SUMMARY

For the next two decades, pharmaceutical manufacturing industries might completely reshape from inside and outside with the use of transformation and ingenious market shifts. However, the manufacturing plants will continue to generate new methods to produce more efficient ways of manufacturing medicines. To achieve consistent growth, the pharma industries might incorporate top-notch technologies including AI, Machine learning, Big Data that will surely help develop long-lasting and prominent manufacturing processes.

With the continuously increasing market pressures, the pharmaceutical manufacturing practices are seeking constant change and it has now become one of the industries that usually lag in terms of technical transformations. It has been observed that the pharmaceutical manufacturing industry is regulated heavily since the beginning and hence it becomes more complex for its functions to be carried out simply. However, a heap of manufacturing operations into today’s digital space can prove disruptive to the supply chain of medicines.

Speaking about the current situation, since the World Health Organization declared the Covid-19 pandemic in 2020 the pharmaceutical manufacturing sciences sector has hugely burst into action and today several clinical trials are ongoing along with numerous vaccine manufacturing processes that are underway. But to bring true essence and a better pharmaceutical approach digital integration in this space must be necessary evolved irrespective of the number of challenges.

To take notice of the growing challenges in the pharmaceutical manufacturing industries it is mandatory to think about the pricing pressures in the market, the creative therapeutics, and global supply chains. However, bringing the real change in the manufacturing industry of pharmaceuticals will include shifting the thought process right beyond paper-based document management systems and by incorporating Artificial Intelligence and Big Data Technology.

Moreover, the change will include leveraging the industrial internet of things as well as machine learning techniques for additional optimistic effects on pharma manufacturing. This will surely enhance the overall processes and quality of the operations.

Let us learn more fascinating information about the future of pharma manufacturing in this blog.

The Breakthrough Technologies in Pharmaceutical Manufacturing

Every year there has been an abundance of creativity and advancements in the new drug therapies. But unfortunately, the present century has not experienced the true adoption of innovative pharmaceutical manufacturing technology. Speaking about the small molecule sector, continuous manufacturing has now been a focus area especially when it comes to new drug development.

On the other hand, the last molecule sector that was the point of single-handed technology has become a new trend, especially for low volume continuous manufacturing processes.

Even the researchers have concluded that the recent two decades have experienced a slow transformation for pharma manufacturing companies when speaking about new technology adoption. A few years back, pharma manufacturing companies were continuously introducing innovative technologies including automation. However, these emerging technologies have successfully revolved their continuous manufacturing operations but that was the time duration of 25 years ago and after that, the real craving for innovative manufacturing in the pharmaceutical space has completely diminished.

Hence, even the top experts in the pharma domain believe that now has come the right time for the pharmaceutical manufacturing sciences companies to completely transform the way they have been manufacturing.

The Impact Of Digitization

We all know that digital transformation or digitization is the new buzzword and when it comes to digitization in pharma manufacturing it becomes quite difficult to discuss. Because the domain considers paper-based structures that incessantly dominate shop floors as well as major business operations. Several software vendors cast their products as a method of digitization but digitization technologies were already observed three decades back. Even though these technologies are offering all the essential foundations, experts believe that digitization has not given so much of an impact on pharmaceutical manufacturing operations.

Transformation to a Service-oriented Approach

Even though there have been a lot of advances in medicine, pharmaceutical plant architecture has been constant in the last few years. However, manufacturing plants operate with legacy equipment while making use of traditional automation architectures.

The architecture makes use of different automation levels for different system types.

Let us take an example.

The top business applications such as product lifecycle management (PLM) or enterprise resource planning (ERP) will be managed at one architecture while the rest of the applications such as SCADA software for continuous manufacturing execution systems will be operated into another.

This shows that integration, as well as connectivity, is truly ambiguous in other manufacturing work environments but there is always a chance for the pharmaceutical industry to follow a particular process and this can be easily achieved with the help of digital advancements.

Also Read: How is Sage X3 helping Pharmaceutical Manufacturing Industries?

The Traditional Architecture Pattern

As compared to the other industry sectors, the pharmaceutical manufacturing sciences sector is surely risk-averse due to its complex regulatory demands and truly high weighted reputational impacts. For a long time, pharma manufacturing industries have been making use of traditional architecture patterns that might be tested and tried but do not assure an optimistic way to use the information in modern methods.

Suppose an executive wants to remove all the inefficiencies from the continuous manufacturing process and to achieve this he needs to examine the areas that need to be improved. Moreover, it needs to extract and remove the data subsets from various systems including SCADA, ERP, MES, and more. This shows that the executive would require various steps among enterprise production and laboratory to get all the required information. This clearly indicates that it is a very tough and time-consuming process to collect the data from a different set of systems.

Hence, pharma manufacturing industries should be incorporating a completely synchronized and user-friendly interface that will offer the executives the sure-shot and ready method to detect the lags and inefficiencies. However, the several innovative technologies may help generate high-level comprehensive integration for pharmaceutical manufacturers that may be a bit costly. In terms of architecture, the pharmaceutical manufacturing industry requires a thorough move from the traditional architecture type and should incorporate service-oriented architecture where integration will be the foremost and focused element.

