What is Days Sales Of Inventory (DSI)?

Days Sales of Inventory (DSI) is a ratio that demonstrates how long it takes a company to convert its inventory into sales and gain a complete understanding of the health of the inventory.

Investors use ERP Software to calculate the Days Sales of Inventory and find out how efficiently it manages its inventory & cash conversion cycle and fulfills the demand for its products.

Days Sales in Inventory Formula

Now, let’s find out how to calculate the DSI using the Days Sales in Inventory formula. Nevertheless, you can also automate various inventory-specific operations & evaluate inventory performance using an Inventory Management System.

Days Sales of Inventory (DSI) = Average Inventory / Cost Of Goods Sold (COGS) * Period in Days

Let’s break down the our DSI formula:

- Average Inventory: This represents the sum of both the opening and closing inventories divided by 2.

- Cost Of Goods Sold (COGS): This represents the direct cost of producing your goods. For example, direct labor, materials used for the production, and production labor, among others.

- Period in Days: This indicates the duration in days (such as 30 days, 60 days, 90 days, etc.)

Examples of Days Sales Of Inventory

Now that we’ve already discussed the Days Sales in Inventory formula, let’s take a hypothetical example of a company ABC Ltd.

ABC Ltd. is a manufacturing company based in New Delhi. The average inventory of ABC Ltd during the financial year 2023-24 was Rs. 20,000, and the Cost of Goods Sold (COGS) was Rs. 4,00,000.

Now, let’s calculate Day Sales in Inventory.

DSI = 20,000 / 4,00,000 * 365 = 18.25 Days

The DSL in our case is 18.25. It indicates that the company will take 18.25 days to turn its stocks into sales. The company is able to sell its products on a frequent basis, and has a loyal customer base.

Difference Between High & Low DSI

Now, let’s find out the difference between companies with higher and lower DSI.

| High DSI | Low DSI | |

| What Does It Indicate? | Indicates the company is taking a longer time to sell its stock. | Indicates the company is taking a shorter time to sell its stock. |

| Inventory Management Efficiency | Possibly over-stocking or non-efficiency in inventory management | The company is managing its inventory very well |

| Impact on Inventory | Negative impact on the company’s cash flow as higher capital is tied up | Positive impact on the company’s cash flow as the company can use the capital for other investments/ projects |

| Investor Perception | Higher DSI may denote inefficiency at the operational level and supply chain | Lower DSI may denote operational excellence and greater agility in the supply chain. |

| Risk of Stock Obsolescence | Higher risk of stock obsolescence | Lower risk of stock obsolescence |

| Example Industries | Luxury goods, heavy machinery, and aerospace | Food, retail, e-commerce, and logistics |

