What is Purchase Order (PO)?

Purchase order is a legal document sent by a buyer to a vendor or supplier, enlisting complete details of the products that the buyer has agreed to purchase from the supplier, including a list of items, quantities and prices, as an official confirmation of order placement on mutually agreed order fulfilment terms.

In other words, a purchase order clarifies to the supplier what the buyer wants to purchase before any transaction or product delivery takes place. The supplier is liable to fulfil the order only after the PO order number is generated, after which he starts preparing for order fulfilment to meet the order deadline.

What is PO Number?

A PO number is a unique purchase order no generated by the purchaser, with the help of ERP software, specific to the order being created. This PO number is referenced throughout all forms of communication between buyers and sellers and makes it easy to track transactions and order updates.

With retail e-commerce sales slated to cross $6.3 billion worldwide in 2024, according to Statista, creating an automated purchase ordering system is essential for retailers to manage their purchases and fulfil customer orders on time seamlessly.

Now let’s find out how to create a PO.

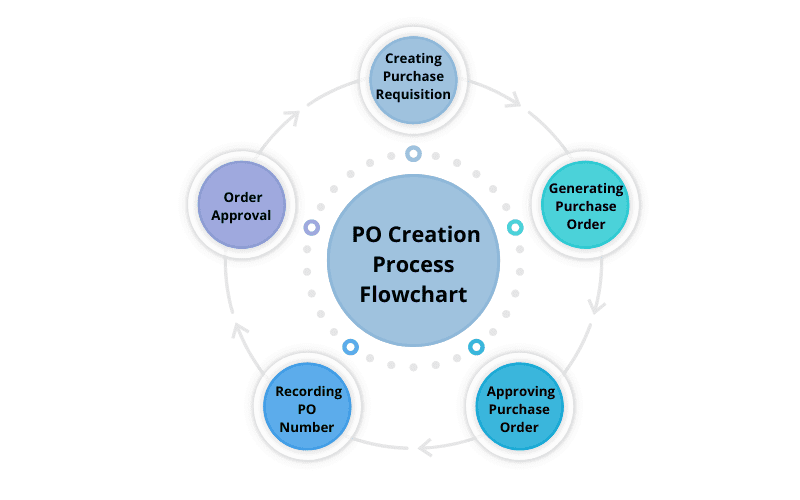

How to Create a Purchase Order?

A streamlined purchase order process ensures that every small or large purchase made by the company is systematically done, without creating any confusion among the stakeholders within and outside the company. The objective is to create a standardized procedure for procurement to improve efficiency and achieve complete visibility into the purchasing process.

Here are the necessary steps followed while generating a purchase order.

1. Creating Purchase Requisition

A purchase requisition is a purchase request document generated internally within an organization by a staff member who wants to procure goods or services for the organization. ERP software solutions offer an effective way to create this initial purchase requisition document including the details of items to be bought and the reason for making the purchase, allowing senior staff to review the purchase request.

2. Generating Purchase Order

After the senior team members review and approve the purchase requisition request, the authorized staff generates a purchase order using procurement software , which consists of the PO number along with all the necessary details regarding the purchase, including buyer company name, product names, quantity, prices, seller name and shipping address, and is forwarded to the seller.

3. Approving Purchase Order

On receiving the purchase order, the seller goes through the details listed in the PO and communicates and reconfirms with their production department before giving final approval to the buyer on their ability to fulfil the order on time. At this stage, the supplier is free to request the buyer for modifications in the terms and conditions, before finally accepting, which becomes legally binding on both parties.

4. Recording PO Number

Once the seller officially accepts the purchase order through email or any other acceptable mode of communication, the buyer moves ahead and records the PO number in the system. Soon after the order delivery, the purchase order is marked fulfilled. Every stage of the PO is automatically recorded by the ERP system, thereby enhancing efficiency and reducing manual errors in the ordering process.

5. Order Approval

The order fulfilled by the seller is reviewed and approved by the buyer. On approval of the goods or services received by the buyer, the seller generates an invoice. Matching of the purchase order no and invoice ensures a smooth payment to the supplier. Eyeing long-term strategic partnerships, many companies utilize accounts payable software to manage multiple suppliers effortlessly.

What Does PO Include?

A purchase order is incomplete without mentioning the below-mentioned necessary details. Here are the various components of a purchase order, including a PO number.

1. Contact information

The purchase order contains contact details of both the vendor and buyer, including their names, addresses, phone numbers and emails.

2. PO number

A purchase order number or PO number is a unique multi-digit code specific to a purchase order and is mentioned in every official communication between the supplier and the buyer.