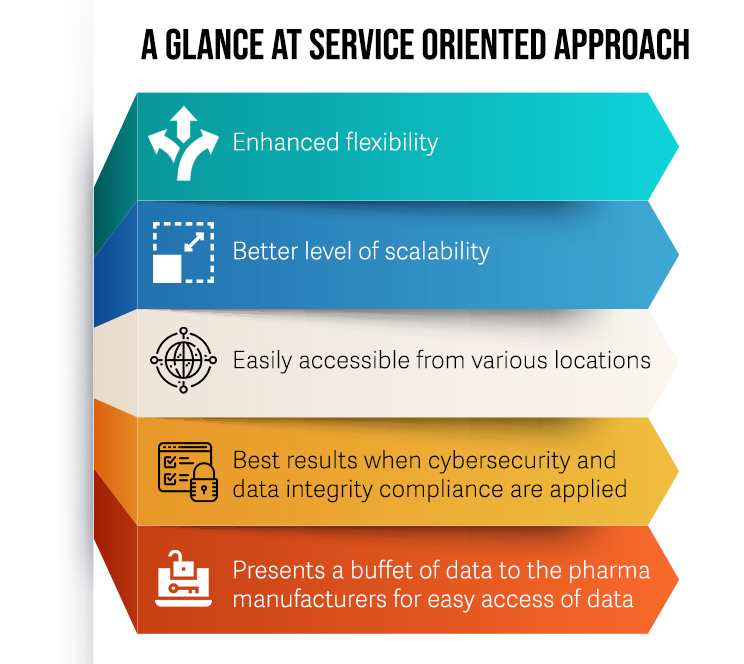

A Grasp of Service-oriented Structure

A service-oriented structure is usually operated as a set of modular microservices and allows a lot of flexibility as well as security by offering easy access to its user. This structure offers the strategy of a buffet of data from where pharmaceutical manufacturers can easily gain their benefits.

Besides offering greater flexibility, the structure also enables fast assembly and assembly of architecture systems. However, there is a better level of scalability when compared to the previous models since the data can be precisely organized and can be presented in such a way that will prove beneficial to whoever analyses it. Moreover, with this structure, the executive will not require to detect on what system the data set resides. Since the information will be disseminated in different services and can be easily accessed from a single interface irrespective of its location.

Additionally, in terms of pharmaceutical industries, the service-oriented structure can be easily incorporated while taking into consideration all the necessary cybersecurity as well as data integrity compliance essentials through validation and configuration processes.

Cutting-edge, Innovative, And Customized Healthcare

In order to deliver world-class treatment to the patients the most expert in the chemistry, biology and engineers can come together and build some better pharmaceutical manufacturing processes. However certain pharma companies are working with experts in dentistry to develop innovative technology that will address a number of challenges in the Pharma space. The technology developed by scientists will help pharmaceutical organizations to optimize the manufacturing of drugs and can help them produce wherever and whenever needed.

Additionally, this will also help reduced cost of the new medicines while transforming the overall Healthcare system which will be undoubtedly personalized, responsive, and acrobatic.

The Next-gen Manufacturing

In the next few years, the innovation centers across the globe will offer pharmaceutical companies technically advanced environments that can be easily accessed to build a responsive medicine supply chain for the pharmaceutical manufacturing sciences sector via manufacturing processes.

This strategy will ultimately offer outstanding solutions that can overcome the current supply chain floors and can assist new drugs to bring together today’s market more quickly and that too at a reduced cost. Advancements made in the manufacturing processes with the help of process analytical technology will have the capacity of offering deep insights of control over various protocols.

Artificial intelligence and big data will have a prime role in personalized medicine in which patient’s information will be collected from the medical devices as well as variables. However, the increased use of diagnostic tests and biomarkers will offer precision along with different populations. This will assist doctors to select the perfect medicine for the appropriate patient.

Speaking about the drugs that are getting produced today they all are one size fits all structure delivered to the pharmacies as per the national demand and the prescribed order history of the particular pharmacy. These drugs are produced in large batches which may prove inefficient for personalized medicine where only small batches of particular doses are required. The major impact of the drug data getting reduced with large batches is that they increase waste as well as inefficiency since a lot of drugs get seated on shelves for large periods. Moreover, the supply chains become incompatible to cope with the short-term changes in the demand for the drugs.

It is this reason why digitization must bring in healthcare as well as in the pharma manufacturing space so that the abrupt demand for various drugs can be easily predicted with greater precision.

By incorporating digitalization gives a golden opportunity for the manufacturers to develop excellent manufacturing methods that will help produce customized drugs wherever they are needed.

Also Read: ERP for Pharmaceutical Industry

How pharmaceutical manufacturing Industries Can Make Their Way Better

For several reasons, pharmaceutical manufacturers are highly advisable to move and incorporate the digital revolution that can be seen in other industries as well as in the consumer world over two decades back. However, the huge hurdle for pharma manufacturing industries to achieve progress is that the executives in the industry have not been considering the proper evolution of the manufacturing operations.

