What is Collaborative Planning, Forecasting, And Replenishment (CPFR)?

Collaborative Planning, Forecasting, And Replenishment (CPFR) is a collaborative concept that involves the integration of all supply chain partners, and the sharing of key business data between manufacturers & distributors (wholesalers & retailers) for seamless inventory planning, order fulfillment, and meeting market expectations.

Businesses across the world use ERP Software for collaborative planning, gaining supply chain visibility, forecasting their inventory levels, and building long-term strategies. It provides a centralized platform to simplify the collection and sharing of vital information to provide greater flexibility, reduce human errors, and avoid confusion.

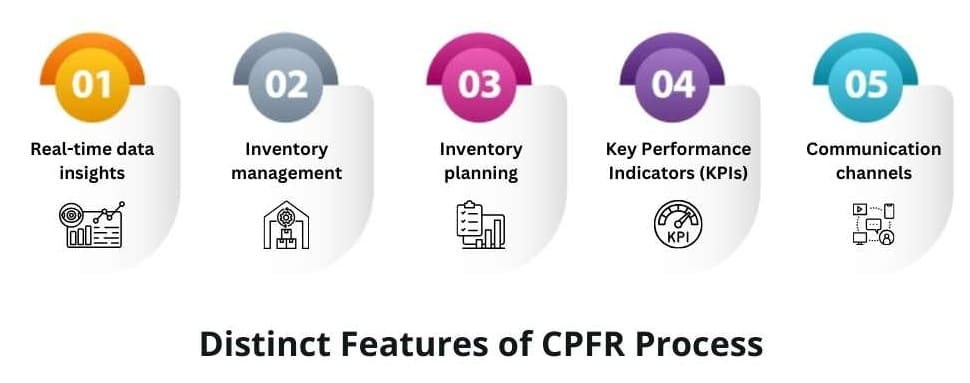

Distinct Features of Collaborative Planning, Forecasting, And Replenishment (CPFR)

It offers greater collaboration and data sharing and building long-term partnerships for mutual growth & success. Here are its distinct features:

1. Real-time Data Insights

It enables all stakeholders of the supply chain management to gain real-time insights into the important data for efficient planning & management of inventory, sales campaigns, and promotions.

2. Inventory Management

All the stakeholders benefit from a centralized Inventory Management System that provides deeper insights into various aspects of the inventory and helps them combat surplus stock, out-of-stock, and excessive storage costs.

3. Inventory Planning

All the stakeholders benefit from superior inventory planning and forecasting tools. The use of historical data and the latest market trends & patterns helps achieve its intended objectives.

4. Key Performance Indicators (KPIs)

Gain strategic & operational insights into the performance, measure target vs actuals, and track your inventory turnover & customer satisfaction using the Key Performance Indicators (KPIs).

5. Communication Channels

There is a constant need for communication to facilitate the transfer of information and the status of coordinated actions. Best ERP Software in India helps businesses proactively identify potential issues, and become responsive to market changes.

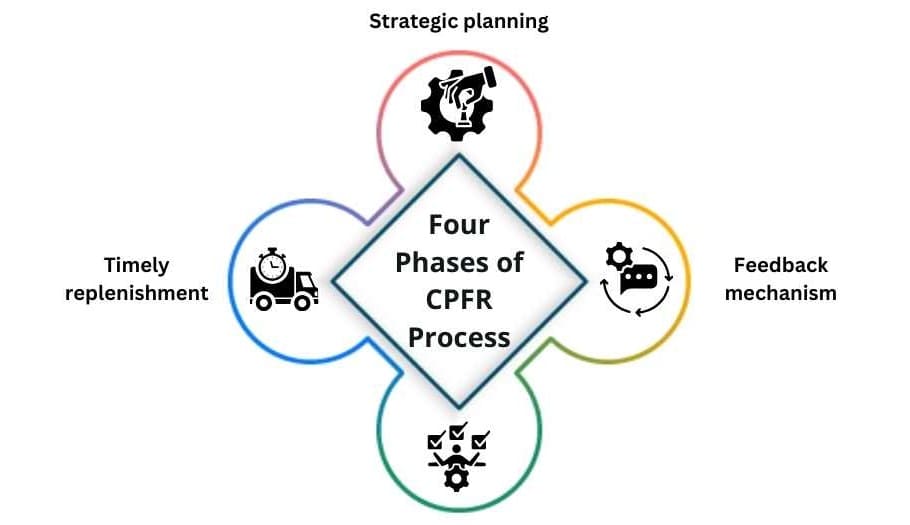

What are the Four Phases of the CPFR Process?

