Inventory Management requires a lot of planning to effectively function without any bottlenecks. Just-in-time inventory management is crucial to increase efficiency and lower inventory costs for the company. A study by the International Federation of Accountants says this strategy can reduce costs by 25%. Businesses have adopted this technique to boost productivity and stay competitive in the current market conditions. It is a crucial technique to achieve efficiency in supply chain operations.

Inventory is the core business function and has to be closely monitored. JIT Inventory Management Software is essential for both small businesses and large enterprises. Further, this inventory management strategy has many benefits which will be discussed in this blog.

What is Just-in-Time Inventory?

In short, this strategy for inventory management is also known as JIT inventory. It is an important production method where the products are manufactured only if it is required. As a result, this can save on warehouse space and will lower inventory costs. Further, it ensures that the raw materials supplied are in alignment with the production schedules in the business. In simpler terms, it means that the raw materials, labour and goods will be purchased depending on the production schedules.

JIT inventory management can give an organisation major benefits by increasing the capacity to lower wastage, increase efficiency, and enhances competitiveness in changing market conditions.

JIT Inventory Management – Background

Just in time inventory approach is very useful to manage the entire production process resourcefully. It was first developed in Japan in the Toyota Manufacturing Plants. By adopting this strategy Toyota was able to overcome the challenges for survival as it was fully dependent on people, systems and plants. The main goal of introducing this concept was to minimise delays and ensure the timely delivery of goods to the customers.

The father of this concept was Taiichi Ohno and it originated from Japan. This approach will only work if all the labour, systems and resources are fully committed to increasing the efficiency and the profitability of the business. It helps to detect the demand and accurately manufacture products of high quality based on customer expectations. This will help in producing an accurate number of finished goods.

Also Read : What is Inventory Cycle Count?

Importance of Just-in-Time Inventory

Now we know that a just-in-time inventory is a significant method where the business receives only required goods from the supplier based on the manufacturing requirements. The method is applied to an organisation to minimise inventory holding costs and maximise inventory turnover.

In order to successfully apply this method, superior software such as an ERP system is required to closely monitor the demand, supply and movement of goods in the inventory. This will help in eliminating any errors and anomalies. Just-in-time inventory management is essential to devise plans for the entire supply chain process to successfully operate. Given below are some benefits of the JIT inventory management approach:

1. Minimises inventory wastage

It accurately helps in tracking the demand and assists in making the right amount of goods. Further, it reduces the overproduction of goods where the supply exceeds the demand. These unsalable goods will turn into dead stock and will occupy the warehouse space. Finally, the unsold goods will be stored in the inventory where the holding costs will incurred by the company.

In the JIT inventory management approach the order is placed for what is required, so there is no room for storing up unsalable goods.

2. Reduces warehouse holding cost

Occupying the warehouse place for a long time is expensive for the company. Excess inventory is dangerous for a company’s inventory as it can double the holding costs. With the just-in-time JIT inventory, the inventory goods are kept to a minimum based on the demand, this will reduce inventory holding costs. Hence, there is no risk of accumulating goods. Your inventory can be balanced well if the just-in-time inventory is adapted well for your company.

3. Gain more Inventory Control

One of the biggest challenges in the company is to achieve control of your inventory. However, adapting the JIT model has its own set of advantages. Just in time JIT inventory works based on the demand-pull. Hence, it has full control over the inventory and the manufacturing process. This will help in producing the right amount of goods in the inventory and reduce the production of slow-moving items. This approach is flexible for companies as it will help the business to produce the right amount of goods in the ever-changing market demands.

4. Importance to Local Sourcing

In the just-in-time JIT inventory method, a product is manufactured only after the order is placed. So, the company has to rely on local suppliers to make timely delivery of the finished product to the customer. In addition, local sourcing is the best option as it will reduce the transportation cost and time. This leads to a demand for numerous supplementary enterprises to operate simultaneously, consequently bolstering the employment rates within that specific demographic.

