What is AI in the Food Industry?

AI in food industry is the use of artificial intelligence technology and robotics to set new standards of efficiency across the food supply chain and production, such as driving innovation in new product development, improving food quality and safety and streamlining food sourcing.

Artificial intelligence (AI) is fast gaining popularity in the food business due to its superhuman ability to analyze vast amounts of data using ERP for food industry and smartly predict demand and deliver fresh insights to improve recipe formulations, reduce production costs and minimize food waste.

Applications of AI in the Food Industry

Today, consumers are more educated and aware and seek more transparency in food sourcing and preparation. Health-conscious consumers are increasingly looking for diverse food products. Moreover, sustainability and climate change have become buzzwords, which demand food manufacturing companies to step up their efforts to minimize emissions and achieve climate goals.

AI is witnessing rapid growth in India, growing at a CAGR of 25 to 35%, with its market size expected to touch $17 billion by 2027. The combination of AI and food is fueling transformational growth in the food sector as the scope of AI technology integrated with ERP software extends far and wide. Let’s take a look at the various ways in which the food processing industry is integrating AI in its operations.

1. Agricultural Productivity

Farmers are acutely monitoring crop health data, tracking weather patterns, and taking proactive measures to improve agricultural yield. For instance, using real-time data, they can now control temperature and light levels in smart greenhouses. To minimize the impact of pest attacks on crops, farmers can analyze thermal imagery using satellite data.

2. Product Innovation

AI can analyze vast culinary databases using an ERP system to personalize recipes for different taste buds and food cultures. It provides innovative suggestions on healthy ingredient combinations and suggests ways to blend flavors, marking a fundamental shift from traditional research and development mechanisms, and helping save time.

3. Food Manufacturing

Artificial intelligence in food processing and manufacturing assists with food production planning and scheduling of production lines. Through ERP implementation, manufacturers can leverage real-time data analytics to predict equipment failure and avoid production downtime. Besides, food AI can trace contaminants in food production, ensuring quality control and food safety compliance.

4. Food Sorting

Utilizing the power of deep learning, AI in food technology is being used during sorting and grading processes on the food assembly line. For example, food processors can sort fruits based on their size, minimizing manual intervention. Using AI and inventory management software, unwanted raw material can be easily detected, ensuring accuracy and precision in ingredient selection.

5. Food Packaging

It’s remarkable how smart packaging technology is changing the way food is packed. Going beyond the usual flexible packaging, smart packaging helps track temperature and humidity, ensuring quality control of food and extending its shelf life. AI in food technology also aids in packaging material selection and size based on food type.

6. Food Delivery

The application of AI in food industry has enhanced the capabilities of the food delivery process, benefiting food manufacturers, logistics service providers and customers alike. By integrating AI algorithms in the supply chain management software, you can analyze real-time traffic patterns, delivery location and driver and vehicle availability, thus reducing delivery cost and time.

7. Food Retail

The use of AI in food retail assists with forecasting customer demand based on historical data and seasonal variations, a powerful feature found in some of the best ERP software in India. Consequently, retailers can plan procurement and dynamically manage product offerings. This considerably increases the inventory turnover ratio and ensures effective utilization of shelf space.

8. Food Recall Management

Considering the sensitive nature of food, it is not uncommon for food processing companies to recall affected product batches from the market. By tracking real-time data using food AI, food processors can manage product recalls with greater accuracy and cost-effectively. Further, AI-powered food ERP reduces recall instances through enhanced food safety and batch traceability.

9. Sustainability Efforts

AI in food processing is responsible for driving sustainability initiatives of the food business in ways unimaginable before. By focusing on resource efficiency, AI is enabling better water and energy consumption. Through enhanced food production and resource management, organizations are using AI to reduce waste and follow eco-friendly and efficient practices.

Examples of AI in the Food Industry

Let’s talk about a couple of real-world examples to get a sense of how leading innovators in the food industry are using AI in unexplored areas and generating unparalleled benefits for stakeholders.

ITC has deployed advanced AI-enabled models that can predict possible disruptions in the agri-value chain. These AI models perform climate risk modelling, which helps them forecast the risks across 140 sites and take risk mitigation measures. Today, AI helps ITC group these sites based on heat, stress and temperature and design tailored solutions for each.

