Summary: You earn money when your inventory goes out of the warehouse. But do you have a 360-degree view of how the inventory is moving — from the initial receipt to shipping. The most important pillar for establishing a profitable business is total visibility of the inventory process from beginning to end. And it comes by implementing an inventory management system that keeps optimal inventory stock and supply chain organized throughout the year.

This blog will offer knowledge regarding inventory management and how an inventory management system will help you increase profitability and eliminate waste.

Disadvantages of inefficient inventory management

Inventory is the most significant asset that businesses of all sizes own. And therefore, inventory mismanagement is one of the biggest reasons small and medium-sized businesses fail.

Here are a few disadvantages you will face due to inefficient inventory management:

-

Longer lead time

If you are aware of the changing market trends and customer preferences, you will always stay ahead of the market curve. You can capitalize on popular items that customers are more likely to purchase, multiplying your profits.

-

Excessive stock

If you have excessive stock, you are wasting a lot of money. Firstly, you are paying too much for renting warehouse space. And secondly, many perishable products decay even before you can sell them.

-

Inadequate stock

If you don’t have adequate supplies of products that customers want, they will look out for other sellers. Therefore, if you face stockouts too often, you will lose a large base of your customers.

What is an inventory management system and how can it help you?

To establish a profitable business, you must track and manage inventory quickly and efficiently. The benefits of inventory management software are:

- Optimal stock of products

- Quick and easy transportation of products from the vendor’s location to your warehouse.

- Easy picking, packing, and labeling.

- Eliminates product spoilage.

- Protects against product stockouts.

Earlier, companies used to count each item manually and record the figures using the traditional pen and paper format. But with a digital inventory management system, you save money and also eliminate human-induced errors. Moreover, finance professionals can focus on mission-critical tasks instead of wasting time on managing accounts.

The key capabilities of inventory management software include:

- Asset tracking

- Product identification

- Inventory optimization

- Service management

Inventory management software provides real-time inventory status allowing you to maintain adequate stocks. But simultaneously, it also offers insights into the changing market trends and customer preferences so that you don’t lose on sales opportunities and increase your customer base.

<<<Also Read: Top inventory management techniques SMEs must follow>>>

Perpetual vs. Periodic inventory management software

You can choose amongst different types of inventory management software — Perpetual and Periodic inventory systems.

Periodic Inventory

Small businesses that have less inventory to manage and lack sufficient investment to implement a full-fledged computerized system opt for periodic inventory. They physically count the inventory and the Cost Of Goods Sold (COGS).

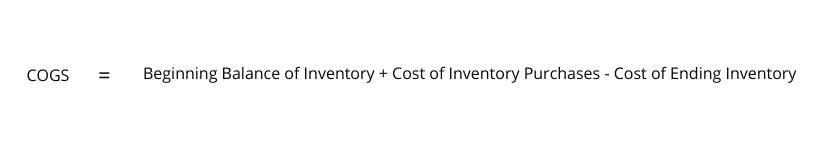

A company’s gross margin is calculated by subtracting COGS from revenue. Here’s the formula for calculating COGS in the periodic inventory system:

Companies are often unaware of the exact quantity of stock they have in the warehouse. As a result, they conduct physical counts every week, month, or quarter.

Here’s a brief description of the process:

- A physical count is done and the inventory records at the end of the period are counted.

- Merchandise purchases are updated in the purchases account.

- Then the inventory account is updated.

- This new balance acts as the balance for the next period and the process starts again.

The only disadvantage of periodic inventory is that companies have to count and update every physical quantity in the inventory, which is time-consuming and prone to error. Consider an electronic equipment manufacturer with multiple warehouses worldwide purchasing various parts required for manufacturing a smartphone. Now, imagine a large team counting each such part. Can you imagine the time spent performing this activity? Consequently, companies perform physical count once a month, quarter, or year.