The process involves various collaborative activities intended to minimize inventory costs and become responsive to market changes. Here are the four phases involved in the process:

1. Strategic Planning

First things first, there is a need for thorough planning to ensure smooth collaboration between all the partners involved in the Collaborative Planning, Forecasting, And Replenishment (CPFR) process. This may involve scheduling regular meetings and assigning roles & responsibilities.

2. Timely Replenishment

Another phase is to ensure accurate planning and timely replenishment of orders. While doing so, you will need to accurately predict the demand for your products using powerful demand forecasting.

3. Project Execution

The next step is to execute the preplanned strategies and adhere to the initial plan. This involves various processes such as production, storage, dispatch, and customer order fulfillment.

4. Feedback Mechanism

Last but not least, a feedback mechanism should be deployed to understand the effectiveness of collaborative planning, forecasting, and replenishment (CPFR) and drive positive change in performance and efficiency.

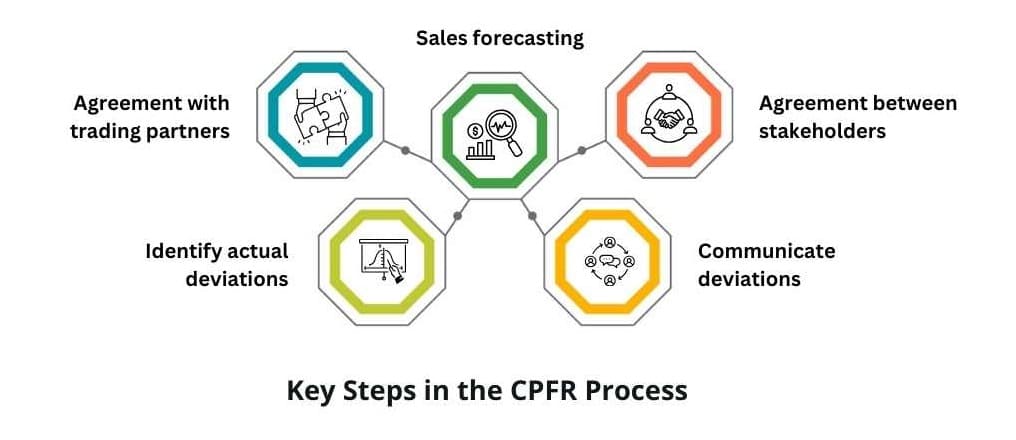

What are the Key Steps in the CPFR Process?

Here are the key steps that enable companies to plan and manage their activity accurately:

1. Agreement Between Stakeholders

Develop and formalize a comprehensive agreement for cooperation between different stakeholders involved in the supply chain process, viz. The manufacturer, and distributors (retailers & wholesalers).

2. Agreement with Trading Partners

Similarly, develop an agreement between all of your trading partners laying out specific details about data sharing. The idea is to work for a common goal and ensure long-term growth & success.

3. Sales Forecasting

Use Business Intelligence Tools to make timely & accurate predictions about potential sales. Anticipate demand for your products in the future, establish budgets, and allocate adequate resources to handle new spikes & seasonal fluctuations.

4. Identify Actual Deviations

Your sales forecasts need not be 100% accurate. There are always deviations in the forecasted sales and actual sales. Use a sophisticated Sales Management System to identify such deviations and improve the accuracy of your forecasts.

5. Communicate Deviations

Once deviations are found in the sales forecasts and actual sales, report them to all the stakeholders involved (manufacturers, wholesalers, and retailers). This is important for building trust and ensuring the flow of accurate information across all the concerned parties.

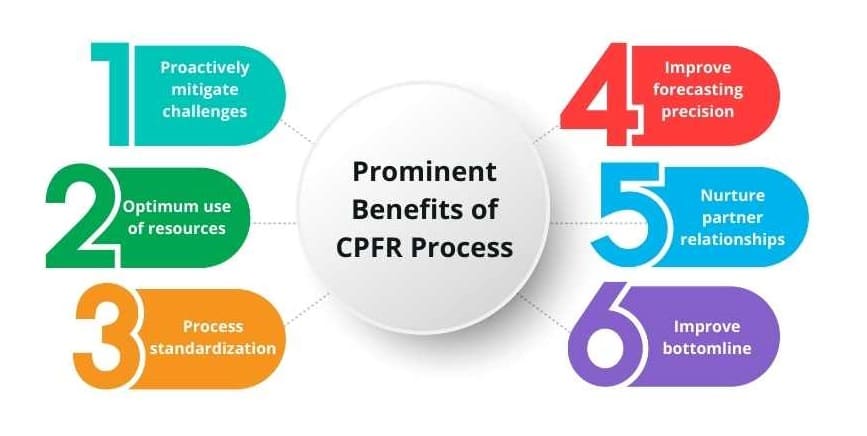

Prominent Benefits of the CPFR Process

It offers tremendous benefits from managing the company’s inventory and ensuring smoother procurement to optimizing the supply chain process.