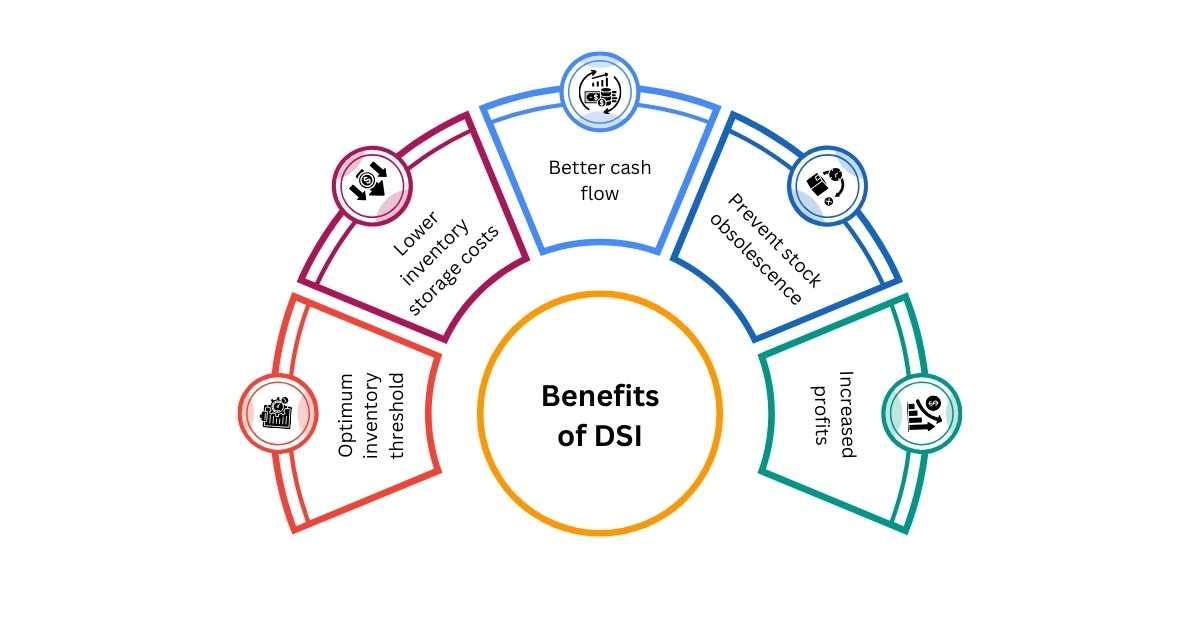

Benefits of Calculating the Days Sales of Inventory

DSI is an important metric that helps businesses manage their inventory in a better way, and improve their sales & profitability. Here are its key benefits:

1. Optimum Inventory Threshold

With too little stock in hand, your business can lose potential revenue-generating opportunities. In contrast, excess stock can tie up your business capital and you may experience a cash crunch. Always aim to keep a lower DSI.

2. Lower Inventory Storage Costs

With more inventory in hand, your business will incur higher inventory storage costs, insurance premiums, labor costs, and utility bills (such as electricity). You can reduce these costs by keeping a lower DSI.

3. Better Cash Flow

With less capital tied up to your inventory, you will have more cash in hand and a stronger Cash Flow Statement. You can invest this cash into new projects, and investments, and make better use of it for revenue generation.

4. Prevent Stock Obsolescence

Companies selling perishable items (such as dairy products, foods, ready-to-eat meals, and refrigerated grocery items) have to invest in building infrastructure for food safety, integrity & longevity. They face the risk of stock obsolescence should they fail to sell their stock before the expiry date. This necessitates the need to maintain a lower DSI.

5. Increased Profits

Higher DSI translates into lower sales and reduced profits. In contrast, lower DSI indicates rapid turnovers, leading to increased revenue. Your business should strive to reduce the DSI, i.e. clear off your inventory in a shorter duration, using a dedicated Sales Management System.

Limitations of Days Sales of Inventory

While DSI is a useful concept, it has certain limitations.

1. Varies Industry-wise

DSI varies from industry-to-industry. Some industries such as defense inherently have a very higher DSI. This may not be the case with the retail industry.

2. Temporary Seasonal Fluctuations

During Diwali, there may be a spike in the sale of TVs, refrigerators, and other electronic products. Such a temporary surge, along with the impact of other factors such as Elasticity of Demand, may not reflect the true nature of the DSI.

3. Risk of Miscounting

There is a risk of human errors and miscounting of the inventory, leading to incorrect DSI. Thankfully, you can avoid such errors using the highly-efficient Best ERP Software in India.

