Manufacturing is a huge contributing factor to the country’s economy. The industrial revolution resulted in mass production and repetitive processing of goods with the use of vast mechanisms that even help to lower costs and increase profitability. The manufacturing sector has undergone humungous change, from manufacturing man-made goods to leveraging technology and machines to produce goods. It engages in the making of finished products after undergoing multiple stages of the manufacturing process.

The Manufacturing Industry is more diverse in this era with different types of industries such as the automotive sector, Pharmaceuticals, food and beverage industry, apparel manufacturing, wood product manufacturing, etc.

What is the Manufacturing process?

The manufacturing process is a complex task which involves the production of finished goods which consumers can use safely. In simpler terms, the manufacturing process refers to a production method, or approach a business implements to make its products. The production process begins with the sourcing of raw materials and ends with making a finished product. And quality control is a significant aspect of the manufacturing process.

Advanced manufacturing techniques make use of high-tech machinery, raw materials, technology and labour to complete the production process. The ultimate goal of the manufacturing process is to create quality goods at an affordable price, in large quantities, minimize waste and ultimately increase the revenue of the business.

A business selects the production process depending on customer demand, sales forecasts, manufacturing costs, the assembly technique, available raw materials and resources.

For example, if you have particular raw material in bulk and you use it to make finished goods in bulk or produce smaller batches to fulfill the customer orders without spending money on additional storage.

Also Read :10 Manufacturing ERP Modules You should look for in an ERP System

Steps of the Manufacturing Process

So before understanding the types of manufacturing processes, it is vital to know the steps or the stages of the manufacturing process for certain manufacturing processes and industries.

⇒Create a product vision

It is vital to have a product vision, brainstorm with your team and develop a vision as it is the seed that will grow into a successful product. Understand your target audience, market size, the demand for the product, competitors, trends, funding requirements, and product roadmap.

⇒Research your product niche

Before investing in the vision, research and gather insights about your niche. Find information on how you can make your custom product stand out, or if you prefer contract manufacturing and the different ways to market your product.

⇒Design the product

In this stage, keep the end user’s needs in mind and design the product. Analyse the resources required, the lifespan of the good, accessories and the function of the product.

⇒Finalise the design

After figuring out all the answers in the earlier step, finalise the design of your product. Create a bill of materials for all the resources which you will be using for the manufacturing process or working prototype.

⇒Test the prototype

In this stage, test the product and examine if it will serve the customer demand. In this stage find all the issues with the design and solve them.

⇒Manufacture the product

Develop a manufacturing plan comprising the details of raw materials, parts, components and the stages of the assembly process.

⇒Get reviews and do more testing

Before launching the product in the marketplace, do more testing and get feedback. This avoids failures.

⇒Launch the product

After finishing all the above stages, start with the marketing campaigns and launch the product.

Also Read : How is ERP Systems Manufacturing still helpful for Small Businesses?

