Summary: Supply chain functions in the chemical industry optimize warehouse, freight, distribution, and warehouse operations to run their everyday activities. As a result, challenges don’t come into the limelight unless something unexpected happens. But remember that even a small problem like a slight increase/decrease in chemical potency, lack of precise equipment, or not complying with industry standards can lead to huge problems. Therefore, the chemical industry needs to build supply chain strategies based on material allocation and customer commitments to handle such situations effectively.

The shape of the Chemical Industry

The current state of the supply chain in the Chemical Industry

Stakeholders in the chemical industry can be broadly classified into three categories: chemical manufacturing, chemical distribution, and chemical engineering.

-

Chemical manufacturers

They produce chemical products using raw materials such as natural materials, chemical compounds, and biological-based substances through a chemical reaction process.

-

Chemical distribution

They buy chemical products from chemical manufacturers and sell them to the end consumer (wholesalers, retailers, and governments).

-

Chemical engineering

They work with chemical scientists and professionals in developing new chemicals or upgrading the existing ones. Chemical engineers primarily focus on minimizing environmental impact, improving production processes, and solving real-life problems.

<<<Also Read: Meet chemical regulations through integrated traceability data>>>

How can I improve my chemical supply chain?

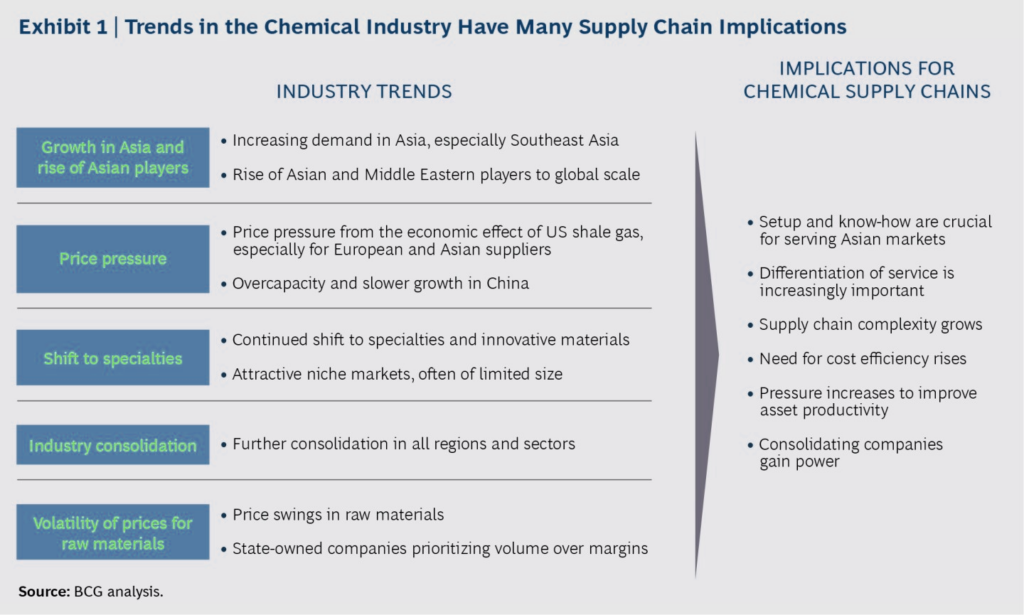

The chemical industry is globalizing, increasing the volatility in raw material costs. Also, service improvements in other sectors worldwide encourage customers to demand better service. Moreover, mergers between chemical giants like Clariant and Huntsman, and Dow and DuPont are consolidating the chemical industry further. Further, established businesses are also facing increased competition from new players.

The points mentioned above put undue stress on the chemical industry’s supply chain, for which they must find cost-effective solutions. Therefore cutting-edge technology that can improve service performance, minimize working capital, increase asset productivity, and provide significant market power is the need of the hour.

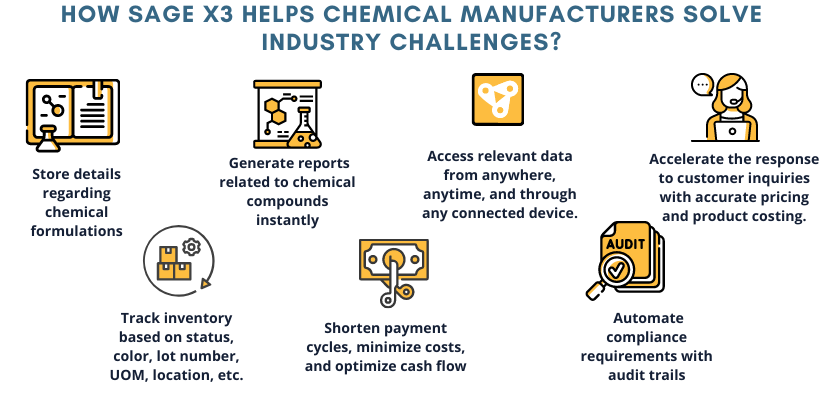

Here’s how erp for chemical manufacturing helps chemical manufacturers to efficiently manage their supply chain .

