What Is Multiple Step Operational Loss?

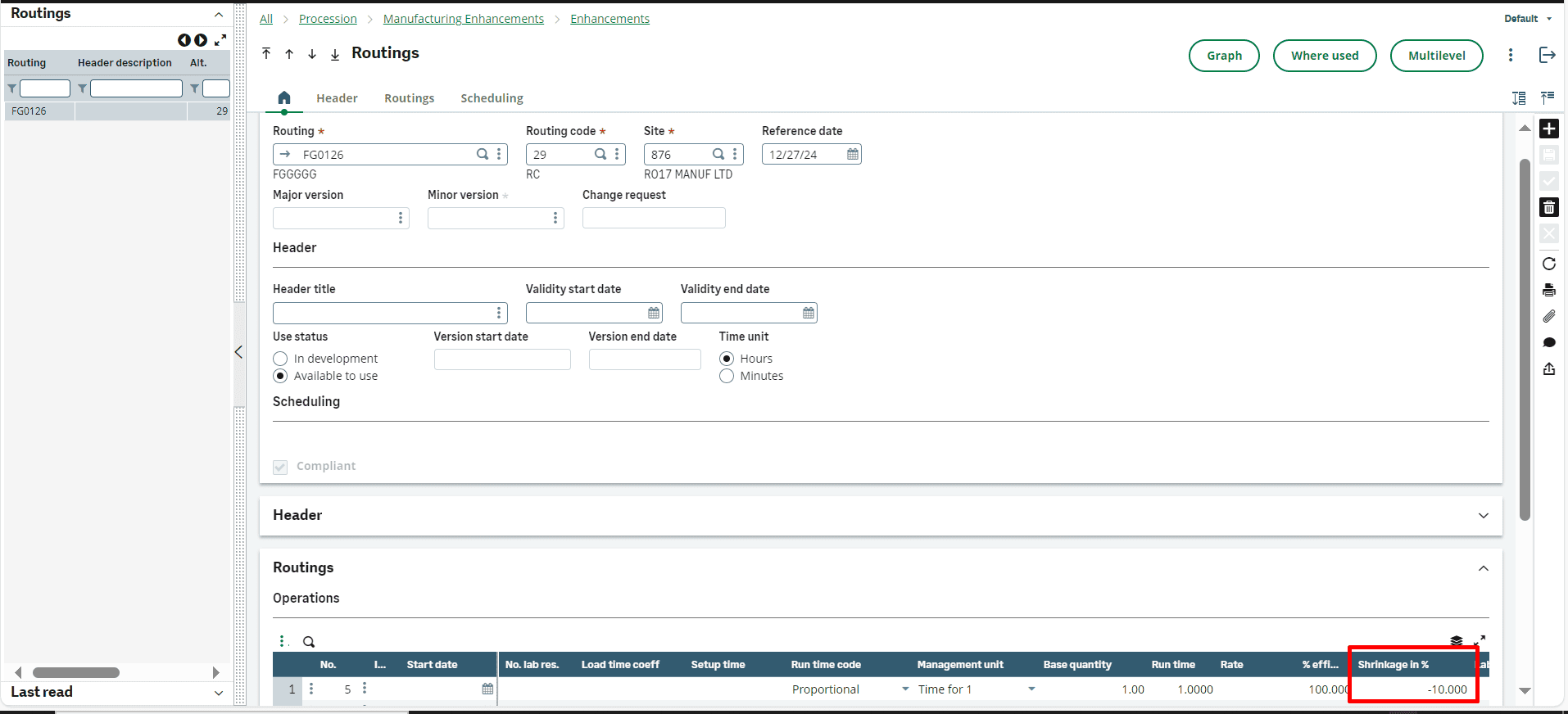

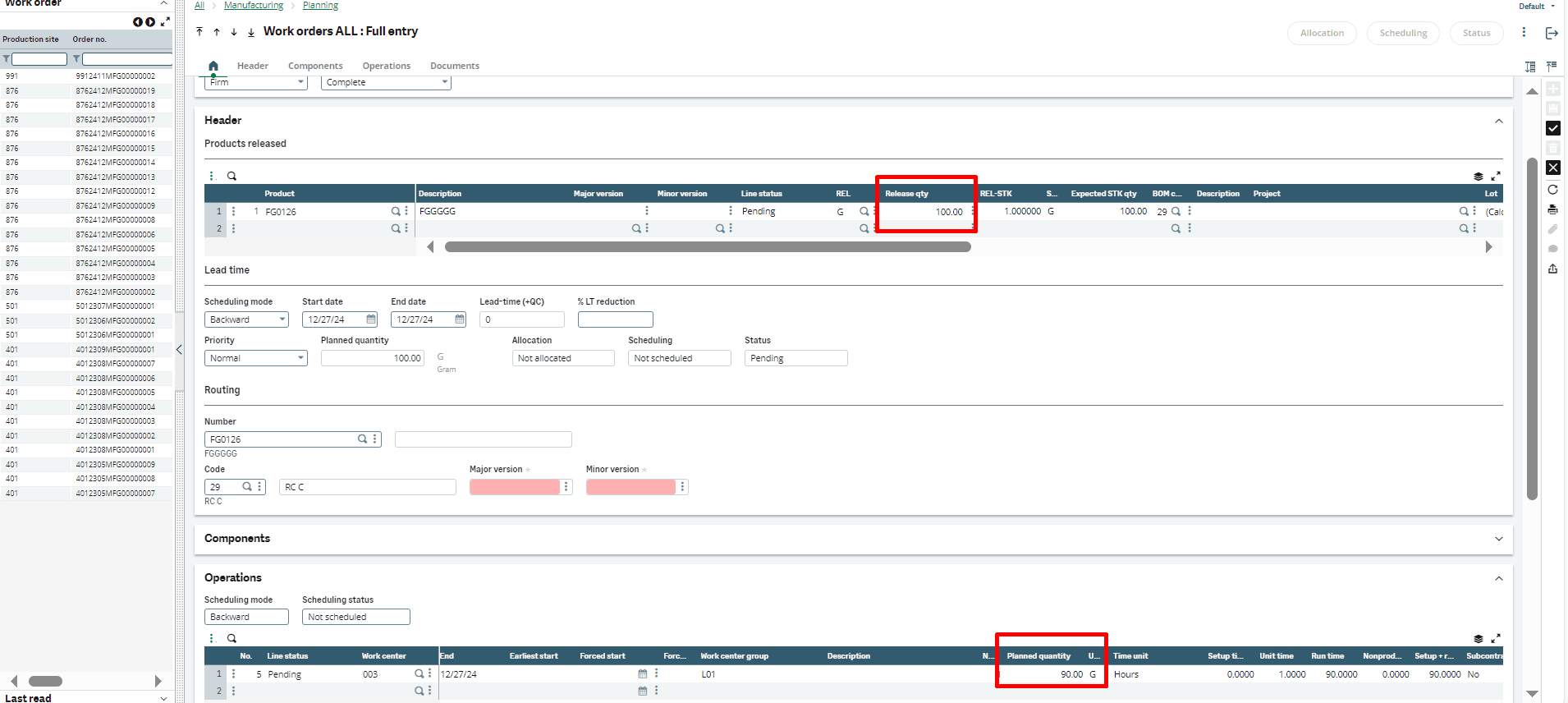

We can define scrap loss for each raw material as well as operation loss against each step of our production. Scrap loss calculation is forward calculation but operation loss is backward calculation. For example, if you have defined a loss of 10 percent in any process and you are creating a work order of 100 units, then system will inform you that with 10% loss you can make 90 units.

Example Of Multiple Step Operational Loss.

