What is Manufacturing Execution System?

Manufacturing Execution System is a process-driven solution that acts as a functional layer between an ERP and Process Control Systems to analyze, manage, and document key aspects of the entire manufacturing activity, and gain a deeper understanding of the potential deviations & discrepancies for higher compliance and quality enhancements.

Unlike traditional MES that provided a limited functionality of only tracking and documenting, modern-day MES have gone through a transformative change. They offer capabilities to resolve industry-specific challenges such as data analytics, IoT & AI integration, and predictive maintenance, among others.

What are the Features of a Manufacturing Execution System?

Now that we’ve discussed what is MES, let us go through some of its distinct features.

1. Data Collection

One of the key features of a Manufacturing Execution System (MES) is data collection. MES supports instantaneous data collection from different sources such as equipment, quality control systems, and labor. It provides critical insights that allow manufacturers to optimize the workflow, avoid delays in the production activity, and maximize the output.

2. Process Standardization

Standardizing the manufacturing process becomes easier with the Manufacturing Execution System. It promotes smooth material flow and better control over the machine parameters. Adopting standardization throughout the manufacturing process brings in consistency in the quality of the production output, and the same level of customer experience.

3. Quality Management

With the Manufacturing Execution System, businesses can implement robust quality control and inspection tools to ensure their products are of the highest quality, and adhere to the latest industry norms & government regulations. By mitigating safety risks to the customers, they can reduce fines, penalties, and criminal proceedings.

4. Performance Analysis

Another major feature of the Manufacturing Execution System (MES) is comprehensive performance analysis. MES facilitates comprehensive tracking and monitoring of the production process starting from the acquisition of the raw materials and quality control to conversion into finished goods. Businesses can use Key Performance Indicators (KPIs) to gauge the deficiencies in performance and compare targets vs actuals through comprehensive reports.

5. Work Order Management

The Manufacturing Execution System promotes the smooth flow of orders throughout the production cycle. Such a smooth flow of orders helps reduce production delays and additional expenditures. MES lets you manage your work requests, schedule them for later, and increase employee productivity. Work Order Management also increases an asset’s lifespan and availability of your assets.

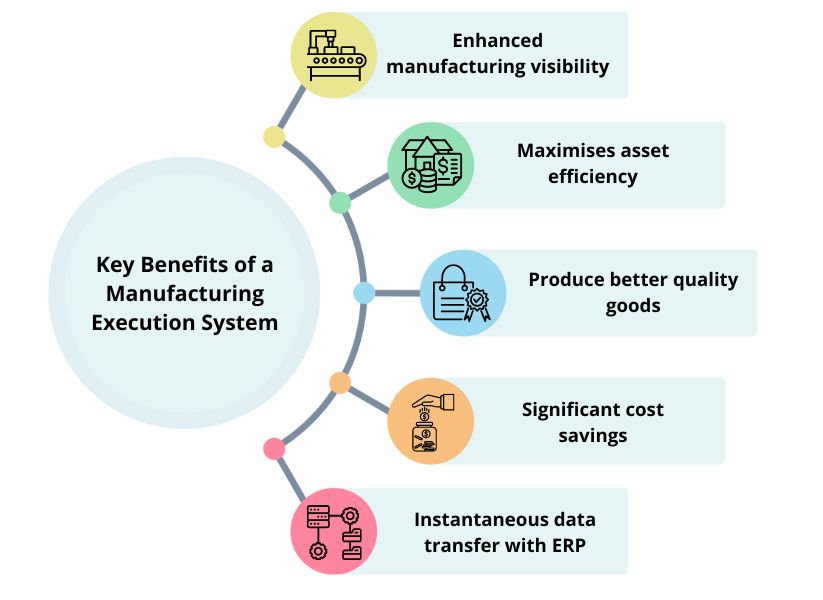

What are the Key Benefits of a Manufacturing Execution System?

As we’ve discussed what is manufacturing execution system is and what are its features, let us now discuss what key benefits it offers to manufacturers.

1. Gain Unprecedented Visibility

The Manufacturing Execution System provides unprecedented visibility throughout the manufacturing processes. With real-time information about different events in the manufacturing process, they can identify the room for improvement and take corrective measures to reduce wastage, limit downtimes, maximize output, and improve quality & compliance.

2. Operational Equipment Effectiveness

Another benefit of adopting a manufacturing execution system is that it increases the operational equipment effectiveness and manufacturing lead time. It allows manufacturers to become responsive to new market trends & changes, align to their product customizations, and meet their pre-planned production requirements.

3. Prevent Market Recalls

The Manufacturing Execution System supports lot number & serial number tracking to identify the source of manufacturing defects and minimize the amount of product recalls. It allows your business to meet quality assurance goals, modern industry standards, safety checks, and stringent regulatory requirements.

4. Production Efficiency

Implementing a Manufacturing Execution System ensures your business never returns to the paper documentation again. It brings transformative changes in your manufacturing process from digitization of production data, cost savings, and reduction in human errors to adherence to sustainable practices.

5. Sync Data with ERP

The Manufacturing Execution System supports real-time syncing data with an ERP implementation. The integration between these two robust, highly-adaptive, and intelligent systems offers a host of benefits for your business from production scheduling, raw materials tracking, and reducing data entry, to making accurate projections about the production outcomes.

New Trends in Manufacturing Execution System (MES)

By integrating MES software with advanced technologies, they become more modular, service-oriented, and integrated. Let us see how:

1. Mass Production

MES software also allows manufacturers to focus on customized production instead of mass production. For example, mass personalization — building highly-tailored products for multiple customers wasn’t possible earlier.