1. Proactively Mitigate Challenges

It emphasizes proactive communication between different parties in the supply chain. This helps with the proactive identification of potential problems and the reduction of supply chain disruptions.

2. Improve Forecasting Precision

Compare targets vs actuals. Identify potential deviations in the supply chain network and quickly come up with resolutions to real-world challenges using dedicated Supply Chain Management Tools. Never run out of stock and make accurate forecasts pertaining to the inventory levels.

3. Optimum Use of Resources

Align all the supply chain processes including production, inventory management, and replenishment, with the actual demand for your products. Optimize your resources for the best possible use and minimize unnecessary costs & wastages.

4. Nurture Partner Relationships

Build trust and nurture strong, transparent & strategic relationships with your partners. Seamlessly collaborate with each other and scale your relationships to new highs for mutual growth & profit maximization.

5. Process Standardization

With process standardization, provide a consistent experience to your customers at all levels, minimize potential errors, and ensure efficiency across all the stages of the supply chain.

6. Improve Bottom line

The bottom line refers to the net income reported in a company’s Income Statement. Improve your bottom line, and reduce the cost of capital & operational expenditures for higher growth & profitability.

Limitations of the CPFR

While it is a useful collaboration strategy, it has certain limitations too.

1. Data Reliability

Inaccurate, incomplete, or obsolete data can pose a challenge to achieving the true intended objectives of the deployment.

2. Collaborative Planning

There is a constant need for active collaboration between all the trading partners. Otherwise, the business risks disrupting the entire process.

3. Deployment Complexities

Its deployment across large organizations can be time-consuming. It can be a resource-intensive process, requiring close cooperation across different teams.

4. Employee Resistance to Change

Some employees may be resistant to change. They may be reluctant to the idea of adopting new transformative changes.

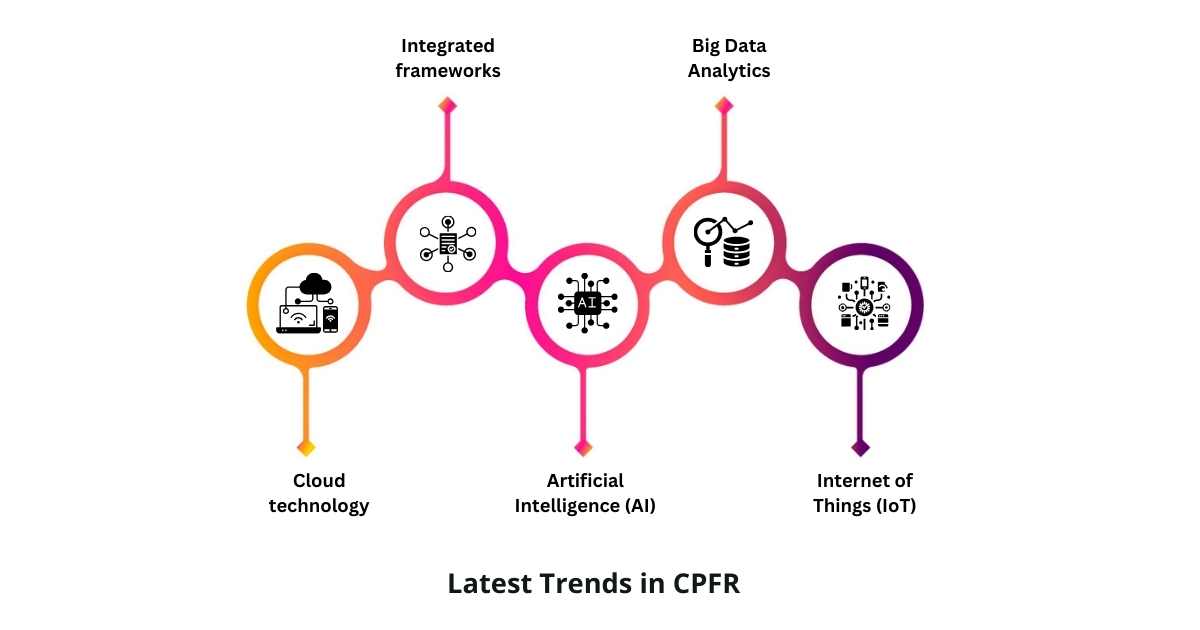

Latest Trends in the CPFR

Now, let’s have a look at some of the most recent trends in the CPFR activity:

1. Integrated Frameworks

The emergence of various integrated frameworks has helped different stakeholders such as manufacturers, wholesalers, and retailers, to collaborate in the real-time, forecast, and replenish the inventory levels.