Mukunda Foods, an automation solution provider to cloud kitchens, is redefining food preparation in India. By incorporating a range of advanced technology systems like AI, IoT, Image Analytics, Assistive Cooking Technology and centralized cloud computing powered by cloud ERP systems, the company has manufactured various cooking machines that can accurately prepare global cuisines.

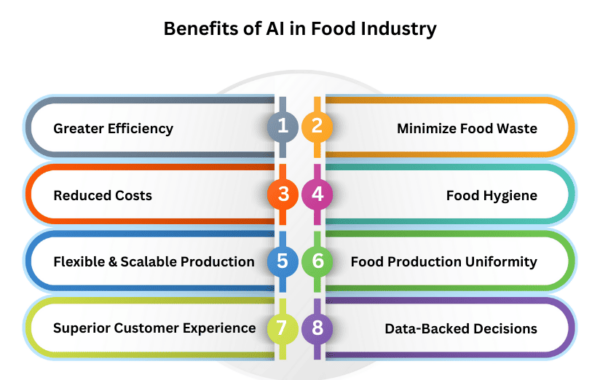

What are the Benefits of AI in the Food Industry?

Blending AI and food derives several benefits for the food industry, reshaping how food companies approach challenges. Here are some of the key benefits of AI in the food business.

1. Greater Efficiency

Be it analyzing market trends to optimize procurement strategies or using AI-powered robots and ERP functions to automate repetitive food production tasks, the implementation of artificial intelligence in food processing industries is enhancing efficiency at every stage of the supply chain.

2. Minimize Food Waste

Perishable food items such as dairy and meat are always at the risk of getting spoiled and need effective inventory management methods such as FIFO. By integrating AI with IoT sensors, you can track the shelf life of every ingredient and make smarter decisions to reduce food waste and spoilage.

3. Reduced Costs

AI-enabled demand forecasting model and inventory management system offer actionable insights on what to produce and how much to produce, preventing overproduction. Besides, AI can help food companies optimize resource consumption through production optimization.

4. Food Hygiene

Maintaining excellent food hygiene is another area where AI in food technology is helping. Advanced data-driven models can detect microbial debris and food residue while ensuring meticulous equipment cleaning and allergen reporting.

5. Flexible & Scalable Production

AI models embedded within food ERP solutions can track real-time changes in demand from channel partners and suggest changes in food production line. Further, AI makes it simpler and faster to scale production in anticipation of rising demand.

6. Food Production Uniformity

Food quality, precision and consistency are the defining factors to build trust and brand reputation. With AI in the food supply chain management, it has become possible to enable smarter, quality-focused and more efficient production practices.

7. Superior Customer Experience

AI models can meet the specific dietary preferences of customers and enable smart product mix management. AI-driven chatbots integrated with ERP software can extract order details and reply to customer queries instantly and accurately, leading to higher customer satisfaction.

8. Data-Backed Decisions

AI has raised the bar in strategic decision-making with its ability to analyze big data in a matter of seconds. Whether it is analyzing equipment maintenance data powered by predictive analytics or navigating food challenges, AI ensures faster, data-driven responses.

What are the Challenges Facing AI in the Food Industry?

Although integrating food and AI unlocks tremendous benefits, the food industry is facing multiple challenges in accelerating the adoption of AI technologies.

1. Integration Constraints

Many companies don’t have the right solutions that can integrate with modern AI tools. And those that do have advanced food ERP systems may lack expert support and funds to adopt AI-driven systems.

2. Regulatory Compliance

Food companies must adhere to strict FSSAI regulations. Can AI adapt to changing regulations and different compliance requirements across jurisdictions? Errors in automation can lead to penalties.

3. Change Management

At times, the management is interested in implementing AI but the workforce is resistant to making a shift towards AI, fearing job loss. The lack of skilled personnel in managing AI is another obstacle.

4. Security Concerns

Does integrating AI models into existing software systems increases the risk of data breaches? Is customer data not safe? Data privacy and security concerns are real and need expert solutions.

5. Equipment Maintenance

Until the food industry can be sure of the use of AI in maintaining equipment, nobody would want to risk an expensive downtime. What if the AI responses are not in line with the actual equipment condition?

