What is Demand Planning?

Demand Planning is a process of estimating future demand for the company’s products and services through extensive analysis of historical sales data, market trends & patterns, and customer behavior.

Businesses across the world use ERP Software to take advantage of advanced statistical algorithms, avoid last-minute scrambles, reduce data bias, and make highly proactive decisions.

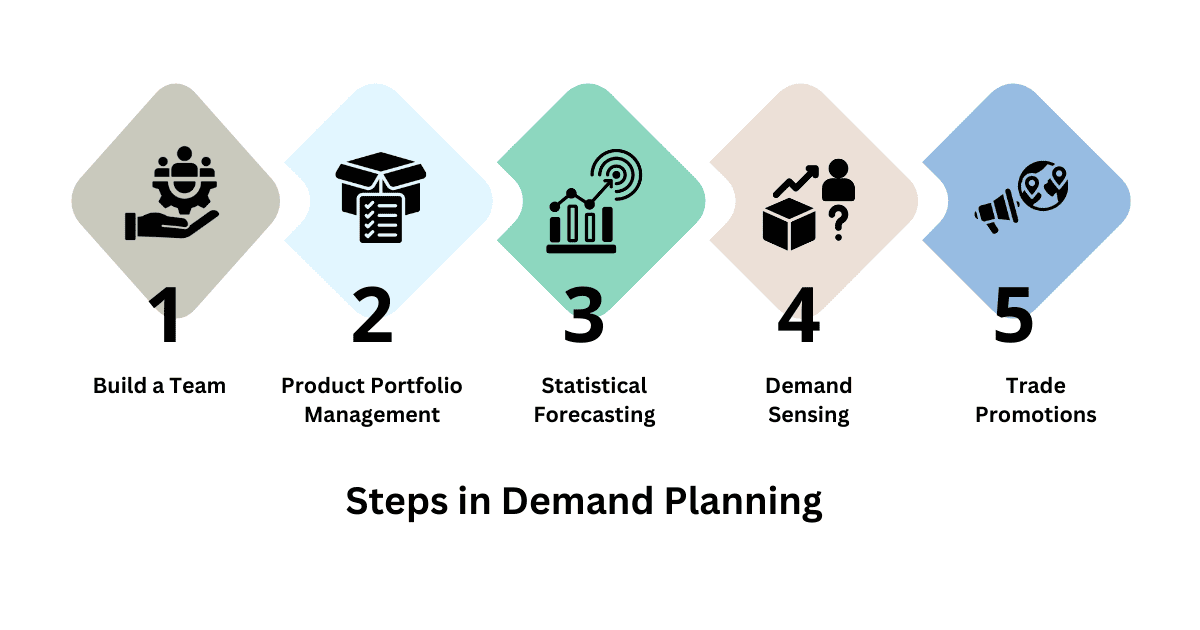

What are the Steps Involved in Demand Planning?

Demand forecasting in Supply Chain is more crucial than ever. Let us have a look at the steps involved.

1. Build a Team

Build a diverse team of employees from different aspects of business such as marketing & sales, operations, and production departments. This team will review any information you have pertaining to qualitative & quantitative sales models and provide realistic recommendations.

2. Product Portfolio Management

Product Portfolio Management details the complete lifecycle of the company’s products and the shifting nature of demand to the neighboring products. It includes a thorough analysis of the company’s products vis a vis market expectations.

3. Statistical Forecasting

Let’s take an example of pharmaceutical businesses that use Pharma ERP Software to perform extensive statistical forecasting. Their complex statistical algorithms help analyze historical demand for their products and make accurate predictions to reduce wastage and maximize profits.

4. Demand Sensing

A Sales Management System helps identify potential disruptions and fluctuations in demand using a combination of data sources to meet the needs of rapidly changing market requirements. In modern times, businesses use AI and ML for demand sensing.

5. Trade Promotions

Trade promotions help brands stand out from their competitors with their own specialized promotional offers, giveaways, and other marketing activities. However, it requires constant access to market information and usage of the extensive Key Performance Indicators (KPIs).

Benefits of Demand Planning

In today’s highly competitive business landscape, planning forecasting of demand is vital for a business’s survival and profit-making. Here are its key benefits:

1. Schedule Production Runs

Regular planning forecasting of demand is key to improving production efficiency and aligning your production strategies to meet ever-changing market requirements. A Manufacturing ERP lets you reduce wastage, allocate your resources, and minimize potential disruptions. It makes it easier to seamlessly procure raw materials using an Online Procurement Management System.