3. Order Date

Purchase orders must include the date on which the order is generated. Order date helps keep track of order fulfilment deadline from the date of purchase and helps both parties in journal entries.

4. SKU

Stock Keeping Unit or SKU is a unique alphanumeric number, assigned to variations of a product in terms of shape, color, size and more, that helps both parties keep track of inventory.

For example, if the product ordered is fasteners, all the variations of the product like stainless steel fasteners 316L, stainless steel fasteners 304L, and so on will have a different SKU number.

5. Technical Specifications

Technical specifications describe the technical details of the product for the supplier, exactly how the buyer wants it to be.

For example, a buyer ordering specific fasteners would mention whether they want cold forged or hot forged fasteners along with hardening, tempering and thread type details.

6. Quantity

Whether ordering products, the buyer has to specify the quantity for each product along with its technical specifications. It aids the manufacturing suppliers in planning batch manufacturing and fulfilling order on time.

7. Price

The price is a crucial item in a PO number as it would vary depending on its technical specifications. To avoid future dispute and confusion, every detail about pricing and cost breakup is explicitly mentioned as discussed and agreed between the parties.

8. Shipping Address

A buyer could be a manufacturer with multiple production facilities in a region and has ordered raw materials from a supplier using purchase orders. The purchase order includes the exact shipping address of the buyer to ensure that the product is shipped to the right destination.

9. Taxes

There are various taxes levied by the government on the manufacturing of goods. The details about Goods and Services Tax (GST), excise duty and sales tax are given in the purchase order. Irrespective of the complexity of the purchase order, ERP software for manufacturing automates tax calculations for multiple purchase orders, eliminating the need for manual intervention.

10 . Shipping Charges

Shipping cost has to be borne by either party engaged in the transaction. As the shipping charges have to be usually paid to the forwarding agent, they should be mentioned as a separate entry in the PO and not to the purchase price.

11. Delivery Date

The purchase order has to add in the order delivery date which ensures that the supplier strictly meets the order deadline, without causing any obstruction to the supply chain of the buyer.

Additionally, a fixed order date makes sure that the purchaser makes adequate arrangements for receiving and storing inventory. For this, the supplier also sends an advanced shipping notification to the buyer, before sending the shipment.

12. Payment Terms

Depending on the credit period extended to the buyer, usually 60 days, the due date of payment forms an essential part of the purchase order. In the case of multiple purchase orders, the due date of payment for a particular order can be easily tracked by the supplier using the PO number of that order. If there is any advanced payment involved or discount terms for payment before the due date, make sure to enter the details.

Also read, Role of ERP in manufacturing

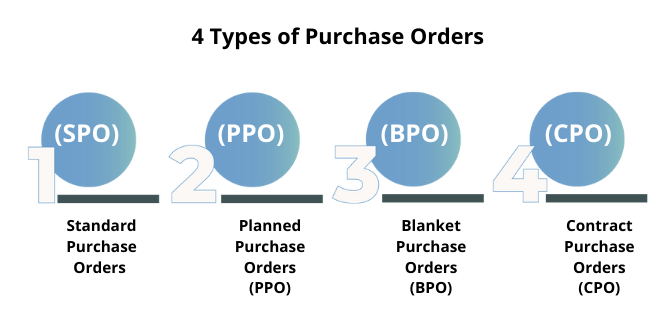

What are the Types of Purchase Orders?

1. Standard Purchase Orders (SPO)

A standard purchase order is most commonly used in instances where the buyer is making a one-time purchase and has complete clarity on order requirements. This kind of order includes details about product description, price, quantity, delivery schedules, and shipping location for every product in the purchase order.

For eg. a firm setting up a new office that wants to install 100 cassette Air Conditioners in 3 ton and 4 ton capacities, will raise an SPO with a supplier, clearly mentioning product model and descriptions, price and quantity of each model along with the delivery date and location.

2. Planned Purchase Orders (PPO)

A planned purchase order (PPO) is almost the same as a standard purchase order, including the list of products, product description, price and quantity. However, it only provides a tentative delivery schedule to plan future requirements from a single supplier on a long-term basis.

For eg. a manufacturer anticipating consumption of 1000 kiloliter of lubricants next month across two manufacturing plants would raise a PPO with a supplier, and send the exact delivery date and location when the need arises, and the supplier will readily be able to send it.

3. Blanket Purchase Orders (BPO)

A blanket purchase order, also known as a standing order, includes the list of products but eliminates details on quantity and in many cases, the item price from the PO. This is a long-term agreement between the parties, where the buyer is not sure of the exact quantity required in the future. The price is negotiated when the demand arises.