1. The Five-Layer Framework

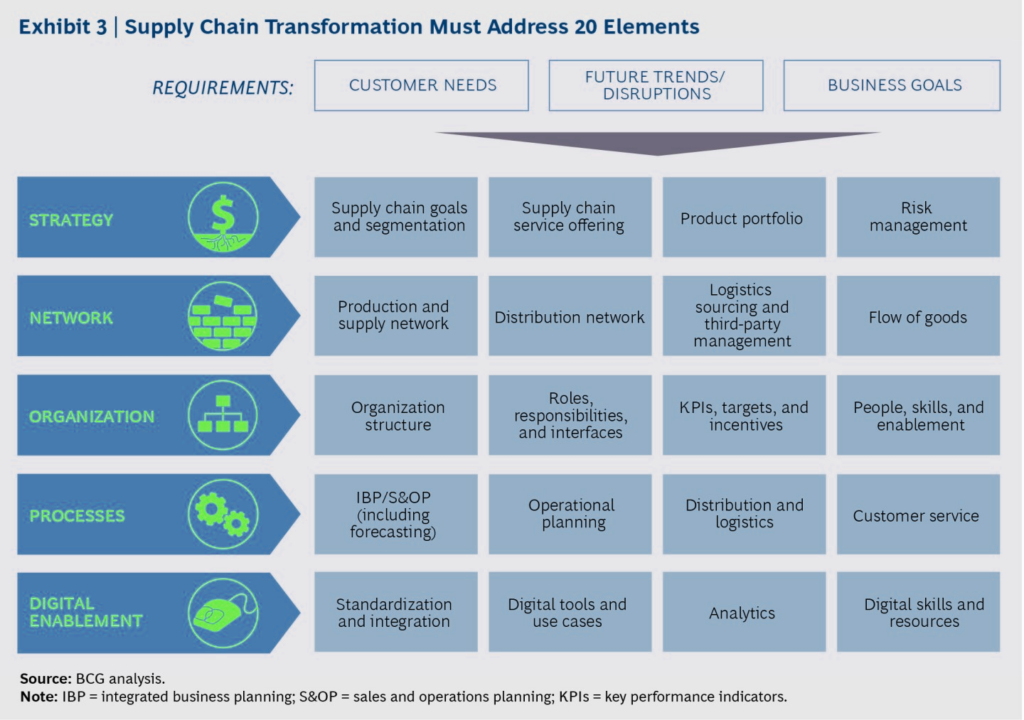

BCG has prepared an excellent infographic containing 20 elements distributed across five layers, including network, processes, strategy, digital enablement, and organization. It’s called the five-layer framework that explains how companies in the chemical industry can improve their supply chains:

Don’t forget to give appropriate credits to BCG in the infographic above.

Here’s a brief description of the elements in the infographic:

-

Strategy

In this layer, companies create various product segmentations based on which they prepare goals, processes, and policies for each segment. In addition, businesses can go a step ahead and generate niche segments based on various parameters like margins, volume, and life-cycle stage. Product segmentation is essential as it allows organizations to devote their resources to vital products instead of others.

-

Network

Many chemical companies created their supply chain — transportation flows, warehousing operations, inventory management, insourcing of raw materials and outsourcing of finished products long back. Therefore they aren’t aligned with recent development in the logistics marketplaces. Networking allows companies to minimize delivery lead times, reduce logistics costs, and maximize product availability by using local hubs and developing better outsourcing strategies.

-

Organization

This layer has two aspects. Firstly, the interfaces between the critical supply chain functions like manufacturing, logistics, sales, and marketing aren’t appropriately defined. A perfect solution to this challenge is by assigning roles & responsibilities and setting metrics and goals for measuring accountability. This method will facilitate the smooth functioning of the supply chain.

Secondly, setting Key Performance indicators (KPIs) and incentives is essential for ensuring high-level supply chain performance. An easy-to-use dashboard provides an in-depth understanding of the performance metrics allowing senior management to track the performance of each employee.

-

Processes

There are two sublayers within this layer. The first one is Integrated Business Planning (IBP) also called Sales & Operations Planning (S&OP). It helps maintain a healthy balance between demand and supply across each business function. Moreover, it takes care of seasonal shifts in product demand, long process times, and large batch sizes.

