What is Digital Supply Chain Management?

Digital Supply Chain Management establishes a network of inter-connected systems and adopts digitization to automate supply chain operations and support proactive & strongly data-driven decision-making for higher efficiency and growth.

ERP Software is an all-encompassing solution that enables businesses to harness the power of modern technology & tools to become adaptive & proactive in their decision-making, enhance transparency & accountability, and outshine their competitors.

Overview of the Digital Supply Chain Management Industry

According to a research report released by Grand View Research, the Digital Supply Chain Management industry is estimated to be $2.49 Billion in size. It is forecasted to grow at a CAGR of 12% during the period of 2023-30.

Several factors are expected to contribute to its growth including the ever-increasing use of IoT devices, increasing reliance on Predictive Analytics, and growing popularity of Business Intelligence Tools.

Essential Components of Digital Supply Chain Management

Let us have a look at some of the key components of Digital Supply Chain Management.

1. Data Analytics

Data analytics is one of the most important components of digital supply chain management. It plays a vital role in trend identification, inventory optimization, and strategy building.

2. Concurrent Collaboration

Another important component of the Supply Chain Digital is real-time collaboration between different elements involved in the supply chain activities, viz. Manufacturers, wholesalers, retailers, and so on. This brings transparency into the operation and promotes the free flow of key information.

3. Cloud Computing

Use of the cloud technology enables different teams to get real-time insights into all aspects of the digital supply chain from production to customer fulfillment. Businesses across the world deploy a Cloud ERP to eliminate bottlenecks in the supply chain and keep the process running smoothly without disruptions.

4. Robotics & Automation

Robotics and automation streamline work that is repetitive in nature and frees up human staff from hazardous & dangerous activities. The AI-powered algorithms are also used by businesses for route scheduling and reducing the amount of time taken by supply chain activities.

5. Internet of Things (IoT) Devices

Internet of Things (IoT) devices are wirelessly inter-connected with each other to facilitate real-time exchange of information such as the machine temperature, room temperature, and weather data, among others.

6. Digital Cybersecurity

Another important aspect is ongoing threat detection and efficient handling of cybersecurity risks. This may involve a range of practices such as activating an organization-wide Firewall protection, using military-grade encryption standards, and building a secured network infrastructure.

Prominent Features of Supply Chain Digital

As we’ve already discussed what is Digital Supply Chain Management and what are its components, let us now discuss its prominent features.

1. Digital Vendor Management

Streamline every aspect of the vendor management process, analyze vendor performance, and nurture vendor relationships. Digital Vendor Management also lowers the onboarding time and minimizes the potential for human errors.

2. Inventory Tracking

Gain a holistic view of your company’s inventory, and track it through a centralized platform. Get better prepared to identify & mitigate market risks such as unexpected demand surges, unavailability of raw materials, and changing customer expectations.

3. Accounts Payable & Receivable

Digitize your cash flow forecasting, mitigate risks, and improve relationships with your suppliers and customers. Streamline AP Automation & AR Automation, and get better control over your upcoming cash inflows and outflows. The Dynamic Discounting helps you with early payments and improving financial liquidity.

4. Real-time Collaboration

The Digital Supply Chain Management facilitates real-time insights to different employees & teams engaged in the supply chain process. With a centralized channel of communication, your employees gain access to complete & accurate information.

5. Autonomous Robotics

The use of robotics & automation increases the operational efficiency of your company as robots work 24*7 with no potential for human errors. Autonomous robotics has completely transformed the traditional process of supply chain.

What are the Advantages of Digital Supply Chain Management?

Digital Supply Chain enables businesses to build an integrated, agile, and scalable infrastructure to ensure smooth supply chain activities. Here’s how:

1. Up-to-the-Minute Insights

One of the key benefits of Supply Chain Digital is that it reduces hurdles in the collection and sharing of information, and speeds up the logistical process. For instance: With real-time & accurate weather information, route planning becomes easier than ever.

2. Personalized Marketing Campaigns

Categorize your customers into different segments, and run personalized marketing campaigns to cater to their different needs. Such a tailored strategy ultimately results in higher conversion rates, improved customer experiences, and profit maximization.

3. Scalability & Adaptability

Other benefits of ERP in Supply Chain Management include scalability & adaptability. With rapid growth in the scope of your business operations, you don’t have to worry about performance issues and limited data capacity.

4. Improved Supply Chain Efficiency

Best ERP Software in India minimizes delays in the supply chain processes and improves the order processing time. Reduction in the delivery hurdles and faster order fulfillment ultimately result in higher customer satisfaction.