5. Investing in Smaller Amounts

In the JIT inventory management model, fewer stocks are manufactured and stored in the inventory. As a result less working capital is needed for procuring finance. So, if the stocks are stored less in the inventory, the ROI (Return on Investment) of the enterprise will be higher. Another significant aspect of this method is that it follows the concept of ‘right first time’. The manufactured product is crafted with high quality that it doesn’t require rework and inspection repeatedly.

Further, JIT inventory management enables to reduce costs by eliminating the need to rectify errors in the selling of an item.

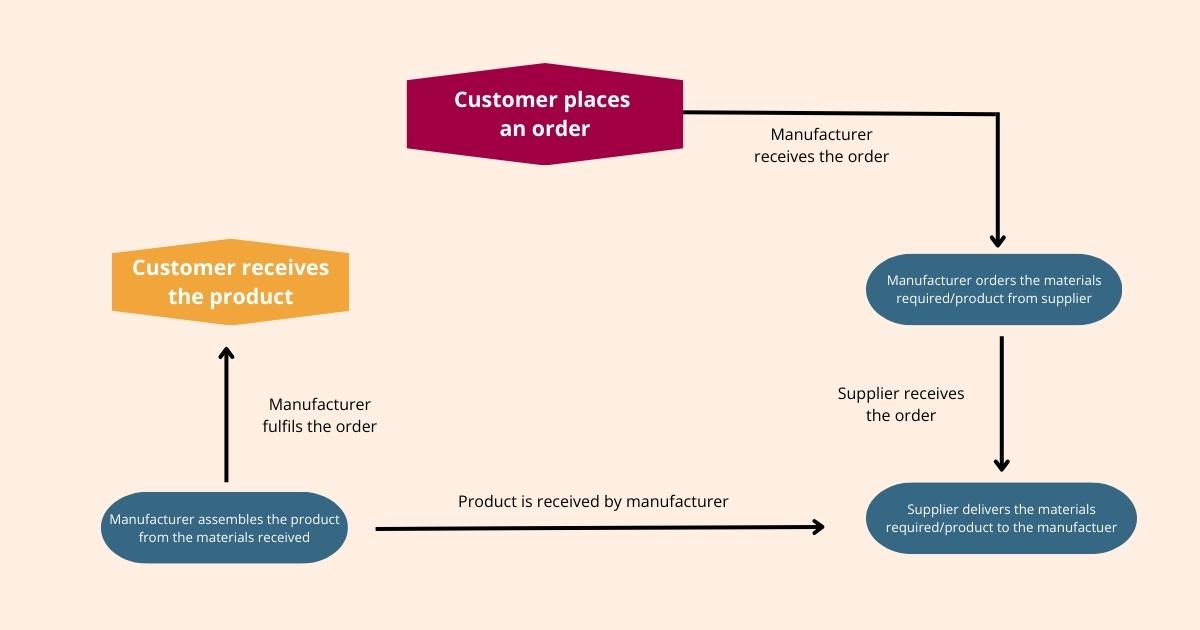

How Does JIT Inventory Management?

We have already discussed how Just-in-time inventory will help businesses in multiple ways. The foremost advantage is that it will reduce wastage and lower costs. Manufacturers also have found this method to improve customer satisfaction, manage customer complaints and free up warehouse space sooner.

With the just-in-time method, it is easier to find reliable suppliers who can be trusted for long-term contracts. Also note that just in time JIT is an interdependent system. It is a system which mainly focuses on the flow of information and goods across the company.

Many organisations apply the just-in-time inventory management method distinctly, however, let us discuss some of the consistent sequences.

→Design

The just-in-time process begins with the assessment of design. Design is the fundamental of the JIT which involves product design, process design, employees and manufacturing planning. These plans are created to avoid disruptions, reduce wastage and build a reliable system. Design paves the way for flexibility.

→Manage

In any company, there will be a team to assess the quality of the manufacturing process. The team is known as Total Quality Management (TQM). TQM looks into matters concerning setting up standards for quality control which means to improve the quality of the product and the services. It also defines the labourers’ roles and responsibilities. Finally, they also decide the schedules and the capacity for the production.