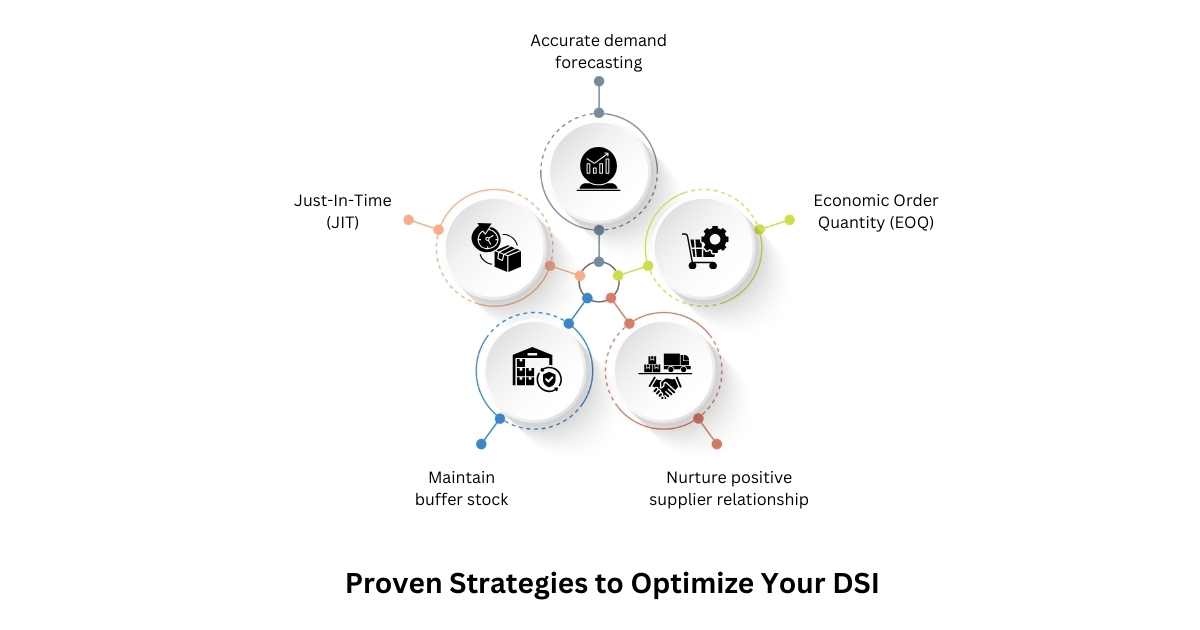

Proven Strategies to Optimize Your DSI

Let’s deep dive into some of the strategies to optimize your DSI, and improve cash flow & profitability.

1. Accurate Demand Forecasting

Leverage Business Intelligence Tools to make timely & accurate predictions about future demand for your products, and accordingly plan your production activity.

2. Just-In-Time (JIT)

Just-in-Time (JIT) models are part of the Lean Manufacturing concept. Adopting JIT can help you reduce your business disruptions and ensure adequate stock levels. They are a great way to minimize inventory wastage and improve your DSI.

3. Maintain Buffer Stock

Always maintain a buffer stock of inventory to meet sudden demand surges and fulfill customer expectations. An ERP Application can be a great help here from Material Requirements Planning (MRP) to automating minimum threshold management.

4. Nurture Positive Supplier Relationship

Develop and nurture strong relationships with your suppliers with Supply Chain Management Tools in ERP. Maintaining strong supplier relationships will ensure continuity in the raw materials, and minimal disruptions in the production activity.

5. Economic Order Quantity (EOQ)

The Economic Order Quantity (EOQ) technique involves reducing the cost of inventory holding and stockouts. It helps make informed decisions pertaining to inventory management and improving inventory efficiency.

Days Sales of Inventory (DSI) Across Different Industries

The DSI typically varies from industry to industry, and even between companies operating in the same industry. Here are some examples:

| Industry | DSI |

| Manufacturing Industry (Simple Products) | Lower |

| Manufacturing Industry (Heavy & Specialized Components) | Higher |

| Chemical Industry | Higher |

| Pharma Industry | Higher |

| Retail & Wholesale Industry (FMCG Products) | Lower |

| Retail & Wholesale Industry (Luxury Products) | Higher |

| Furniture Industry (Luxury products) | Higher |

1. Manufacturing Industry

Manufacturing companies selling simple products such as readily available materials, may have lower DSI. Manufacturing companies producing heavy & specialized components, typically have higher DSI. They may use a Manufacturing ERP to enhance inventory efficiency and improve their DSI.

2. Chemical Industry

Companies engaged in the manufacturing of complex chemicals on a larger production scale can have higher inventory levels, thus moderate to higher DSI. ERP for Chemical Industry is widely used to optimize inventory levels, bring supply chain efficiency, and ensure continuity in business profits.