5. Expedite Payments Collection

Improve the accuracy of the billing and payments collection process, reduce manual labor work, and minimize the potential risk of bad debts. With a smooth inflow of payments from your customers, you can shrink your operational costs.

What are the Disadvantages of Digital Supply Chain Management?

Every technology has its own pros and cons, and so does SCM Digital. Let’s have a look at some of its disadvantages:

1. Lack of Employee Training

Lack of employee training is one of the foremost hurdles. Without training, your employees may lack the necessary skills required for the job.

2. Inaccurate Information

Without access to key information at your fingerprint, you may not be able to achieve your intended objectives and strategic business goals.

3. Cybersecurity Threats

With increasing instances of ransomware attacks and data breaches, businesses need to deploy additional capital and workforce to secure their network infrastructure.

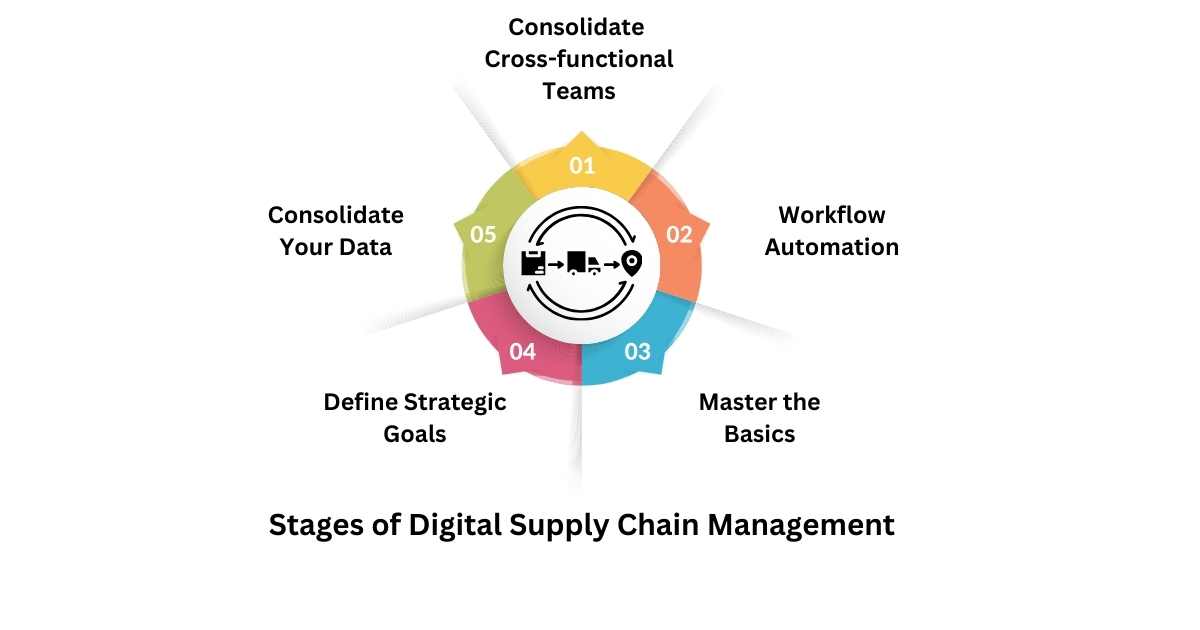

Stages of Digital Supply Chain Management

Now, let us go through the procedure to achieve the Supply Chain Digital.

1. Master the Basics

First things first, do basic research about any potential issues in your supply chain operations and look for various ways to fix them.

2. Consolidate Your Data

Consolidate your data from different departments within your organization such as purchase, sales, inventory, and customer support.

3. Define Strategic Goals

The next step is to define the short-term & long-term strategic goals of your business. Make sure that these goals are measurable so that you can track the progress over a period of time. Set realistic goals that can motivate & inspire employees & teams.

4. Consolidate Cross-functional Teams

Now that you’ve completed initial planning, consolidating data, and setting up your objectives, the next step is to bring together cross-functional teams within your organization.

5. Workflow Automation

Make the best use of the automation to streamline long & tedious tasks such as calculating safety stock of inventory. Workflow automation benefits in different ways such as enhancing reliability, accuracy, and productivity.