2. Optimum Inventory Management

One of the foremost benefits of an Inventory Management System is that it helps you keep ideal inventory levels, and minimize stock-outs & excess stocks. Reduce your inventory storage costs, increase efficiency in warehouse operations, and improve customer satisfaction.

3. Financial Planning & Budgeting

With timely access to key & strategic information using Financial Management Software, your business executives will be in a better position to make high-impact decisions, plan a clear roadmap for growth, and capture new highs.

4. Better Risk Mitigation Strategies

Let’s say, you’re a food business and you often scramble to fulfill customer’s demands. You can use an ERP for Food Industry to gain end-to-end visibility into the customer’s orders, build better risk mitigation strategies, reduce shipping costs, and improve profits.

5. Reduced Operating Costs

Reduce your operating costs by breaking down data silos, and improving the efficiency of various business processes. Thanks to ERP implementation, now your lower operating costs will translate into higher profit margins and sustained growth.

6. Boost Customer Confidence

With proper planning forecasting methodology, the business will be in a better position to fulfill customers’ expectations and reduce discrepancies in order fulfillment. Ultimately, it will result in a positive customer experience and higher confidence.

Limitations of Demand Forecasting in Supply Chain

Planning forecasting is important for businesses of all sizes and types. However, it has certain limitations.

1. Limited Data Availability

Lack of high-quality data is one of the major challenges faced by companies. Limited data corresponds to lower accuracies & increased risks.

2. Inaccurate forecasts

Timely and accurate demand forecasting is often difficult in nature and prone to various errors, misjudgments & inaccuracies, leading to wastage, higher production costs, and poor customer experience.

3. Influence of External Factors

Geo-political events (such as wars), natural calamities (such as floods & earthquakes), and other external factors can dramatically affect the accuracy of preplanned strategies.

4. Misaligned Strategies

Incorrect planning forecasting can lead to misaligned strategies & confusion. For example, the efforts of your company’s marketing department may not align with that of the production department, and so on.

Demand Planning Vs Supply Planning

Both Demand Planning and Supply Planning are an integral part of your business’s activities. Let’s understand the key difference between both of these strategies in simple words.

| Demand Planning | Supply Planning | |

| Concept | Demand Planning involves estimating the demand for the company’s products & services. | Supply Planning involves implementing various strategies to ensure market demands are fulfilled. |

| Objective | Better understanding of market requirements | Timely fulfillment of market requirements |

| Activities Involved |

|

|

| Key Stakeholders |

|

|

| Challenges |

|

|

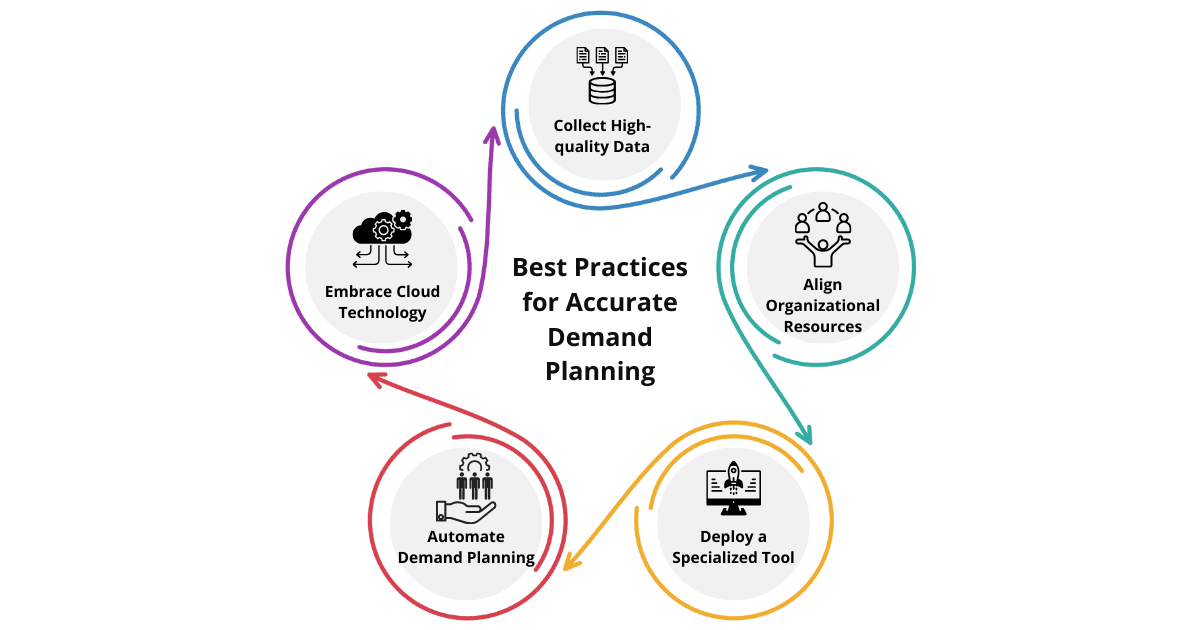

Best Practices for Accurate Demand Planning And Forecasting

Here are some tried and tested techniques to improve the quality & accuracy of planning forecasting:

