What is Procurement Cycle?

Procurement cycle is a set of procedures followed by an organization to efficiently purchase goods and services they need to fulfil customer orders at the right time and in the right quantities while ensuring that they nurture long-term relationships with suppliers.

In other words, the purpose of the procurement cycle is to have a standardized and efficient procurement process that saves the organization’s time and money, and also so that it can be replicated for the purchase of any goods or services needed by the organization in the future.

What are Different Procurement Types?

Before discussing the various steps of the purchase process, it is important to have an understanding of three different types of procurement utilized by a business. They are direct procurement, indirect procurement, and services procurement.

1. Direct Procurement

The procure-to-pay or p2p process facilitated by ERP software in procuring and paying for goods and services which are consumed as part of its core operations is known as direct procurement. The goods procured in this scenario are parts of the end product that reach the customers of the business and directly add to the product cost.

For eg. A bicycle manufacturer obtaining brakes and handles from its suppliers is engaged in a direct p2p cycle. These products become part of the bicycle and the partnerships formed are usually long-term relationships with suppliers to secure a continuous and trustworthy parts supplier for the business.

2. Indirect Procurement

Indirect procurement, on the other hand, are products and services which are consumed by the business to facilitate the routine operations of the business. Although the goods procured in this case do not form part of the end product, companies have to follow the purchase process to procure such goods. While indirect procurement forms a significant share of the cost of production and thus has to be taken into account, these costs do not add directly to the product cost.

For eg. When the machinery used to manufacture the end product breaks down or its parts need to be replaced, which can be costly and necessary to run the machinery, the business is engaging in indirect procurement. Similarly, plant repair, fuel, lubricants, electricity and other utilities consumed are part of indirect procurement.

3. Services Procurement

In contrast to direct and indirect procurement, services procurement refers to the services utilized by a business which may or may not form part of the core operations, but are required to support the operations and functioning of the company. Services procurement follows the same set of the purchase process as involved in direct and indirect procurement.

For eg.

- Hiring a GST tax consultant for filing taxes and meeting regulatory compliance.

- Consulting an ERP advisor to understand how ERP benefits your business.

- Buying an Annual Maintenance Contract to service the machinery.

Difference Between Direct, Indirect and Services Procurement

| Types of Procurement | Definition | Example | Business Impact | Procurement Process |

| Direct Procurement | Purchasing raw materials and goods directly involved in the production of a company’s products | Raw materials, components, and machinery | Directly affects the production process, product quality and product cost | Often involves long-term contracts and strategic sourcing |

| Indirect Procurement | Purchasing goods and services that are not directly tied to the production process but are necessary for running the business | Office supplies, maintenance, and utilities | Indirectly supports the business operations and employee productivity | Typically involves routine purchases |

| Services Procurement | Acquiring services from external providers that are needed to support the operations and functioning of the business | Consulting services, IT support, and cleaning services. | Supports various business functions and operational efficiency | Usually involves detailed service contracts and performance monitoring |

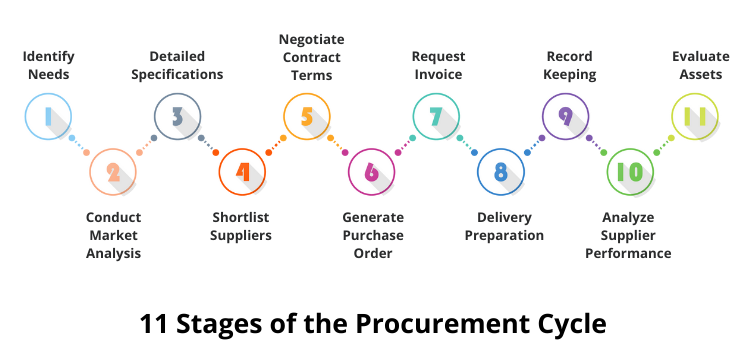

11 Stages of the Procurement Cycle

According to PwC’s 2023 US Risk Perspectives Survey, 57% of professionals are seeing better decision-making as a result of implementing tech applications, including identifying and mitigating risks associated with the procurement process. Implementing procurement software makes the procurement process efficient while optimizing costs and minimizing risks.

Though every business can have differences in their p2p process based on the industry they are operating in and the goods or services they offer, the 11 steps in the procurement cycle mentioned here are the most commonly used in almost every major purchasing decision. The different stages of the procurement cycle are as follows:

1. Identify Needs

The first step in the procurement cycle involves evaluating your products and services requirements. What is the product that you are looking for? Do you need this product from the market? What if you manufacture this product yourselves? Is it a one-time purchase or an ongoing requirement of your company? Consider the quantities you need and the cost you’ll have to incur.

Answering these questions early in your p2p process will give clarity before your procurement team goes ahead with formal purchase request approval from the purchase manager.

2. Conduct Market Analysis

The second step in the p2p cycle involves studying the market based on your requirements. Are the supplies located in India or abroad? What kind of products are available in the market? Do they meet your exact requirements? Get an estimate on pricing. Make a list of suppliers. If possible, classify the suppliers based on the production strategy they follow. Whether it is Make-to-Assemble, Make-to-Order or Make-to-Stock. Find out if they offer custom solutions.