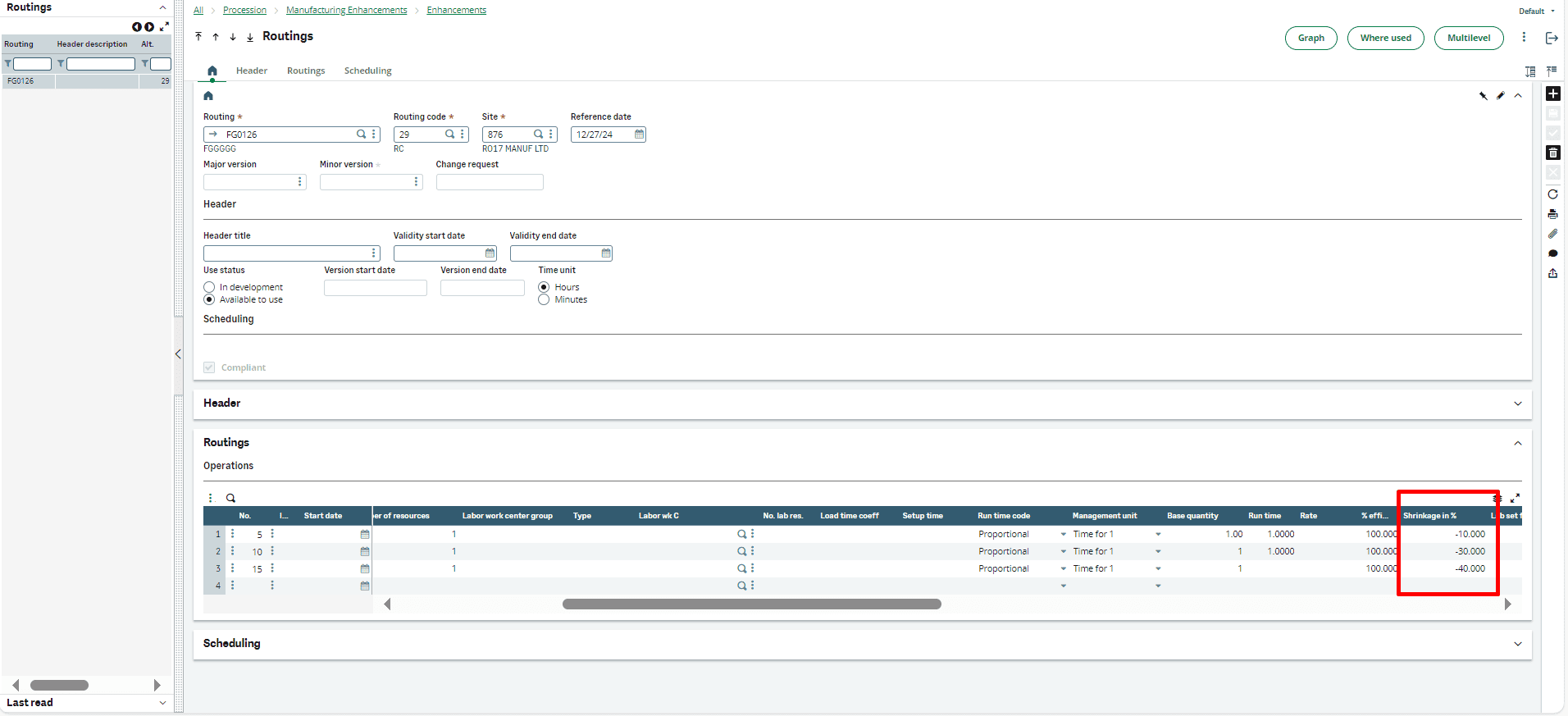

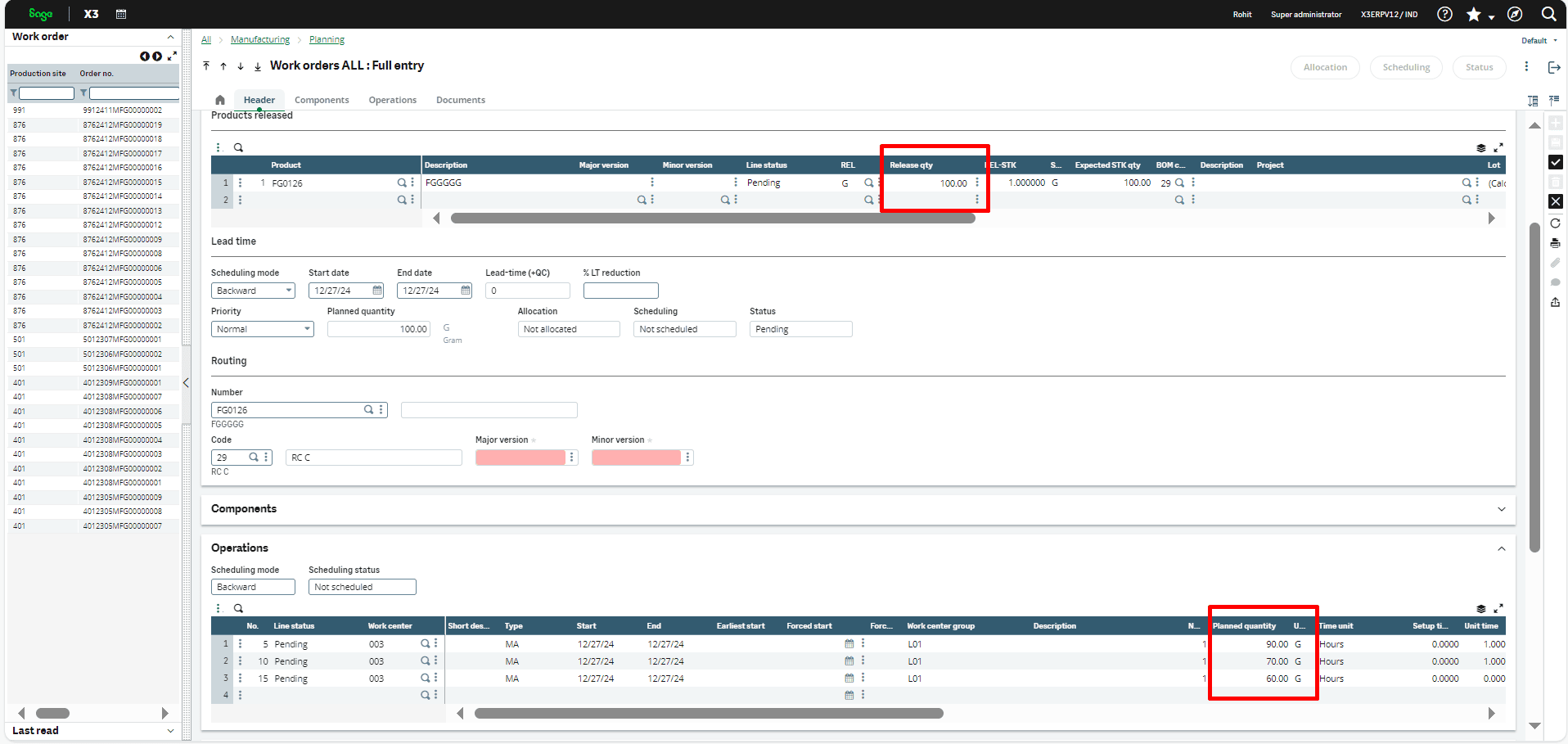

Also, in multiple step/process/operation this individual loss has to be added and feed to system as you can see in the below screenshot. Here also the calculation of Finished Goods will be backward.

Example- suppose I have defined a loss of 10 % for operation 1, 20 % loss for process 2 and 10 % loss for process 3 on routing. If I am making a work order of 100 units, then the system will inform that you will get (100 units – 10%) after operation 1(90 units), (90 – 20% of 100)= (70 units) after operation 2 and (70- 10% of 100)= (60units) after operation 3.