1. Collect High-quality Data

Use various tools and technologies to collect high-quality data that you can rely on for solid decision-making. Business Intelligence Tools can be a game-changer here. You can automate various tasks such as data mining, data modeling, and transforming long & complex data into short actionable reports.

2. Align Organizational Resources

Ensure inter-departmental collaboration to align your organizational resources (including workforce & machinery) to achieve the strategic business objectives. Another benefit of Business Management Software is that you will be able to achieve higher production efficiency with a limited set of resources.

3. Deploy a Specialized Tool

Deploy the Best ERP Software in India to consolidate data across different departments, and reduce the instances of planning errors, inventory shortages, and delays & inefficiencies.

4. Automate Demand Planning

While dealing with large & complex data, manual work can be a massive time drain. Make the best of modern tools and technology to streamline various tasks in Demand Forecasting in Supply Chain such as gathering Market Intelligence, performing data analysis, and discovering trends & patterns, among others.

5. Embrace Cloud Technology

Leverage the power of Cloud ERP to get instant access to your data and share it with others in real time. The cloud offers massive low-cost computing power so that you don’t have to deploy your own internal IT infrastructure or worry about regular ERP maintenance or upgradation.

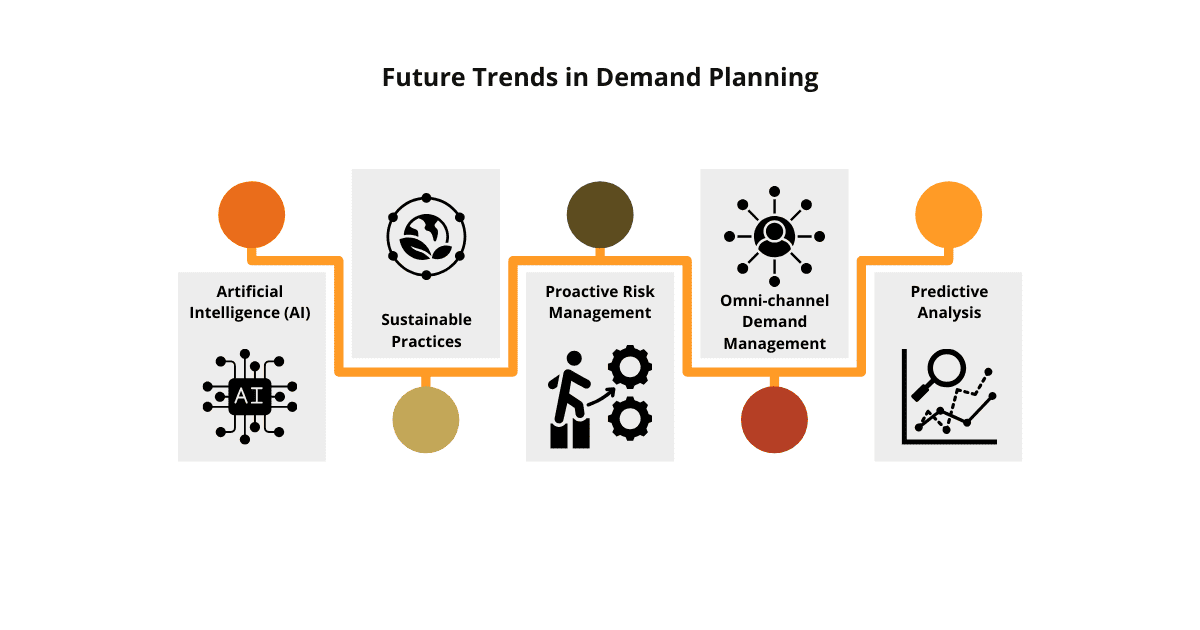

Future Trends in Demand Forecasting in Supply Chain

Now, let us look at some of the future trends in demand forecasting in Supply Chain.

1. Artificial Intelligence (AI)

Machine Learning (ML) and Artificial Intelligence (AI) are being increasingly used to predict customer behavior, process vast amounts of information, reduce waste, and perform comprehensive forecasts.