3. Detailed Specifications

After you are finished with the preliminary market study using Request for Information (RFI) from suppliers, the next step in the procurement cycle is to list the detailed specifications of the product required. Even if you don’t find the exact product you are looking for, stating the exact dimensions helps you get the next best alternative while searching for a supplier. And when you Request for Proposal (RFP), it gives more transparency on your precise requirements and challenges involved to your existing or prospective suppliers who could be willing to provide custom solutions in a bid to foster a long-term relationship with you.

4. Shortlist Suppliers

Narrow down your initial list of suppliers to a select few. This shortlist has to be carefully evaluated as you head closer to supplier selection. Request for Quote(RFQ) from the selected suppliers with the built-in features of an online procurement management system to identify suppliers that meet your budget. But remember, cost cannot be the only factor when evaluating suppliers.

Remember, you have to consider a host of other parameters like the supplier’s market reputation, and specific strengths such as some suppliers going the extra mile to provide superior service experience to customers. Ask for testimonies, past records on order delivery and product quality. Find out how keen they are in forming long-term partnerships.

5. Negotiate Contract Terms

When forming a contract, carefully examine the terms and conditions as your financial decisions will have direct implications on your customers. Always work towards forming a win-win partnership for both parties involved. Mention details on product quality guidelines, pricing and delivery timelines in your agreement. State the credit period extended to you and other payment terms. Include complete information on standard operating procedures to be followed by the supplier. If needed, you can get assistance from a legal deal negotiator to smoothly sail through your p2p cycle. Sign a contract once you are negotiation terms are settled.

6. Generate Purchase Order

No purchase should be initiated before formally issuing a purchase order. Purchase orders are a critical component of the p2p cycle. These official documents contain complete technical specifications, a list of items, prices and quantities, issued to the supplier confirming the order placement by the buyer. Instead of manually generating a purchase order, you can automate the purchase order generation process with the help of an ERP system, especially when you are placing recurring orders. The automated system auto-generates a PO and sends it to the supplier when inventory falls below preset threshold levels.

7. Request Invoice

All payments are made only after an invoice is raised by the supplier. Maintaining multiple suppliers and and purchase orders necessitates an accurate financial record of invoices. Accounts payable software does an excellent job of tracking all purchase orders and matching them with corresponding invoices, ensuring that all your payments are made on time and that you maintain transparency and accuracy in current liabilities.

8. Delivery Preparation

Preparing for product delivery is a critical step in the procurement cycle where you have to know where the products are going to be received and stored. You don’t want a large shipment to arrive suddenly at your facility with no clue on how to manage it. Ask your supplier to send Advanced Shipment Notification (ASN) so that your warehousing team is prepared to receive the order. Use a Warehouse management system to streamline product receipt and distribution and efficiently track the movement of inventory.

9. Record Keeping

Record keeping is a mandatory exercise to document your entire p2p process for permanent records. Ensure that all the documents used during the p2p cycle are safely and securely stored. From purchase orders and invoices to purchase contracts and all Request for Information (RFI) and Request for Quotes (RFQ) documents, everything can be systematically recorded in a centralized ERP system, eliminating the need for manual organization of documents. Accurate record-keeping ensures you can assess inventory purchased during previous accounting periods to plan and project future purchasing requirements.

Also Read: ERP As Document Management System

10. Analyze Supplier Performance

Continuously evaluating supplier performance makes sure that they meet product quality requirements laid out in the contract. More than that, you have to assess if the supplier is fit to form long-term relationship with your company. Many companies follow supplier relationship management to nurture strategic partnerships. As we know, every supplier is different. Knowing their production capacity expansion plans, financial strengths, and risk-taking abilities are vital parameters for a manufacturer dependent on critical parts on a few major suppliers.

For example, as part of performance evaluation during the purchasing cycle, it is common practice among large OEMs to send their purchase manager to the supplier’s manufacturing facility for inspection of goods. This ensures that product meets the quality guidelines during the production stage and the buyer can avoid unnecessary delays due to quality check failure at a later stage.

11. Evaluate Assets

Regular assessment of physical and digital assets using asset management software after the p2p process is over, guards you against unforeseen procurement demand in the future. Periodic preventive and predictive maintenance avoids unnecessary disruption in operations at the last stage, allowing you to systematically plan the new purchase.

Difference between RFI, RFP & RFQ:

| Term | Meaning | Purpose |

| RFI (Request for Information) | A preliminary document to gather general information about products or services. | To gather information about potential suppliers or solutions offered. |

| RFP (Request for Proposal) | Detailed document outlining specific project requirements and seeking detailed proposals. | To solicit formal proposals from vendors that meet specific project needs and criteria. |

| RFQ (Request for Quotation) | An advanced stage document for pricing and availability of specific products or services. | To obtain pricing and delivery terms for a particular purchase. |

Also Read: What is Maintenance, Repair and Overhaul?

