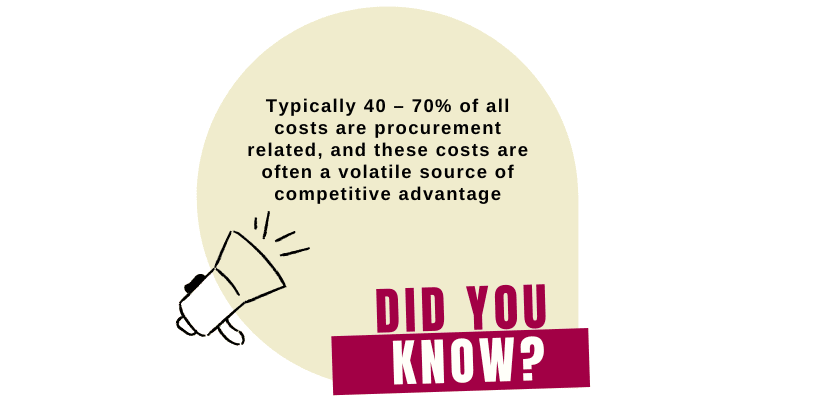

Summary: Procurement constitutes the transactional part of the business. It involves buying raw materials from vendors & suppliers at the most affordable rates. Although the techniques and methods of procurement have drastically changed over the years, the general principle remains the same i.e. getting essential supplies at the cheapest rates and on time. Therefore, qualified professionals need to monitor each component of the procurement process as it directly impacts a business’s bottom line.

What is Procurement?

Generally speaking, procurement is a collection of multiple processes and activities allowing businesses to acquire the best quality raw materials at competitive prices and within the stipulated deadline.

However, different companies define procurement differently.

For example, for company A, procurement might mean determining business needs, identifying suppliers, generating & tracking receipts of goods, and redefining, updating, and negotiating payment terms based on the inputs collected from involved parties.

On the other hand, company B might have a narrower view of procurement, including only the generation of purchase orders and making the final payment.

Why is Procurement critical to your business?

A well-managed procurement process helps identify reliable vendors and suppliers. A reliable vendor ensures you get essential supplies at the most competitive rates and within the specified date and time.

Many companies waste significant time, resources, and money dealing with inefficient suppliers. As a result, they get substandard materials.

Another challenge is that many suppliers either don’t keep records or use traditional methods like pen and paper. They don’t use automated solutions like ERP systems to maintain and update records which wastes significant time and leads to human-induced errors.

A well-managed procurement process solves the following challenges:

- Helps identify reliable vendors and suppliers.

- Reduce the cost of purchase of raw materials.

- Ensures materials are delivered on time.

- Maintains procurement records safely in ERP software.

<<<Also Read: Difference between Procurement and Purchasing>>>

Types of Procurement

Procurement can be categorized as direct and indirect based on how the company will use the items after procuring them.

- Direct Procurement

It refers to procuring raw materials required to manufacture an end product. For example, a tyre manufacturer would procure rubber for producing tyres. Or a retailer would procure sugar from a wholesaler to further sell it to customers.

-

Indirect Procurement

It includes materials that don’t directly contribute to the company’s bottom line but play a significant role in executing day-to-day business operations. Examples include office supplies such as furniture, equipment maintenance, after-sales service, and running ads on social media.

Procurement can also be classified as goods and services based on the type of items being procured.

-

Goods procurement

It refers to procuring physical items & equipment but can also include digital products like software subscriptions. An efficient supply chain plays an important role, without which you might get low-quality products and experience a delay in receiving goods. Most importantly, both direct and indirect procurement form a crucial part of goods procurement.

-

Services procurement

This category includes people-based services. It differs from company to company, but it generally consists of:

a. After-sales executives

b. On-site laborers

c. Individual contractors

d. On-site security services

Both direct and indirect procurement form a critical part of services procurement.

9 critical parts of the procurement process

Although the procurement process greatly varies from one company to another, it consists of all or some of the points mentioned below:

1. Identifying products and services critical to a business

Initially, a company should identify the products and services it requires based on its needs and requirements. For example, it might include a brand new product that the company hasn’t previously purchased, restocking supplies of existing products, or renewing a service.

Here’s what you must take care of:

- Type of material/service

- The exact quantity of products

- Precise technical specifications of products

- Service characteristics

- Part numbers

It’s best to consult all business departments before making the final purchase, ensuring the procured item fulfills the needs of each department.

2. Submit a purchase request

Making a formal purchase request, also known as purchase requisition, makes sense if you want to purchase a large number of items or services in one go.

Usually, the procurement department manager creates a purchase request listing down the department’s needs and the technical specifications of the product specified. It includes:

- Price format

- Time duration

- Quantity required

- Size/dimensions

- Installation

- Performance

- Supplier experience

The purchase request is finally sent to the finance & accounting department, which decides to approve or deny it.

If approved, the procurement team can start the vendor selection process. If denied, both teams can sit together to identify & eliminate unrequired expenses and only pay for items critical to the department’s functioning.

3. Identify and select the best vendor

After the finance & accounting department approves the purchase request, it’s time to identify the best vendor and submit a Request for Quote (RFQ).

The procurement team sends the RFQ to potential suppliers to receive a quote. And therefore, the RFQ should provide a detailed description of your business needs to the vendors.

Here’s what you should focus on during the vendor assessment process:

- Quality, Cost, and Delivery (QCD)

- Total Quality Performance (TQP)

- Regulatory compliance risk

- Financial Stability

- Past industry experience

- Service quality

- Delivery time

- Cyber risk

Today, many retailers take pride in implementing eco-friendly policies. Therefore, it would be best if you tie up with a supplier that stands with environmental sustainability issues. This way, you can strengthen your corporate identity and build a brand in the market.

<<<Also Read: Top 10 ERP Vendor Evaluation & Selection Criteria>>>

4. Working out the price and terms

The industry practice is to get at least 3 quotes from suppliers before reaching the final decision. You should critically analyze each quote and identify clauses where you can negotiate to get a better deal. If you aren’t satisfied with the procurement terms, have several alternate suppliers before calling it quits. And if you agree to go ahead with the supplier, ensure that you create a written document mentioning all terms and clauses.

5. Generate a purchase order

Create and fill a Purchase Order (PO) and forward it to the supplier. Ensure that the PO contains all details regarding the goods and services you need and the stipulated time within which the supplier should fulfill the order.

6. Examine the received goods

Once you receive the deliveries in your warehouse, check for any discrepancies, damage, or errors. Ensure that you have received each item mentioned in the PO and also check their quality — substandard, average, or excellent.

7. Perform three-way matching

To avoid discrepancies or errors, the accounts payable team should perform three-way matching, which includes comparing the order receipt (packing list), purchase order, and invoice. The primary objective of this step is to ensure you don’t pay for inaccurate or unauthorized invoices.

8. Make the final payment

If there are no discrepancies in the three-way matching process and everything is accurate, you should pay the invoice. An error-free account payable process helps verify that any payments you make match the invoice. This process ensures that payments are always made on time, helping build robust and long-lasting supplier relationships and preventing late fees.

9. Record keeping

Storing and maintaining records for the entire procurement process, from identifying essential materials and generating purchase orders to creating RFQ and paying invoices, is beneficial for multiple reasons.

They help:

- Reordering goods at competitive prices in the future.

- Calculate taxes

- Assist in the auditing process

- Resolve potential issues that might arise in the future