The second sublayer is short-term operation planning for inventory. It helps maintain an adequate inventory by applying advanced product analytics models, creating high-quality service levels, and handling inventory targets across numerous supply chain stages.

-

Digital enablement

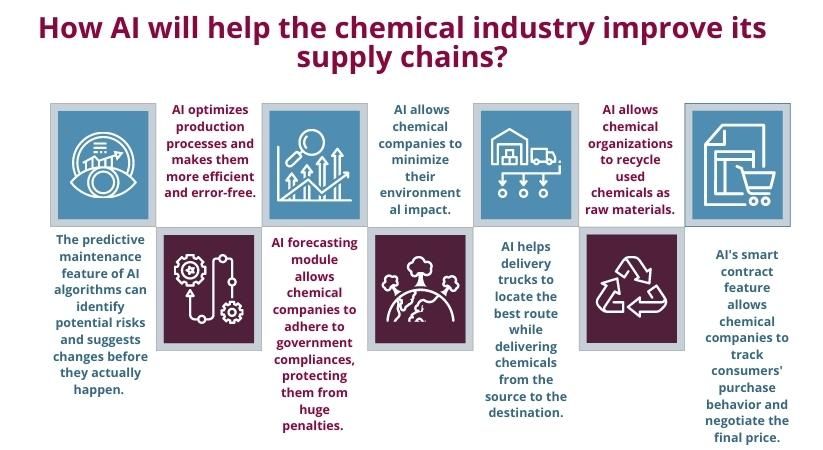

Digital technologies have helped companies in the chemical industry achieve supply-chain-specific goals for decades. But contemporary digital technologies like IoT, AI, machine learning, and cognitive computing also support operational execution and decision-making capabilities. Digital enablement can be subdivided into three categories:

a. End-to-end planning

These technologies allow companies in the chemical industry to make advanced business decisions, bolster the planning process, and forecast the performance of particular sectors. The best part is that these tools write planning decisions inside the Enterprise Resource Planning (ERP) systems and handle any adjustments.

b. Specific activities

These advanced tools tailor specific supply chain processes, including logistics, warehousing, transportation, and commissioning. They take data from multiple sources and provide mobile-ready intuitive data.

2. Trends that are putting undue pressure on the chemical industry’s supply chain.

3. Supply Chain differential

Robust customer orientation and supply chain excellence create immense value for industry leaders in the chemical industry. Unfortunately, companies have invested time and resources in improving their supply chain initiatives, but due to the industry’s growing product complexity and expanding customer base, it has ample room for improvement. Also, many companies have given unwanted attention to understanding customers’ perspectives. Due to these factors, organizations have high inventory and logistics costs, and they perform weakly on supply chain metrics like delivery service and lead times that impact customer experiences.

On the contrary, supply chain leaders incur low costs and achieve higher growth levels with greater efficiency and customer satisfaction. For example, BCG reports that industry leaders turn over their inventory 14 times compared to 6 times by worst performers. Moreover, top performers spend 2.2% of their revenue on transportation costs compared with 3.6% paid by worst performers.

While distinct regions, differing business models, and varying product offers are minor factors for this variation, the different ways chemical companies design, operate and run their supply chains are the primary determinants of this variation.

Organizations can significantly improve their supply chains by strengthening planning & forecasting, introducing lean processes, and establishing regional operations. Moreover, companies can better their asset productivity by aligning manufacturing and planning activities. Further, by brainstorming their inventory strategies, chemical enterprises can lessen their working capital, improving their cash flow.

<<<Also Read: ERP for Chemical Industry: Proven Formula for Success and Growth>>>

Customer experience, the final stage in the supply chain, offers substantial improvement opportunities. Earlier, excellent use of production assets and R&D — instead of customer behavior and developments in market trends ensured success in the chemical industry.

But today, the rise in positive customer experiences in other industries like eCommerce and industrial services has also raised customer expectations in the chemical industry. Therefore, customer interactions, including product information and product updates via social media apps, have become effective ways to establish robust and long-lasting customer relationships.

Remember that an efficient supply chain is a cornerstone of specialty chemical and commodity businesses, although for varying reasons. For example:

- Short lead times and robust customer relationships in specialty chemical businesses ensure productivity.

- Building efficient supply chains increase market share in commodities.

The future of the supply chain in the Chemical Industry

Minimizing wastage, better resource management, and fulfilling customer & market needs will be the three fundamental pillars of the chemical industry in the future. To realize these goals, the chemical industry needs to adopt a more circular economy mindset to create customer value through operational change. The following points explain how:

- Building a broad portfolio of services and products for end consumers.

- Innovating new products based on market trends and customer preferences.

- Expanding the target audience will help increase profits.

- Working together with customers to build customized products.

STAY UPDATED

Subscribe To Our Newsletter

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.