6. Process Flexibility

One of the concerns is regarding AI’s ability to manage flexibility in production and assembly lines. Will AI enhance the customization and responsiveness to changing order priorities?

7. Building Scalable Process

As the company grows, its requirements change. While the existing ERP software can scale up, the question remains whether the AI algorithms can scale to keep up with demand and complex processes.

8. Ethical Considerations

Using AI in the food industry can lead to biased decisions. The bias could be in the pricing of food products, supplier selection or even quality control, putting public health and food safety at risk.

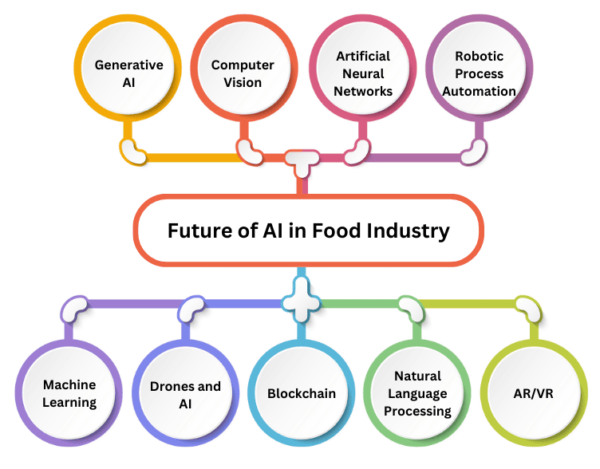

What is The Future of AI in the Food Industry?

Looking at the pace of technological innovation, the future of AI in food industry certainly looks promising. Let’s explore how various AI technologies can shape the future of the food business.

1. Generative AI

Analytical AI processes well-structured data to make predictions. Gen AI, on the other hand, has the ability to process large sets of unstructured data to generate new ideas. In agriculture, gen AI can create “what if” scenarios in the ERP software to predict how things might turn out based on weather patterns, soil conditions and pest levels.

2. Computer Vision

Computer vision is the ability of computers to see and interpret things, similar to human vision. In the food industry, computer vision can be easily integrated with your manufacturing ERP software to assess the ripeness of fruits and vegetables on the production line. It can also identify defective products, check labelling data on packaging and ensure precise quantity inside food packets.

3. Artificial Neural Networks

ANNs with interconnected nodes can learn patterns and make decisions, matching intelligence of human brain. These tools hold immense potential in food safety compliance and quality control. By creating AI algorithms of how different microbes grow under varied conditions, ANNs can help predict food safety risk.

4. Robotic Process Automation

Robotic process automation(RPA) simulates human actions to automate repetitive tasks and has wide applications in the food industry. Whichever ERP modules you use, RPA capabilities can be easily built-in, such as AP automation streamlines supplier management by enabling auto-comparison of prices and generating purchase orders.

5. Machine Learning

Machine learning, where computers learn from data and improve their performance, is one of the most significant AI technologies making its presence felt in the food industry. Advanced ERP system uses ML algorithms that can analyze customer feedback and data from IoT sensors on food production machines to identify areas for improvement.

6. Drones and AI

AI-driven drones use aerial data and intelligent insights to monitor crop health by identifying moisture levels, thereby minimizing manual inspections. Drones integrated with warehouse management system can monitor food inventory levels in large warehouses, reducing food waste. AI-guided spraying can optimize fertilizer consumption, spraying only where needed.

7. Blockchain

Blockchain is a breakthrough technology that records transactions in a network of computers to ensure that data can’t be manipulated. Blockchain helps maintain data transparency from food sourcing to production and delivery. During product recalls, food can be easily tracked to its source. Further, it facilitates secure and automated payments between suppliers and food producers.

You Might Also Like: How Product Recall plays a vital role in the F&B Industry?

8. Natural Language Processing

Natural language processing is a field of AI that combines artificial intelligence and linguistics. By processing customer feedback data that exists on your ERP system, NLP models can analyze customer sentiment. NLP can also be used for menu analysis for product development, allowing food manufacturers to analyze menus and ingredients in different languages.

9. AR/VR

Augmented Reality(AR) technology projects a digital view of things to understand how they appear before they exist. It is commonly used during prototyping, such as a food distributor looking for new products may ask you to show how the product will look before you begin production.

