels which require millions of years to produce from long-dead animals and plants, Ethanol is produced from living plant materials and dead animal waste. In India, it is created from sugarcane molasses. It is known as the first generation of biofuel technology.

Ethanol is widely used across the world due to the various advantages it offers. As it contains a higher level of oxygen, it holds little to no gummy deposits when used in high-compression engines. It keeps the fuel system of the engine clean.

Schedule Product Tour

"*" indicates required fields