What is Push and Pull Strategy in Manufacturing?

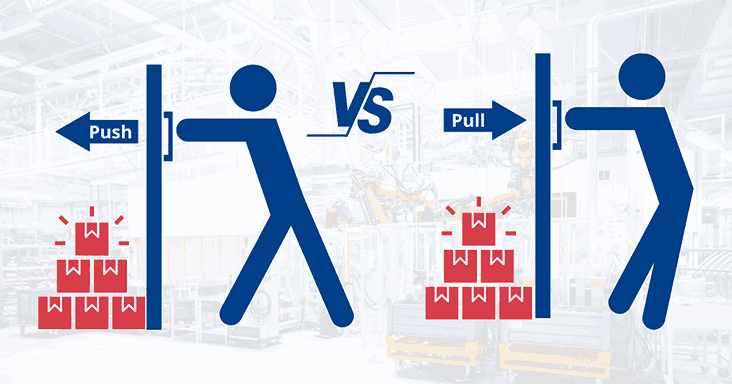

Push and pull strategy are two distinct manufacturing systems that help determine when the goods need to be manufactured to cater to market demand at the right time, and is achieved by aligning the inventory, production and distribution with the market demand.

In the push strategy, products are manufactured based on accurate demand forecasts using ERP software and pushed to the market when the sale occurs. On the other hand, a pull strategy involves the production of goods only when the manufacturer receives the customer order, thus, literally pulling the raw materials and inputs through the supply chain based on actual demand.

Ideally, the role of push and pull manufacturing system is to ensure inventory control while maintaining a competitive advantage. Whether you choose a pull or push strategy or opt for a hybrid approach, the focus stays on maximizing production efficiency and optimizing resources for ensuring operational profitability.

Next, we’ll discuss how the push and pull strategies work along with examples of each to help you understand the terms better.

How Does Push Strategy Work?

Push production strategy is a Make-to-Stock (MTS) manufacturing approach which primarily relies on demand forecasting for mass production of goods, leading to efficient and cost-effective production. As soon as the forecast is ready based on market predictions, a master production schedule is prepared. Accordingly, the raw materials are ordered and the manufacturing begins.

It is important to note that since push manufacturing is dependent on accurate prediction of demand, any considerable deviation from actual demand will lead to overproduction or underproduction of goods, leading to inventory management challenges. A pure push strategy is fairly common among consumer goods industries such as food and beverage, automobiles, electronics and pharmaceuticals.

Here’s an example of a push strategy. A chocolate bar manufacturer generates monthly and quarterly demand forecasts using historical sales data including festive demand patterns stored in the ERP system to generate an estimate of production quantity. Accordingly, the ingredients are sourced and the resulting production tasks such as recipe management, quality control and inventory management are all efficiently managed using a comprehensive ERP for food industry.

What Are The Advantages of Push Strategy in Manufacturing?

1. Economies of Scale

Bulk production allows manufacturers to reduce per-unit product costs because they have better negotiating power during bulk purchases and can utilise their existing resources at full capacity.

2. Simplified Planning

With demand forecasts in hand, the planning for procurement and production becomes quite simplified. Push strategy focuses on keeping the production cycle running and pushing the inventory to the market.

3. Product Availability

Push strategy enables enhanced customer experience because the stock is readily available to meet high customer demand without delays, thus reducing the lead time to service customers.

What Are The Challenges with Push Strategy in Manufacturing?

a. Overproduction Risk

The market is subject to demand fluctuations due to changes in trends or customer preferences. Consequently, manufacturers may end up producing much more than needed.

b. High Inventory Costs

Surplus or unsold inventory can occupy plenty of storage space and tie up excessive capital, which could otherwise be utilized for more productive activities such as starting a new product line.

c. Lack of Flexibility

Push strategies lead to manufacturers planning ahead and forming long-term procurement contracts, leaving little room for production changes unless you use one of the best ERP software in India.

How Does Pull Strategy Work?

In sharp contrast to the push strategy, the pull strategy is a Make-to-Order (MTO) approach where the production begins only when the order arrives. Pull strategy is common for products that are highly customized and cannot be produced without knowing the exact specification requirements of the customer.