Likely in other industries, the increasing cost of the productions and the continuous requirement for product quality improvements are the most critical factors and with these elements, the companies need to compete. The pharmaceutical manufacturing industries do not have to confront this kind of pressure and hence it is more expected that these industries will bring in real efficiency and incorporate precise regulatory authorities to make the manufacturing process even more flawless.

Experts believe that there is one more hurdle in the way of pharma industries and this hurdle is the misconception that the evolving transparency in this manufacturing space may generate issues that may bring regulatory risks. However, this misconception must be resolved quickly if the pharma industries are looking for a bright future. There are scientists as well as a group of engineers that are continuously striving to resolve the problems related to manufacturing and to bring product quality and incorporate high levels of productivity. However, a fusion of comprehensive digital data and advanced analytical tools can be used.

Quick Tips

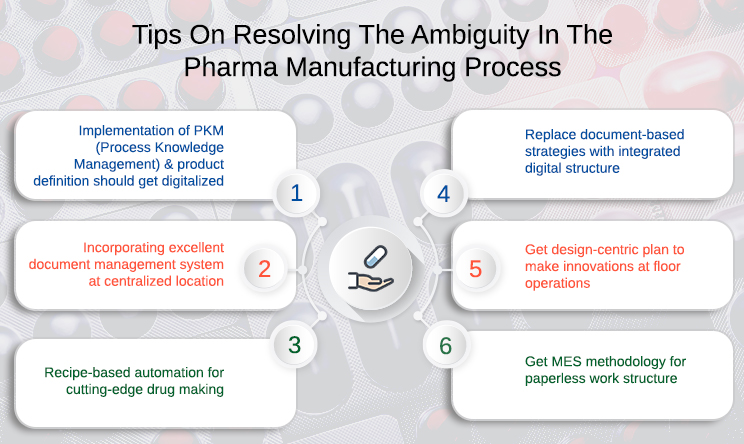

A quick look at the prime strategies that can be majorly used for achieving a complete transformation at the Pharmaceutical manufacturing level-

- Implementation of process knowledge management and product definition should get digitized and should go through every product life cycle that can start with the process analytical technology transfer from research and development.

- However digital transformation should take place taking into consideration that it is all about incorporating document management systems in one place. Also, this will mean that keeping digital process, design simulation, and modeling at the soft center of the manufacturing system structure will undoubtedly make the manufacturing operations seamless.

- More tough and study measurement, as well as control systems, should be deployed at the manufacturing levels. There should be recipe-based automation that can make real innovations in drug making. The advanced and completely evolved automation processes will be the most essential element for incessant manufacturing.

- Replace the document-based strategies of technical transfer, quality assurance, and knowledge management with a completely comprehensive and integrated digital structure that will place simulation, modeling, process designing at the core center of the information technology architecture.

- Incorporate a digital design-centric plan that will innovate shop floor operations through automation of recipes for manufacturing the execution and control systems.

- Implement MES approach to transform shop floor digitization. With MES, the pharmaceutical manufacturing industries can easily achieve a paperless and electronic batch record environment. In this approach, MES vendors should perform their role regularly by offering more innovative solutions that can allow customers to implement EBR.

If these things are incepted in the manufacturing plants, then pharma industries will undoubtedly be in a position to gain a complete digital transformation. However, the top-notch technologies such as cloud-based services, industrial internet of things, machine-based learning, and artificial intelligence will be easily accessible and will bring a new bright day of innovation.

A Wider Look Into The Future

As per the document released by FDA, it has stated that the future of pharma manufacturing domain experience and enhanced use of digital technologies as well as information. Hindi mid of this year’s brand initiatives including quality by design as well as right-first-time manufacturing will attain greater attention.

Today the workforce in the manufacturing industries has been increasingly becoming digital savvy since we cannot expect a heavy document-intensive industry to motivate the budding engineering brains. To collaborate with the top talent in the industry, Pharma manufacturers are highly advised to empower their workforces with the latest and advanced tools for the job.

To collaborate with the best talent, industries can completely equip shop floors with innovative technologies that continuously provide a thorough set of digital data that ensures the greatest product quality as well as efficient Pharmaceutical manufacturing operations.00

Down the line

Speaking clearly about the future of pharmaceutical manufacturing, experts have shared that even though the Covid-19 pandemic has been declared and there are other increasing diseases worldwide, the pharma industry should be moving fast along with the advancements in the technologies that will make the sector even more sustainable, flexible and scalable. Also, the manufacturers should welcome incredible transformation in service-oriented architectures and automation architectures that will keep the pace of the industry high.

It has been perfectly said that- “You can only improve what you can measure”. However, this statement perfectly touches the manufacturing domain as well since it depicts that we can only prove what we can measure and that includes pharma product quality and enhancement. Hence, this is the perfect time for Pharmaceutical manufacturing companies to keep their eyes tight on the digital age and bring in the most creative strategies.

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

If you liked this article, don’t forget to share the link with your friends. Also, follow us on:

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.