Difference Between Digital Supply Chain & Traditional Supply Chain

| Digital Supply Chain | Traditional Supply Chain | |

| Concept | Digital Supply Chain relies on the use of modern technology such as AI, IoT devices, and cloud to streamline manual processes & increase efficiency. | Traditional Supply Chain significantly relies on manual labor work and traditional legacy tools that support limited automation & often lack efficiency. |

| Sharing of Information | Fast & instantaneous | Delayed |

| Reliability of Information | Highly reliable (Concurrent access to info) | Less reliable (Risk of data obsolesce) |

| Scalability | Highly scalable | Less scalable |

| Decision-making | Smart & informed decision-making with the use of ML, AI, Business Intelligence, Predictive Analytics, and Scenario Comparisons. | Prone to human errors, inefficiencies & inaccurate decision-making |

| Cost | Cost-efficient (Due to optimum use of resources & optimized logistical operations) | Costly (Due to a significant focus on bulk manufacturing, and a lack of automation) |

How Does SCM Digital Transform Various Industries?

Let’s understand the role played by Digital Supply Chain Management in various industries across India throughout the years.

1. Automotive Industry

The automotive industry deploys Automotive ERP to improve tracking & traceability into the inventory, eliminate manufacturing disruptions, and optimize supply chain activities. For example, IoT sensors can be used to track the machine’s condition and plan maintenance activities.

2. Manufacturing Industry

Manufacturing enterprises use the Manufacturing ERP to increase their operational efficiency, reduce production delays & disruptions, improve production quality, and achieve better outcomes.

3. Food Manufacturers

Food manufacturing businesses implement ERP for food industry to transform their everyday business operations, minimize waste, and improve food safety & compliance. It is a vital tool to stay ahead of the competitors and maximize business performance.

4. Retail Outlets

Various retail outlets across India including e-commerce ones benefit from sophisticated Supply Chain Management Tools. The Retail ERP is equipped with business-critical tools that let you manage front-end operations & streamline back-end processes.

5. Chemical Manufacturers

ERP for Chemical Industry is an exceptional solution that provides a consolidated view of your ERP for chemical manufacturing business and helps you combat real-world inventory challenges.

6. Pharmaceutical Enterprises

Pharma ERP Software has brought digital transformation to pharmaceutical enterprises. Maintain quality & regulatory compliance, detect non-conformances at every level, track your inventory by expiration date, and outshine your competitors.

Wrap Up

Building a robust supply chain management strategy has become vital for businesses across the world. Adopting such a strategy will require rigorous analysis of your key business operations, identifying areas of improvement, and taking strategic measures.

Sage X3 is a multi-functional & highly customizable solution that acts as a significant success factor for businesses of all sizes and types. It plays an instrumental role in the growth of your organization by building an effective supply chain collaboration network.

FAQs

1. How Does SCM Digital Transformation Reshape the Traditional Supply Chain Processes?

Digital transformation reshapes every aspect of the supply chain process. Here’s how:

- Streamline the collection, storage, and retrieval of data

- End-to-end visibility across different aspects of the supply chain process

- Process automation and process standardization

- Lower supply chain disruptions

- Enhance operational efficiency and reduce potential human errors

2. What are the New Trends in SCM Digital?

Here are some recent trends reshaping the future of Digital Supply Chain Management:

- Artificial Intelligence (AI): Businesses are leveraging data science and Artificial Intelligence (AI) to optimize supply chain activities.

- Precision Tools: Businesses are using sophisticated tools such as ERP Application to simplify complex business activities and improve visibility.

- Carbon-neutral Technologies: There is a growing awareness among businesses to adopt carbon-neutral technologies such as electric vehicles for sustainability benefits and minimizing the fluctuating energy price risks.

3. In What Way Does SCM Digital Differ for Hi-tech Companies?

A hi-tech company is said to be a company that relies on advanced technological applications and rapidly changing technology. The digital supply chain may significantly differ for such a company from its traditional counterparts. Let’s take a simple example. A hi-tech company may leverage modern technology & tools to allocate its resources for maximum utilization and bring its products to the marketplace as soon as possible.

4. What are Some Hacks to Tackle Challenges in Supply Chain Digital?

With increasing incidences of cybercrimes, there is a risk of digital information theft. Businesses can protect themselves from data breaches by selecting a reputed ERP Vendor who is known for adopting modern security protocols and has a longer industry experience. Similarly, they also need to invest in regular cyber audits and training their employees.

Additionally, before making a switch to the Digital Supply Chain, businesses need to take the raw material vendors into confidence and explain the benefits of making such a switch. It will benefit them with a shorter procurement cycle and seamless supply of raw materials with minimal disruptions.

5. How Does SCM Digital Promote Supplier Collaboration?

Here’s how the Supply Chain Digital promotes supplier collaboration:

- Build and nurture partnerships with your key suppliers

- Gain a 360-degree overview of all aspects of your supply chain operation

- Promote free flow of data between your company and its suppliers

- Enhance business performance & responsiveness

- Drive substantial profits and promote & nurture growth