What are the Advantages of Procurement Cycle?

Integrating a step-by-step procurement cycle in your purchase process has several advantages for your business. Here’s what you’ll gain:

1. Risk Mitigation

Risks associated with procurement can suddenly derail the production activities of the organization with direct implications on customer relationships. A well-defined procurement process ensures that the supply of every raw material is tracked, keeping companies aware of what to buy and when to buy to maintain supply continuity.

2. Process Efficiency

A strategically aligned procurement cycle can drive significant process efficiencies, leading to cost and time savings for the business. Knowing your major suppliers helps you negotiate better contractual terms. No business would want to randomly choose a supplier that offers cheaper raw materials without fully ensuring the stability and reliability of supply.

3. Operational Transparency

Imagine placing an order for 100 different items from different suppliers. Without a systematic procurement process and ERP system, gaining clear visibility into supplier operations will be impossible. Moreover, a procurement manager can know for sure which items are in short supply and need urgent replenishment.

4. Competitive Edge

Procurement is not only about sourcing the products timely and cost-effectively but also about delivering competitive advantages for the company. When your company forms a major strategic alliance with a supplier who builds innovative products, you can generate outstanding value for your customers, paving the way for long-term success.

What are the Limitations of the Procurement Cycle?

In keeping up with the procurement challenges faced by growing businesses, most organizations would be keen to implement a procurement cycle if not for certain limitations that make it a not-so-attractive proposition.

1. Elaborate Process

The procurement cycle follows a systematic process of establishing the need, purchase requisition, approvals, shortlisting of suppliers and so on, which although highly efficient, may seem elaborate and extensive to employees not used to it and hence may be discouraged from following such a system.

2. Inadequate Training

Like any new system, this IT-driven procurement process requires adequate training of employees to understand the different features of procurement management software and how it facilitates collaboration among employees from other departments. Resistance to change can act as a roadblock.

3. Existing System

Every organization has an existing purchase system in place. The new system, besides adding new functionalities, should be able to fully integrate with the existing IT system, tools and spreadsheets so that the transition is smooth and not disruptive to procurement operations.

What are the Factors Affecting Procurement Cycle?

While having an efficient procurement cycle drives exceptional benefits for a company, its success truly depends on a host of other factors.

1. Budgetary Constraints

Certain supplier partnerships may require a commitment of bulk volume purchase which leads to significant cost reduction in product price. However, due to various other financial obligations, a business without deep pockets may not want to go ahead with the deal and lose out on the opportunity for strategic purchase.

2. Technical Limitations

Building technological capabilities in procurement operations offers unparalleled benefits for a company. Deploying an ERP system, and having relevant IT infrastructure and support staff ensures that you have adequate resources to leverage data, gain real-time insight and make faster and informed purchase decisions.

3. Management Support

One might argue that procurement is solely a function of the purchasing department. On the contrary, implementing a procurement cycle needs full determination and focus of the management to make it part of the organization’s culture to the extent that no purchase is conducted without due diligence and that every staff member follows a documented procedure for purchase approvals.

Streamline Your Procurement Life Cycle With Sage X3 Software

To establish a cost-effective and timely purchase process, it is essential to follow a procurement cycle that systematically guides you in completing a purchase. Whether the purchase is part of direct, indirect or services procurement, following the purchasing cycle ensures that you don’t skip the key steps in choosing a reliable and trustworthy supplier.

Sage X3 ERP is an advanced ERP solution equipped with all the features to organize your entire p2p process, helping you with selecting suppliers, auto-generating purchase orders, tracking your accounts payable, producing financial reports along with comprehensive order management so that you never go wrong with something as important as procuring quality goods and services for your company.

FAQs

1. What is Procurement Process?

Procurement process refers to the workflow followed by a business to purchase goods or services from suppliers and vendors to minimize risk associated with purchasing decisions.

To define procurement process, we can use an example of a manufacturing firm that wants to set up IT hardware and software systems to manage its operations. As they have never had any experience with IT setup, they would require a systematic purchasing cycle for successful project implementation.

2. What are the Stages of the Procurement Cycle?

A purchasing cycle follows these 11 steps to complete a purchase. The steps are as follows:

- Identify Needs

- Conduct Market Analysis

- Detailed Specifications

- Shortlist Suppliers

- Negotiate Contract Terms

- Generate Purchase Order

- Request Invoice

- Delivery Preparation

- Record Keeping

- Analyze Supplier Performance

- Evaluate Assets

3. What is a Procurement Life Cycle?

The sequence of steps followed by an organization to acquire material and services from external sources is known as the procurement life cycle.

4. Why is the Procurement Cycle Important?

Following the procurement cycle ensures that a business minimizes its procurement costs, reduces risks associated with purchase and improves efficiency of the procurement process.

5. What are the Documents Used in the Procurement Process?

The most commonly documents used in the procurement process are Request for Information (RFI), Request for Proposal (RFP), Request for Quotation (RFQ), invoice, purchase agreement, and Purchase Order.