2. Sustainable Practices

Thanks to the growing awareness about environmental preservation, businesses are adopting various sustainable practices. This has helped businesses improve their brand image, lower energy consumption, comply with regulatory norms, and even attract new investments.

3. Proactive Risk Management

Let’s take a simple example of furniture companies. They use an ERP for Furniture Manufacturing to identify potential supply chain risks and mitigate them on time. By building a strong model for risk resilience, they are in a better position to handle unexpected events and minimize the intensity of shocks.

4. Omni-channel Demand Management

Another latest trend is an increasing focus on omnichannel demand management to improve the customer experience and manage your inventory efficiently. This ensures that your stock is available at the right place at the right time.

5. Predictive Analysis

Predictive Analysis involves the usage of historical data to identify anomalies and make predictions about the future demand for the company’s products and services. While Predictive Analysis may not be completely accurate, it helps you effectively handle uncertainties.

Wrap Up

Growing competition and rapid innovation have prompted businesses to perform demand planning on a regular basis. Modern-day businesses use a variety of sources including data mining and aggregation, to make the right amount of inventory available at the right place and at the right time.

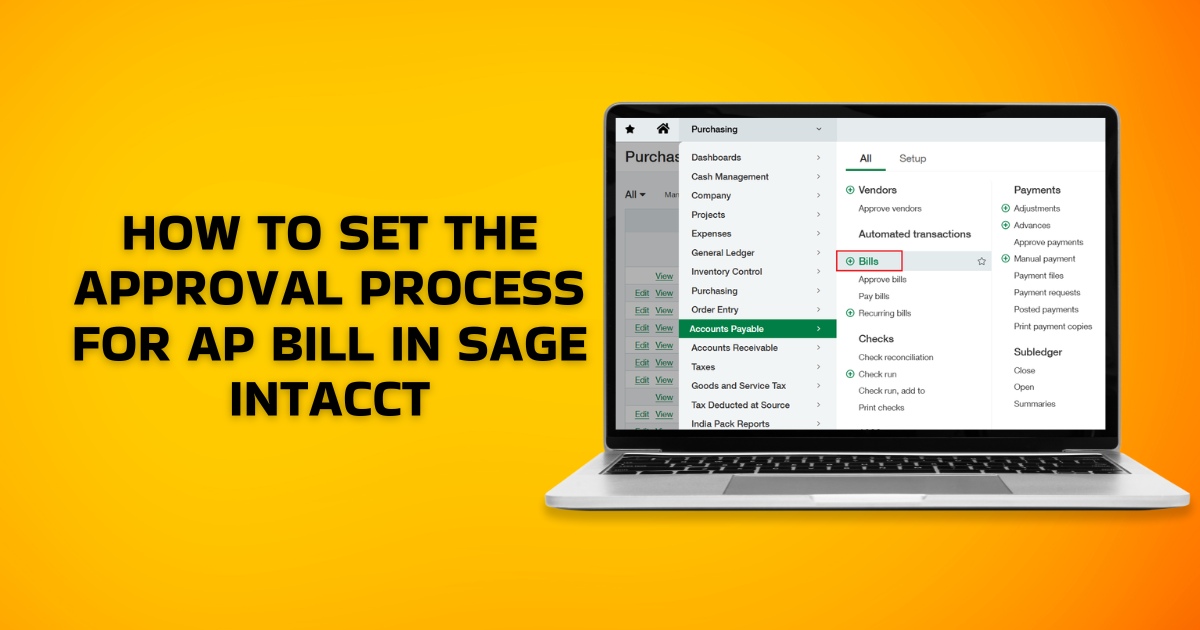

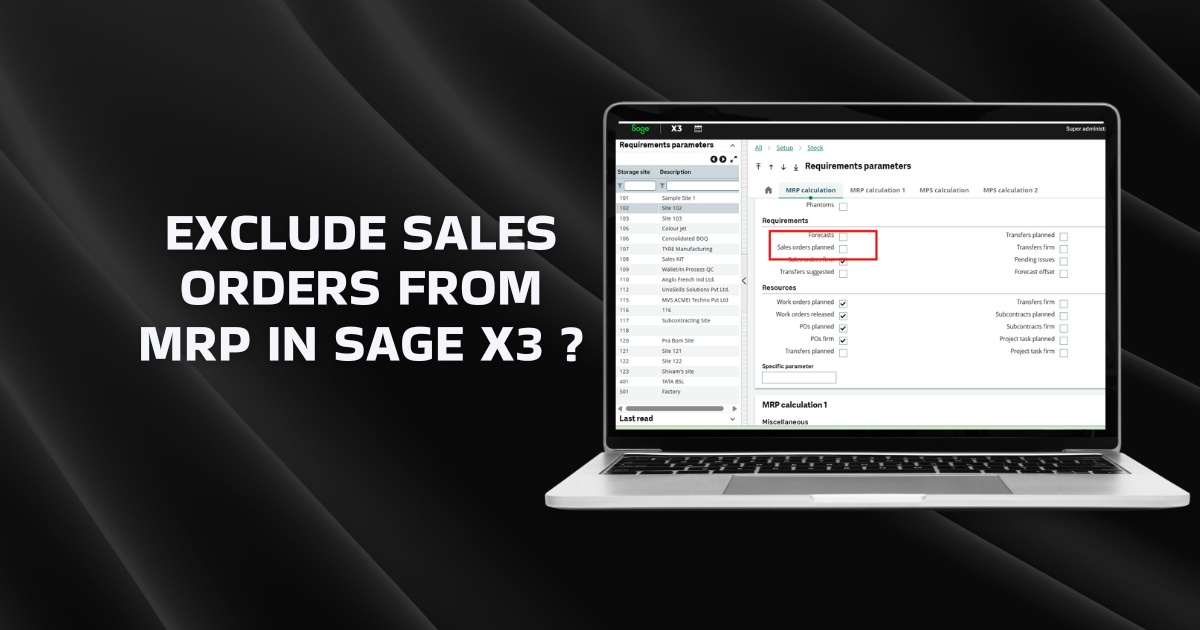

Sage X3 is a complete transformative solution that lets you manage your mobile sales force, and keep up with market demands through a robust inventory management system. It makes it easier to automate invoice creation, gain insights into your marketing performance, and align your activities with the preplanned budget.

FAQs

1. Why is Demand Planning and Forecasting So Important?

Planning forecasting holds significance for businesses for various reasons:

- Avoid under-estimating & over-estimating demand for your products

- Build effective pricing strategies to generate higher profits

- Build effective Inventory Replenishment strategies to quickly refill your stocks

- Maintain a minimum stock of inventory so that you don’t run out of storage

- Sell the right product at the right time at the right place

2. What is Collaborative Demand Planning and Forecasting?

Collaborative Demand Planning and Forecasting involves the usage of real-time market data, various technologies, and sophisticated algorithms between manufacturer and distributor (wholesalers and retailers) to accurately forecast the demand for the company’s products & services.