Perpetual Inventory

The perpetual inventory systems measures inventory balance in real-time using computerized systems. Point of sale (POS) systems record inventory purchases and sales accurately (unless goods aren’t damaged or broken). Moreover, the COGS account is also updated as soon as a sale is made and the data is sent to central databases in real-time. Perpetual inventory uses technology to its fullest; therefore, the workforce plays a minor role compared to the periodic inventory.

Here’s a brief description of the process:

- Each product has a barcode that tracks the product’s real-time location and records how long it has been on the shelf.

- The inventory management system updates whenever a product moves outside (or inside) the inventory using point-of-sale inventory.

- It contains multiple ledgers for COGS, purchases, and leftover stock.

However, implementing, updating, and maintaining an inventory management system is costly. But the advantages outweigh the disadvantages easily. For example:

- It provides real-time monitoring.

- Since all operations are automated, it’s easier to use than periodic inventory.

- It’s more accurate than physical counts.

- The barcodes attached to products allow the shop floor manager to get detailed information about that product.

How are inventory and accounting related?

Inventory is a business asset and therefore, inventory management and accounting are intimately connected. It would be best if your inventory management software contains numerous inventory valuation methods. It helps extract real-time metrics about products at each step in the process.

Here’s a list of essential inventory valuation functions your inventory management software must contain:

1. Weighted average costing

This function is calculated by dividing the total cost of goods available for sale by the total number of goods.

2. Inventory turnover rate

This function is calculated by dividing the cost of goods sold by the average inventory in hand.

Here are a few factors you should remember:

- A high turnover rate corresponds to excessive shipping costs to quickly fill stocks of necessary items, wasted time locating misplaced or lost items, and fulfilling incomplete orders.

- A low turnover rate corresponds to diminishing inventory value and duplicate orders.

- A balanced turnover rate signifies lower costs, high efficiency, and greater customer satisfaction.

3. Bills Of Materials (BOM)

Contains the list of sub-items that form a single inventory item.

4. Standard costing

The accounting records contain two values — The actual cost of the product and the expected cost of an item. The variance between the two values is updated in the accounting records. Companies use this method mostly when it takes substantial time to track actual costs in real-time.

5. Kitting

Assembling parts and items to form a single finished item.

6. Work in Progress

Monitors inventory progress from the manufacturing facility to the shop floor where it’s finally used.

7. Just In time (JIT) inventory

It refers to receiving inventory just before or exactly at the predetermined time.

6 essential things you should look for in an inventory management system

An inventory management system is a critical part of Enterprise Resource Planning (ERP) software. ERP unifies various modules, including accounting, point-of-sale, inventory management, and supply chain management, into a single platform providing the required efficiency.

1. Business visibility

Cloud-based inventory management systems enable businesses to collect, store and analyze inventory data in real-time. Other advantages include generating highly detailed reports for improved collaboration and accessing crucial data from anywhere, anytime, and on any connected device.

2. Integration

Without integrating the inventory management system with the ERP software or other back-end and front-end business applications, it might not be as effective.

3. AI & data analytics

Built-in AI capabilities provide suggestions regarding changing market trends and customer preferences, what customers are most likely to purchase in the coming future and data-based recommendations for inventory levels.

4. Affordability & Scalability

Inventory management systems come in varying shapes and sizes. Therefore, it would be best to identify your business needs, which will help you zero in on the essential modules required to perform your business functions quickly and efficiently. Also, ensure that you implement a scalable ERP system, meaning it can add new modules as your business expands.

5. Implementation & maintenance

The best part about cloud-based inventory management software is that it’s easy to implement and update compared to on-premise solutions. In addition, cloud-based solutions have cutting-edge security features that are updated automatically. On the other hand, on-premise solutions take time to update and are vulnerable to external attacks.

6. Product tracking

Inventory management software should be able to track the real-time location of inventory while it’s moving across the supply chain. Also, you must check that the software is compatible with bar code scanners enabling you to scan product details instantly.