For eg. a motorcycle OEM making chassis following a make-to-order production strategy, will require stainless steel sheets based on the order received from the motorcycle manufacturing company. With daily fluctuations in steel prices, inventory management software makes it smooth and transparent for buyers to negotiate raw material prices based on the required quantity.

4. Contract Purchase Orders (CPO)

A contract purchase order is a purchase order type where the parties sign a long-term agreement after discussing terms and conditions for payment and delivery such as credit period extended, which party would bear freight charges, etc. However, it does not include a list of items, quantity, price, delivery date and location.

For eg. if a motorcycle OEM makes chassis using steel, aluminum, carbon fiber or titanium, and his raw material inventory type differs based on demand, he would prefer to sign a CPO with his suppliers and raise a detailed PO when the need arises. Many manufacturers are increasingly prioritizing supplier relationship management to meet their long-term goals.

Comparison of Purchase Order, Invoice & Sales Order

| Purchase Order | Invoice | Sales Order | |

| Purpose | Document to place the order for specified goods | Document to request payment for specified goods | Document to confirm the sale and arrange for product delivery |

| Issued by | Buyer to seller | Seller to buyer | Seller to buyer |

| Dates | Tentative delivery date | Payment due date | Delivery date |

| Issued When | Issued before product delivery | Issued after product delivery | Issued before product delivery |

| Document Number | PO number | Invoice number & PO number | Sales order number & PO number |

| Tracking | Used by buyer to track orders | Used by seller to track payment | Used by seller to track sales |

What are the Benefits of a Purchase Order?

1. Enhance Productivity

Purchase order provides you visibility into the procurement process, allowing you to track products that were ordered and also avoid order duplication. An online purchase management system further automates the ordering of products that are regularly required by the organization, by automatically generating a PO when the inventory reaches a minimum threshold level.

2. Manage Inventory

Purchase orders allow you to efficiently track and plan your inventory, especially when you use just-in-time inventory strategy to minimize your holding costs. PO helps you to view what is due for reordering and also plan future inventory requirements.

3. Track Suppliers

Purchase orders are effective documents to sort and filter information about multiple suppliers a business is dealing with daily. It further helps you to prevent order delays and make sure that suppliers follow order fulfilment timelines.

4. Centralized Record

Whether it is a purchase requisition or purchase orders created by an ERP system, everything is stored in a centralized repository, giving you access whenever you need to track the items. Acting as a permanent record of all the purchases made by the business, it even helps you to perform cash flow projection.

5. Prevent Legal Disputes

A purchase order PO has everything listed about the products, including a list of products, technical specifications, prices agreed upon and quantity required, to prevent disputes arising from wrongful product delivery. Both buyer and seller can refer back to the details mentioned in the PO and resolve the confusion.

6. Monitor Liabilities

Purchase order PO allows businesses to track every expense whether it is planned or unplanned and make sure it is recorded in the current liabilities to effectively manage their cash flow statement. Monitoring the cost of production becomes simpler as purchase orders include details on pricing which can be used to calculate raw material inventory cost even before actual delivery.

Summing Up

A purchase order is a legally-binding document with a unique purchase order number, generated by a buyer confirming the purchase of goods to the supplier, who can then make adequate arrangements to supply goods as specified in the order. Creation of a standard purchase order starts with a purchase requisition request and ends with order approval by the buyer.

Sage X3 ERP with its robust built-in capabilities allows buyers to streamline their ordering process, helping you generate a specific purchase order type with custom terms and conditions, and managing and tracking multiple POs for various suppliers and vendors. Thus giving you absolute control over your procurement and ordering process while reducing administrative burden and costs.

FAQs

1. What is PO Number Definition?

PO number meaning is that it is a unique order number associated with a particular purchase order, issued by a buyer to the seller with details about products to be purchased along with their price, quantity and delivery dates.

2. What is PO Number Full Form?

PO number is a Purchase Order number, a unique order number specific to a purchase order.

3. What is PO?

A purchase order or PO is an official document issued by buyers to vendors or sellers, giving details about products they want to purchase, including product price, quantity and other terms and conditions agreed upon.

4. What does PO Mean in Business?

PO meaning in business is that it is a legal document issued by a purchaser to the seller and is issued before product delivery. It simplifies order management and tracking.

5. What is a PO Used For?

- Track and manage orders and inventory

- Track past purchases

- Track suppliers and prevent disputes

- Plan future purchases

6. What is a PO vs. Invoice?

- PO is issued by the buyer; invoice is issued by the seller

- PO is issued before product delivery; invoice after delivery

- PO contains PO number; invoice contains both invoice and PO number

- PO contains the product delivery date; the invoice contains the payment due date