Similarly, Virtual Reality (VR), often used with VR headsets, can help you to create a simulated environment for customers, allowing them to engage with the product digitally. It can also be used to train staff on food safety protocols in a risk-free digital environment before they begin production.

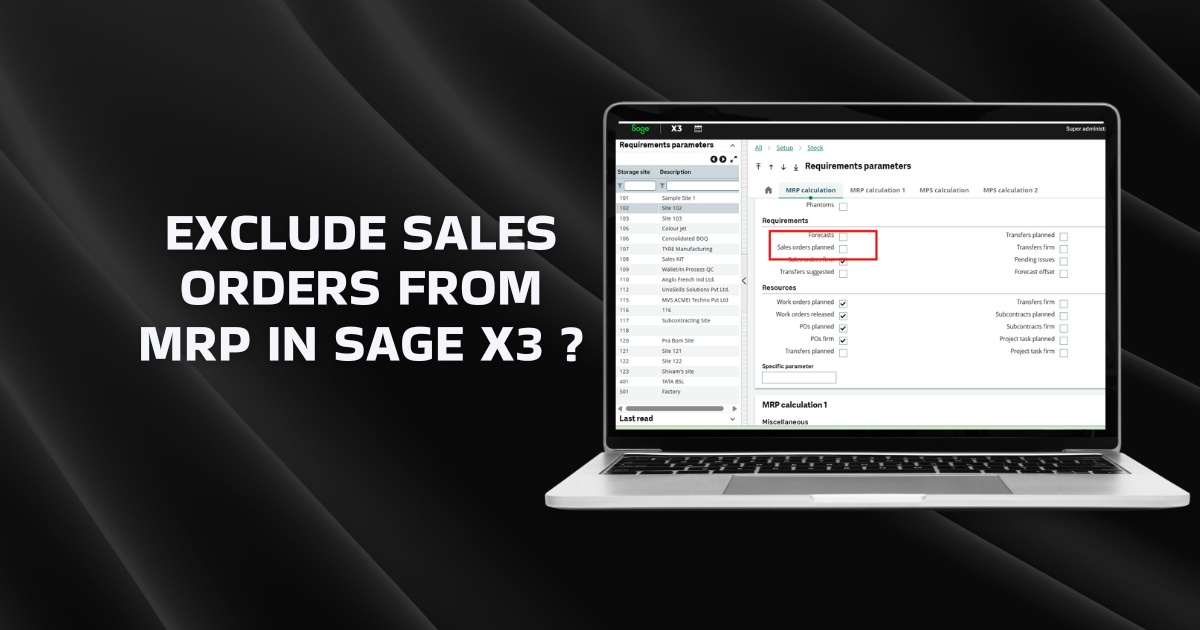

Lead the Food Industry with AI-powered Capabilities

AI algorithms have become an integral part of the food industry, revolutionizing the traditional approach to food supply chain management. As food processing companies scale their operations using food ERP, artificial intelligence is set to take center stage, helping you gain a competitive edge with precise data-backed decisions.

With intelligent and efficient ERP software like Sage X3, you can integrate all of the AI-driven technologies to shape the future of your food operations. Be it procurement, production, R&D or inventory, Sage X3 has all it takes to set new standards of business excellence, enhance customer experience and reduce production costs.

FAQ

1. What Is Meaning of AI In The Food Industry?

AI in the food industry utilizes automation and robotics technology to improve processes like procurement, manufacturing, quality control and customer service.

2. Can I Use AI To Improve Food Quality?

Yes, you can. Leading food companies are already using AI to monitor factors such as flavor, texture and freshness, to maintain consistent food quality.

3. How Does AI Help In Food Safety?

Artificial intelligence can detect potential food safety issues by analyzing vast amount of data on storage, temperature and hygiene to prevent contamination and spoilage.

4. What Is The Role Of AI In Food Delivery?

Artificial intelligence can analyze real-time traffic pattern, optimize delivery routes and track driver and vehicle availability, thereby reducing logistics cost and save time.

5. Is AI Implementation Costly For Food Companies?

The cost depends on what capabilities you want to build and what problems you want to solve. Nonetheless, AI technologies when integrated with food ERP software improves efficiency, reduces waste and increases profitability.