2. Big Data Analytics

With the use of Business Management Software, businesses can accurately find new trends & patterns, and convert large & complex data into small actionable insights for powerful decision-making.

3. Cloud Technology

Cloud ERP has increasingly benefited businesses in various ways from remote accessibility, flexibility, and customizability to reduced costs. Businesses are relying on cost-cutting cloud solutions to gain a competitive advantage and improve efficiency & accuracy.

4. Artificial Intelligence (AI)

The use of Machine Learning (ML) and Artificial Intelligence (AI) has enabled businesses to achieve faster responsiveness, real-time data analysis, and highly data-driven decision-making.

5. Internet of Things (IoT)

Internet of Things (IoT) devices revolutionize the process and help businesses meet consumer expectations for speed & efficiency. Automatically track the speed & position of the vehicles, and get maintenance notifications, and adapt to changing consumer requirements.

Wrap Up

Collaborative planning, forecasting, and replenishment (CPFR) provide better visibility and collaboration across different supply chain partners. It helps develop contingency plans and a resilient supply chain network. It works by developing an agreement between the supply chain partners with definite conditions to achieve a common goal.

Sage X3 is your key to the next-level planning. Unlock the door for increased inventory efficiency & cooperation between different supply chain partners. Combine the strength of all the partners to build a more resilient supply chain network and align your inventory strategies with the ever-changing market expectations.

FAQs

1. What is the CPFR Full Form?

The CPFR full form is Collaborative Planning, Forecasting, And Replenishment (CPFR). It is a process that promotes cooperation among different stakeholders of the supply chain process, including manufacturers, wholesalers, and retailers to efficiently meet customer demands.

2. What are the Strategies of CPFR?

Companies can adopt various strategies as part of the process. Here are some of the most common ones:

- Vendor Managed Inventory (VMI): In this type, the vendor is responsible for monitoring and replenishing the inventory as per the pre-agreed conditions using an Online Procurement Management System.

- Just-in-Time (JIT) Inventory: This strategy orders inventory as and only when it is required for production activity or fulfilling customer demands.

- Cross-docking: Reduce the time taken for shipment of the products from distributor to final consumer and reduce inventory tracking, handling & transportation costs.

- Strategic Partnerships: Build and nurture long-term strategic partnerships and collaborations between different partners.

3. How is CPFR Different from Traditional Supply Chain Management Practices?

The primary difference between CPFR and traditional supply chain management practices is that the former focuses on all aspects of the supply chain and ensures collaboration between all the stakeholders (such as manufacturers, wholesalers, retailers, etc.). In contrast, the latter focuses only on specific aspects of the process and lacks collaboration between different stakeholders involved.

4. DoesCPFR Support All Industries?

Yes, it supports all the industries. It is significantly adopted in the consumer goods and food & beverages industries. FMCG companies across India use the ERP for food industry to tackle modern-day challenges, minimize costs, and increase efficiency in their activities.

5. How Can Businesses Overcome Challenges in CPFR?

There are several ways your business can overcome the challenges faced in its deployment:

- Sharing of Business Data: Companies are hesitant to share business data with external stakeholders, and rightly so. Building a network of trusted & transparent partners can be helpful.

- Technical Challenges: Deploying a full-fledged traditional ERP Application may require training and specialized expertise. You can overcome this challenge through cloud-based ready-to-go ERPs.

- Demographic Challenges: In today’s era, it’s common for manufacturers to operate in multiple countries. Language and cultural differences between the manufacturers and distributors can be mitigated through mutual respect.

- Access to Up-to-date Information: Sharing data between multiple entities simultaneously can be a challenging task. You can mitigate the risk of obsolete or inaccurate data through an ERP implementation.

6. How Does CPFR Empower Different Industries in India?

Here’s the breakdown of its industry-wise usefulness:

- Fast-Moving Consumer Goods (FMCG): FMCG companies widely adopt it to enhance customer service levels, improve cash flow, and improve order forecasting accuracy.

- Manufacturing Companies: Perform real-time performance assessment, and ensure your products are available in the market at the right time with a Manufacturing ERP.

- Retail Outlets: Retail ERP enables retailers to capture and store inventory-specific information, and benefit from a highly-efficient demand forecasting & streamlined procurement process.

- Pharmaceutical Companies: Pharma ERP Software lets pharmaceutical companies prevent the shortage of critical drugs & ensure smooth supply chain operations.

- Automotive Companies: Automotive ERP is used to coordinate supply chain operations, forecast demand for products, and meet customer expectations.