2. Smart Factories

Manufacturers are adopting new ways to interact with products, devices, and equipment autonomously without any geographical boundaries. This is done with the help of sensors and instant collection & distribution of information.

3. Personalized Manufacturing

Another popular trend among the manufacturers is adoption of Personalized Manufacturing. It focuses on Predictive Maintenance, elimination of waste, reducing manufacturing costs, and constantly identifying the room for improvement.

Revolutionizing Manufacturing through MES & ERP Integration

MES and ERP are two indispensable solutions for modern businesses. While MES primarily focuses on efficiently tracking, managing & documenting production activities, the ERP Software brings a 360-degree visibility into the business operations, and supports production planning, materials requirement analysis, and analytical & forecasting activities, through its integrated set of modules & in-house tools.

Here are the key benefits of integrating MES and ERP:

1. Accurate Demand Forecasting

One of the foremost benefits of this integration is fast and efficient decision-making. Manufacturing Execution System and ERP integration allow businesses to mitigate supply chain risks, detect seasonal patterns amid fluctuations in demand & supply, and pave the way for maximizing profit margins.

2. Business Analytics

While MES records detailed machine logs and digital master logs, ERP consolidates data from different departments within the organization and provides powerful business intelligence capabilities. Adopting both these technologies helps your business eliminate data entry, reduce human errors, and increase operational efficiency.

3. Prevent Rush Orders

Fulfilling Rush Orders may not be easy. The supply of materials may arrive late, employees may make mistakes due to stress, machines may develop defects or delivery partners may fail to deliver the product during the expected timeline. A solid inventory management system automatically notifies you every time your inventory levels reach a certain threshold to prevent Rush Orders.

4. Inter-connected Systems

With MES & ERP integration, your business benefits from inter-connected systems that transmit data in real-time. This is usually made possible with the use of Internet of Things (IoT) devices to facilitate effective communication between multiple device systems. Ultimately, your business mitigates the risk of errors and misinterpretations, and benefits from reduced machine downtime.

5. Enhanced Customer Satisfaction

The integration between the Manufacturing Execution System and Enterprise Resource Planning ERP provides a holistic view of the business operations and a Single Version of Truth. Timely access to authenticated information enables decision-makers to make informed decisions to meet customer expectations. With timely order fulfillment and better quality standards, the business gains from a loyal customer base.

Concluding Thoughts

In today’s highly competitive & ever-changing business environment, manufacturers are realizing the need to integrate manufacturing execution system and manufacturing ERP to their advantage. Integrating these systems allows manufacturers to make data-driven decisions, maximize their returns, and better respond to rapidly changing consumer trends & market circumstances.

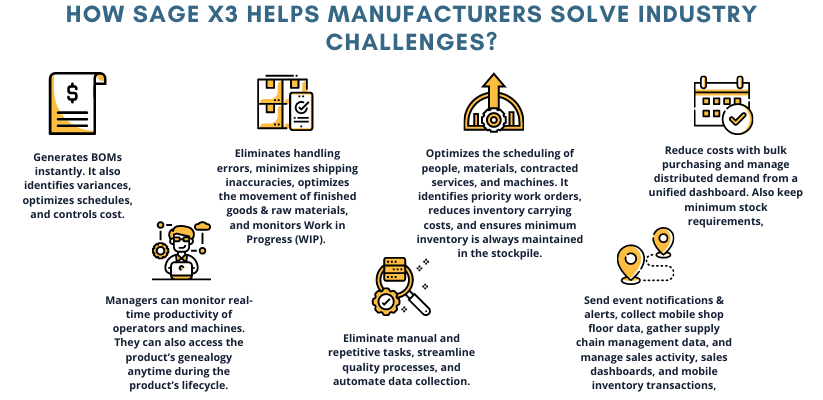

Sage X3 is an indispensable solution for modern manufacturers that are looking to take advantage of technological advancements to improve manufacturing speed, accuracy, and forecasting capabilities. It comes with a host of modules that help you achieve the highest level of precision, accuracy, and decision-making.

FAQs

1. What is the Definition of Manufacturing Execution System?

MES system meaning is that it is a production-centric system that provides control over the processes involved in the manufacturing activity to lower the manufacturing cost and improve the quality of the output for higher customer satisfaction and strict regulatory adherence.

2. Who Uses the Manufacturing Execution System?

As per our what is manufacturing execution system section, a Manufacturing Execution System (MES) is commonly used by manufacturers operating in complex and highly regulated industries that require strict adherence to various Government compliance regulations such as aerospace & defense equipment manufacturers, manufacturers of medical devices, food & beverage producers, and pharma companies, just to name a few.

3. What Distinct Features to Look for While Selecting an MES?

The capability and customizability of each MES may differ. While selecting an MES, look for shop floor control tools that are needed for job tracking & routing. Your MES should also provide quality assessment capabilities required to ensure end-to-end compliance with the complex & ever-changing regulatory aspects. Furthermore, it should be able to bring efficiency into the inventory management functionality.

4. What are Some Challenges Faced During the Implementation of MES?

Manufacturers may face a range of challenges during implementation of the Manufacturers Execution System (MES). Integrating MES with the existing systems such as ERP, loading historical datasets, and aligning the newly set up MES with the existing systems may be challenging tasks. Furthermore, the company will need to train its employees for effective use of the new system.

5. How is MES Different than CMMS?

Both Manufacturing Execution System (MES) and Computerized Maintenance Management System (CMMS) differ in functionality. As we already discussed under the what is MES section, MES focuses on optimizing the manufacturing activity and bringing transparency & accountability for higher compliance. In contrast, CMMS manages asset repair & preventive maintenance activities to enhance asset lifespan and increase the asset turnover ratio.