3. Pharmaceutical Industry

Pharmaceutical companies tend to have a higher DSI because of different factors such as complex manufacturing processes, longer shelf life of their products, and uncertainty in the demand for their products. If you’re a pharmaceutical business, your best bet is to use Pharma ERP Software to minimize storage costs and prevent the risk of missed sales orders.

4. Retail & Wholesale Industry

Retail & wholesale companies engaged in the sale of FMCG products may have a higher inventory turnover and, thus lower DSI. Retail & wholesale companies engaged in the sale of luxury products such as jewelry, home furnishings, and electronic appliances, have a higher DSI. Retail ERP provides an extensive feature-set to tackle various problems faced by retailers. For example: First-In-First-Out (FIFO method), and Last-In-Last-Out (LIFO method) to clear off your inventory based on your strategic objectives.

5. Furniture Industry

The DSI of products in the furniture industry depends on the nature of the product. For example, if a company is engaged in the sale of luxurious furniture due to longer sale efforts, it will have a higher DSI, and vice versa. An increasing number of furniture companies are turning to an ERP for Furniture Manufacturing to lower their DSI and make strongly data-backed decisions.

Wrapping Up

Regularly calculating DSI will help you gain end-to-end visibility into inventory management, make informed to free-up your capital tied to excessive stock, improve inventory efficiency, and become agile to changing market needs.

If you’re planning to optimize your Days Sales of Inventory, fulfill your operational needs, and outshine your competitors, look no further than Sage X3. With this top-notch global business planning solution, gain access to a plethora of industry-specific modules, extensive customization options, and robust integration capabilities. fulfill your operational needs and outshine your competitors.

FAQs

1.What is Inventory Days Sales?

Days Sales of Inventory refers to the average number of days it takes for a company to convert its inventory into actual sales. It is an important measure used by executives, investors, and other external stakeholders to understand how the company’s products are selling vis a vis the inventory size.

2. How Often Should I Calculate Day Sales in Inventory?

You can calculate the DSI on a monthly, quarterly, or annual basis, as per your unique business and industry requirements. Tracking your DSI on a regular basis offers several benefits and future-proofs your business to changing market requirements.

3. What is Considered a Good DSI Ratio?

There is no “ideal DSI” for all the companies. In most cases, a lower DSI is always preferred. However, the DSI differs from industry to industry. Comparing the DSI of one company from one industry to another company in another industry would not be advisable. Instead, you should strive to compare your DSI with other companies in your own industry to find an ideal DSI ratio for greater inventory efficiency and profit maximization.

4. Why Do Investors & Creditors Calculate Day Sales in Inventory?

As we’ve seen in the what is Inventory Days Sales, the DSI is not just important for businesses, but also for investors. Here’s why:

- Sales Performance: Investors can get a glimpse of the company’s sales performance using the DSI.

- Liquidity Position: Both creditors and investors can evaluate the company’s liquidity position, i.e. its ability to meet the immediate financial obligations.

- Impact on Profit Margin: Companies with higher DSI may encounter more storage, rental, insurance, and other costs, leading to a reduction in the profit margin.

- Opportunity Cost: A company holding significant inventory may incur higher opportunity costs, and vice versa.

5. Is DSI the Same Thing as Inventory Turnover?

Days Sales of Inventory (DSI) and Inventory Turnover are often confused to be the same concept; however, they are not. DSI focuses on the amount of time it takes for businesses to convert their inventory into sales. The smaller the DSI, the better it is. In contrast, Inventory Turnover depicts the company’s ability to restock its entire inventory. Unlike DSI, a higher inventory turnover is usually preferred. Both DSI and Inventory Turnover are important business metrics.

6. What are the Benefits of Optimizing Both DSI & Inventory Turnover?

It’s a good business practice to optimize both the DSI and Inventory Turnover for increasing revenue and achieving higher profitability. Let’s discuss the benefits:

- Regularly calculating the DSI and Inventory Turnover Ratio will help you identify the room for improvement.

- Regularly track demand changes and uncover new opportunities to fulfill market expectations.

- Ensure faster clearance of your stock with various marketing & promotional offers and discounts.