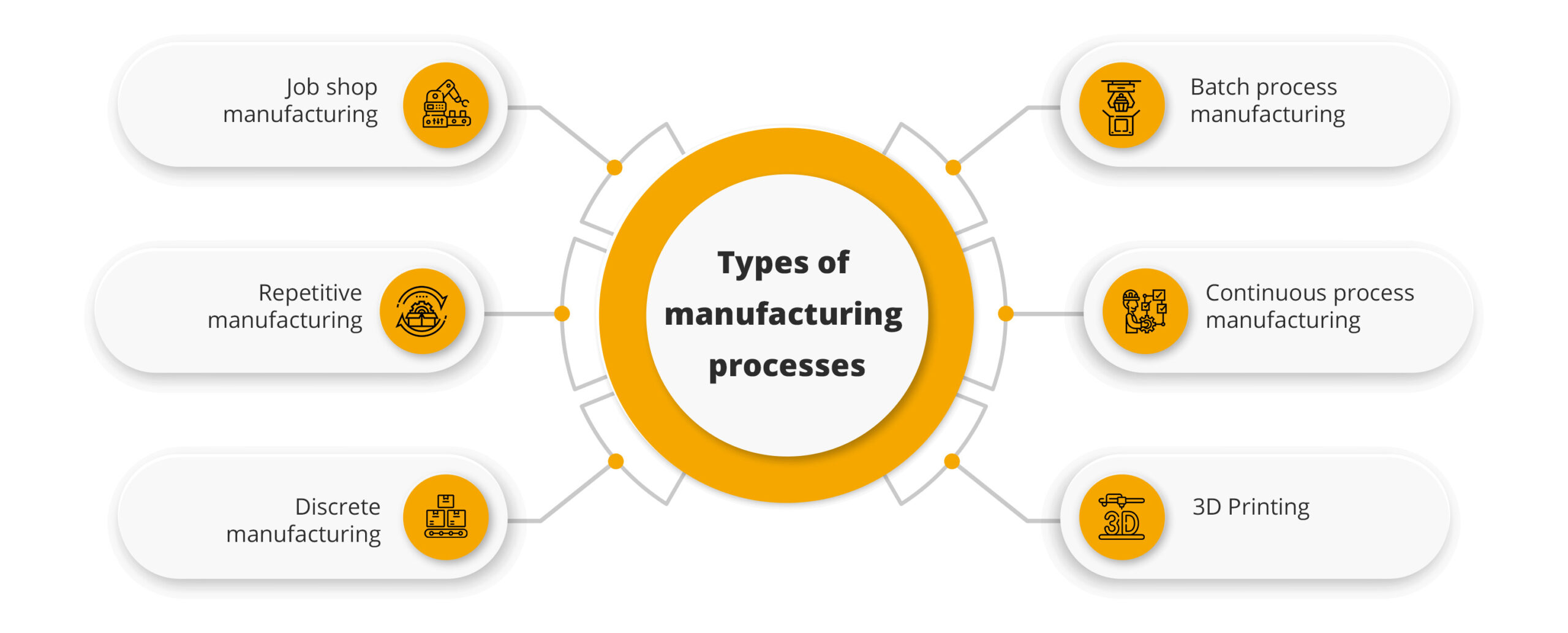

Six types of Manufacturing processes

There are multiple manufacturing processes and different approaches to produce a product. It is up to the company to choose the type that suits them as one manufacturing approach doesn’t suit all types of companies.

⇒Job shop manufacturing

This manufacturing approach uses production areas such as workstations and workshops instead of production on endless assembly lines. Each worker has to add each part to the product as it reaches their workstation till the final product is finished. This approach is best suitable for custom manufacturing as it is a slower process. And it involves the production of low-volume goods which is highly customized.

For example, if a business builds a custom wardrobe. It goes to each workstation for different processes, one will be sawing the lumber, another will be applying resin, another will be designing it, one will be polishing varnish etc. The process continues till the product is completely done.

⇒Repetitive manufacturing

A manufacturer relies on repetitive manufacturing to repeat the same process on the assembly line. This approach continuously repeats the manufacturing process 24*7 for all similar products with faster operation speeds.

Some of the industries depending on repetitive manufacturing processes are electronics, automotive, semiconductor, durable consumer goods and many more.

These industries involve in the mass production of finished goods as the market demand for the product is consistent and predictable. And the assembly line of repetitive manufacturing remains almost the same with just a few changes.

The repetitive manufacturing process is applied to the manufacturing process of high-volume goods and sales-order-oriented sectors like the automotive industry. High-volume manufacturing machinery and robots can enhance throughput at an affordable rate in these manufacturing units.

⇒Discrete manufacturing

The discrete manufacturing process is similar to repetitive manufacturing as it uses the production line. But it undergoes frequent changes for diverse products. Each time when the products are switched, The configuration of the assembly lines has to be changed. So in the manufacturing units, it is known as a changeover. In addition, the change of set will cost in terms of labour and resources.

In discrete manufacturing, especially for products like computers and laptops, frequent customizations require adaptable assembly lines. ERP for electronics manufacturing efficiently manages these changes, ensuring production agility while upholding quality standards and meeting consumer demands.

⇒Batch process manufacturing

This type of manufacturing process is similar to the job shop manufacturing process and discrete manufacturing. One batch of finished goods will be sufficient to meet customer demands. After the manufacturing process, the equipment is cleaned and left idle till the next batch is prepared.

Some examples of batch processes in manufacturing are newspaper printing, food production, pharmaceuticals and many more.

⇒Continuous process manufacturing

Continuous process manufacturing and repetitive manufacturing are similar in this aspect, it runs 24*7 and it involves in the production of large quantity products. The only difference is the products used for manufacturing. It uses raw materials like gases, powders, slurries and liquids instead of solid constituents.

Some of the industries using continuous process manufacturing are pharmaceuticals, power stations, chemicals, fertilizers and furnace(steel and iron).

⇒3D Printing

Industries earlier recognised five manufacturing processes such as repetitive manufacturing, continuous manufacturing, batch manufacturing, job shop manufacturing, and discrete manufacturing. Currently, industries began recognising 3D printing as the sixth manufacturing process type.

3D printing is vastly used for the manufacturing of diverse products. It was developed in the year 1980s, it uses diverse materials and composites such as plastics, and metals to create 3 layered products. And it depends on a digital model, no mechanisation and labour are needed to manufacture this product.

Now this field has expanded tremendously with dozens of 3D printing manufacturers and thousands of products sold in the market. Some of the products which it manufactures are shoes, prosthetic limbs medical, dental devices and many more.

These are different types of manufacturing processes. Some other traditional manufacturing types are machining, joining, forming, and casting.

Choosing a Manufacturing Method

Industries are diverse and they have to rely on multiple manufacturing processes or dedicated production lines to successfully finish a product. One manufacturing process doesn’t fit all business types. So choosing a manufacturing technique depends on various factors discussed below :

- The raw materials usage

- Total budgeting

- The duration of each stage

- Product dimensions

- Product volume

- Available machinery and tools

- Wastage and dimensions of the goods.

Conclusion

The manufacturing industry is vast and a complex business sector. Manufacturing processes vary depending on the type of industry. Relying on any manufacturing software like an ERP system can ease the complex process and efficiently complete all the stages. Leveraging manufacturing systems will boost revenue, establish process control and helps in the growth of the business. It helps in staying relevant and competitive.