This is why a pull strategy follows Just-in-Time inventory method, implemented using an agile manufacturing ERP software, which allows you to manage the order for a specific quantity and product type at short notice to align with customer requirements. The flow of materials in a pull strategy is triggered based on actual demand and not on anticipated demand as in a push strategy.

One of the best examples of a pull strategy is specialty chemicals industry where manufacturers have to produce complex chemicals with specific properties, such as the ones used in semiconductor manufacturing. Specialty chemicals are manufactured in small batches with the help of cutting-edge ERP for chemical manufacturing that allows high flexibility in production and supply chain management. Also, it is common for OEMs supplying components to different automobile manufacturers to use a lean manufacturing pull strategy to maintain production efficiency.

What Are The Advantages of Pull Strategy in Manufacturing?

1. Waste Reduction

By producing only what is needed, the pull strategy avoids overproduction, minimizes inventory costs, and ensures optimum utilization of resources, while increasing flexibility for customization.

2. Customer Satisfaction

Meeting specific customer requirements becomes faster using a pull strategy, as production is closely linked with customer demand for a product, ensuring customer loyalty and satisfaction.

3. Quality Control

Under the pull strategy, production volumes are relatively controlled, allowing for precise quality checks and smooth management of a diversified product portfolio with a customer-centric approach.

You Might Also Like: How ERP Improves Quality Control in Pharmaceutical Industry?

What Are The Challenges with Pull Strategy in Manufacturing?

1. Inventory Shortage

Pull system is prone to inventory shortage risks due to lack of inventory buffers. Disruption in the supply chain or sudden demand spikes makes it difficult to meet demand, leading to lost sales.

2. Supplier Coordination

When using a pull strategy, supplier relationship management has to be very strong so that your suppliers are willing to supply raw material in smaller quantities frequently and at short notice.

3. Demand Forecasting

In a pull strategy, though the order fulfillment begins only when the order is updated in the ERP software, forecasting accuracy remains crucial for production planning.

What is the Difference Between Push and Pull Strategy in Manufacturing?

| Push Strategy | Pull Strategy | |

| Production | Products are made in advance based on demand forecasts | Products are made only when needed based on actual customer demand |

| Inventory | Higher inventory levels leading to higher holding costs | Lower inventory levels due to just-in-time production |

| Flexibility | Less flexible due to fixed schedules and excess stock | Statement of Cash Flows |

| Risk of Waste | Higher risk of overproduction and waste | Lower risk of waste, only produces what is needed |

| Unique Advantage | Reach economies of scale | Mass production of customized products |

Hybrid Approach: Combining Push and Pull Strategies

A hybrid manufacturing system takes advantage of both push and pull strategies to optimize inventory levels while meeting customer expectations. Production processes which are common for parts manufacturing and sub-assemblies follow a push strategy to create work-in-progress inventory. Further processing of work-in-progress inventory and unique production processes will only take place based on the actual demand and customer specifications.

What Are the Advantages of Hybrid System in Manufacturing?

1. Demand Driven

Hybrid model helps improve responsiveness to demand, offering increased flexibility and customization. As soon as the order arrives, the production processes of the later stages can begin immediately. As a result, it is easier to scale production based on changing demand patterns.

2. Inventory Efficiency

The chances of inventory shortage and overstocking are considerably reduced under the hybrid system of production. Your inventory management software gives you all the information you need on stock levels, ensuring storage cost efficiency and better utilization of resources.

3. Reduced Lead Times

Another important advantage of push and pull strategies is the significant reduction in lead times. By pushing inventory closer to demand signals and pulling it based on real-time orders, you can quickly respond to customer requirements.

What Are The Challenges with Hybrid System in Manufacturing?

1. Operational Complexity

When you use push or pull, you are quite certain of your production strategy. However, to be successful in a hybrid system, you must strike a perfect balance between push and pull using a comprehensive ERP application, which automates business processes and reduces operational costs.

2. Data Accuracy

Due to the operational complexity, it becomes even more important to ensure data accuracy and precise reporting throughout the organization. And when you process that data using business intelligence software, that’s when you gain in-depth insights to make more informed decisions.