Collaborative Demand Forecasting in Supply Chain helps in various ways, viz.

- Use a collaborative approach to align organizational resources for better results

- Build collaborative strategies using various ERP modules to effectively manage sudden demand surges

- Synchronize your business strategies with other competitors so that you don’t miss out on new opportunities

- Implement proactive decision-making, reduce business risks, and focus on increasing profits.

- Make well-thought-of decisions to develop more realistic strategies.

3. Which Tools Facilitate Instant Demand Planning and Forecasting?

Demand Forecasting in Supply Chain is accomplished using various tools that enable businesses to anticipate demand uncertainties and proactively mitigate risks.

Here are some helpful tools:

- Spreadsheets: Businesses use spreadsheets to store & share data, collaborate in groups, and perform demand forecasting in Supply Chain.

- Legacy Tools: Traditional tools serve specific business functions. They are still used by many small and medium-sized companies with limited budgets.

- Sophisticated ERP Tools: A large number of businesses are turning to ERP Application to enhance the accuracy of the short & long-term demand forecasting in Supply Chain, generate demand insights, and reduce process cycle times.

4. What are the 3 Major Activities of Demand Planning?

Demand Prediction is a crucial process that primarily involves the following 3 major activities:

- Sales Forecasting: Let’s take a simple example of an Automotive ERP that makes sales estimations for monthly, quarterly & yearly periods, and helps you allocate organizational resources to capture new opportunities & minimize risks.

- Inventory Management: Regularly track your inventory. Avoid running out of stock and reduce excess inventory storage costs.

- Supply Chain Management: Make the right products available at the right place at the right time, reduce your shipment time & costs, and ensure on-time fulfillment of the customer’s products using Supply Chain Management Tools.

5. What is the Scope of Demand Planning?

Predicting demand involves a multitude of processes. Here are some of the important ones:

- Understanding the forces driving the demand for your products & services

- Analyzing historical sales data to discover new trends & patterns, seasonal fluctuations

- Analyzing real-world market challenges

- Constantly engage with the marketing, sales, production, and inventory teams

- Extract valuable insights from distributors (wholesalers and retailers)