→Pull

Introduce Kanban and additional signalling techniques to educate the team about production and withdrawal methods. As a part of this initiative, aim to decrease batch sizes.

→Establish

It is crucial to establish a good relationship between vendors. Vendors are also important factors for the success of the business. Review the list of vendors and then sign the contract with the vendor who will be suitable for your business. Negotiate with them regarding the lead times, delivery expectations and usage metrics.

→Fine-Tune

Comprehend your existing inventory and establish policies and controls to reduce superfluous handling and transfers.

→Build

Educate your team regarding this process and inform them about all the skills and capabilities required to complete this process.

→Refine

In this step, try to ease the process. Begin by simplifying the design, reduce the total parts required and the assembly process has to be reviewed. Standardise the entire process here.

→Review

All the problems can be rectified sooner within the just-in-time inventory by applying the quality metrics and measures. Using these identify the root cause of the issue and can instantly apply improvement strategies. To improve further, tracking trends can also be helpful.

This is how a just-in-time inventory works commonly. Following these will help to meet customer expectations which will boost the profitability of the company.

JIT Inventory Methodology

Just-in-time inventory ensures efficiency in operations by adopting various techniques. The lean approach centres on refining organization, emphasizing precision, adopting smaller batch sizes, enhancing visibility, promoting cellular manufacturing, and employing a pull-based system instead of a push-based one.

Listed below are some of the techniques involved in the just-in-time Load uniformity inventory:

> Order – Largely physical and organisational discipline is maintained.

> Better Quality – Stays vigilant and finds ways for continuous improvement.

> Reduced time – If you want your production to function without bottlenecks, be ready for instant changeover when customer demand fluctuates.

> Small Lot Size – For a just-in-time inventory, small Lot sizes are better. As a result, it helps in minimising forces inventory, lowers carrying costs, easily manageable storage space and opens the door for easier analysis and rework.

> Load uniformity – In order to stabilize fluctuations and achieve a level daily schedule, a levelling technique is utilized.

> Flow balance – Workload is distributed evenly among personnel in the flow scheduling technique.

> Diversified skills – If you have cross-trained labourers for the production, then you can assign them to different areas to keep the production operating without any halt.

> Visibility for control – Visibility of inventory operations is the key to balancing inventory levels. Communication tools such as Kanban can provide real-time updates about the inventory.

> Strong Supplier Network – JIT inventory will be a success if the business has a strong vendor relationship.

> Pull System – In this system, the products are replaced after they are used to create another product.

> Comprehend fitness – JIT inventory speeds up the production process as they are designed for each process correctly.

> Logical plant layout – If the design is product-oriented, the assembly will become a lot easier.

> Worker Immersion – It is important for every employee to contribute and support the team’s efficiency goals.

> Cell Manufacturing – In this an environment is created where groups can manufacture more products quickly which also contributes to reducing waste.

> Ongoing Maintenance – Tailored JIT workspaces expedite production. Each station draws output from the preceding one as required, guided by a master schedule or customer demand.

Also Read : What is Inventory Cost? – Types and Examples

Disadvantages of JIT inventory

The main disadvantage of just-in-time inventory is that it can cause disruptions in the supply chain. For example, if the vendor fails to deliver the product on time, the entire process will fall apart as raw materials are crucial for all functions to work properly. So, the entire process will be stalled because of this disruption.

JIT Inventory Management Software

Do you want your company’s JIT to enhance operations? Explore JIT inventory management software. It automates processes, streamlining the implementation of this strategy for greater efficiency and effectiveness in your operations.

ERP system is also an advanced solution to enhance the just-in-time JIT inventory functions seamlessly.

Conclusion

Just-in-time inventory is the best method for companies to balance their inventory levels effectively. It also helps them to produce the right amount of goods based on the demand. It simplifies inventory management, reduces storage costs and minimises wastage. However, the company must ensure that it doesn’t impact the sale of the product.