3. Advanced Planning

Do your suppliers know when you are going to place another order? It is only when you minimize communication gaps with all your suppliers through advanced capabilities of procurement software that you can balance operational flexibility and efficiency.

Also Read: What are the Six Types of Manufacturing Processes?

What is a Suitable Example of Push and Pull Strategy?

As India eyes rapid manufacturing growth, a combination of push and pull factors can definitely work in its favor, positioning India as a global manufacturing hub. Let’s look at some of the real-life scenarios where the hybrid push and pull strategy works the best.

1. Uncertain Demand

When the demand for the product is uncertain, the upstream production or early production stage is processed using a push strategy to create an inventory buffer. Thereafter, the pull strategy is applied during advanced production stages, offering flexibility of customization.

2. Higher Lead Time

Products that take a longer time to manufacture due to high lead time of procurement and multiple production stages are best suited for the hybrid model as it helps reduce overall lead time while ensuring product availability.

3. High-Value Products

You don’t want to tie up excessive capital in inventory when products are high-valued or complex in nature. In such situations, a combination of push and pull strategies balances cost management and production efficiency.

What Are The Key Factors To Consider When Choosing A Manufacturing Strategy?

To decide when to use a push, pull or hybrid strategy, bear these key factors in mind that will help you to a conclusive decision.

1. Product Type

If your product is a perishable or high-cost item, you will have to ensure freshness and minimize waste while balancing the inventory levels.

2. Demand stability

How stable is the demand for your product? Do you have to review your forecasts every week? Conducting a demand analysis by integrating ERP software ensures better forecasting and planning.

3. Inventory Storage

Imagine an automobile manufacturer storing 1000 unsold cars in the warehouse. Besides knowing the right inventory levels, you must evaluate customer expectations for lead time and customization.

4. Supply Partners

Your suppliers are a crucial link in your supply chain. Strategic partnership and strong relationship with suppliers go a long way in ensuring the stability of supply of raw material and inputs.

5. Current Model

Assess KPIs in your ERP solution such as inventory turnover rate, lead time, and on-time delivery rates to track the success of your existing model and identify areas for improvement.

Also Read: What are Inventory Valuation Methods?

Shape the Future of Your Production with Sage X3

Understanding the basics of push and pull system of manufacturing is crucial to form long-term production plans and serve your customers cost-effectively and on time. The right strategy ensures that every aspect of your production aligns with your company’s objectives.

Whether you want to implement a push or pull strategy or opt for a hybrid model, Sage X3, an industry-leading ERP software, is your trusted partner to boost production and inventory efficiency across business units while managing all the financial aspects of your global business operations.

FAQ

1. What Is Push and Pull Strategy in Manufacturing?

Push and pull strategies are production planning strategies that help manufacturers decide on how much to produce and when to produce to serve the customers better. A push strategy mainly relies on demand forecasts whereas a pull strategy is dependent on actual customer orders.

2. Which Strategy Is Better in Manufacturing: A Push Strategy or A Pull Strategy?

Both strategies have their pros and cons. Choosing the right strategy depends on a number of factors such as the type of product or services offered, demand stability, inventory levels to avoid high storage costs and dead inventory, and your relationship with suppliers.

3. What Are The Main Benefits of Push And Pull Strategies?

Push strategy tremendously reduces lead time as the product is ready to be shipped from your warehouse. A pull strategy eliminates the need for finished goods inventory storage as the production begins when the order comes, offering flexibility to meet specific customer requirements.

4. How Does A Pull Strategy Help Reduce Waste in Manufacturing?

A pull strategy is a lean manufacturing strategy following a Just in Time and Kanban manufacturing approach where the production cycle is closely linked with demand, thus reducing waste at every level of production.

5. How Can Manufacturers Shift From A Push To A Pull System Effectively?

To shift from push to pull strategy requires a careful analysis of demand and customer requirements. By implementing demand forecasting, adopting lean manufacturing principles and tracking real-time inventory using an ERP system, you can make a successful transition.