Inventory management is a critical part of any business, but it plays a vital role for small businesses. By keeping a careful eye on inventory levels, companies can ensure that they are not overstocking or understocking items, leading to lost sales and profits. Deploying an inventory management software helps attain the desired outputs from your business.

What is Inventory Management?

It is the process of tracking and controlling the inventory of a company. This includes the ordering, receiving, storing, and shipping of products. It is an integral part of any business, as it helps to ensure that the company has the right products available at the right time.

Many factors go into effective inventory management systems. One key consideration is the type of products that are being handled. Some products are more prone to spoilage or damage than others and require different storage and handling procedures.

Another critical factor is the space available for inventory. Companies need to ensure that they have enough space to store all of their products and enough room to move them around. This can be a challenge, especially in smaller businesses where space is limited.

It also involves keeping track of stock levels and ordering new stock when necessary. This requires accurate records of what products are being sold and when they are selling out. It is also mandatory to plan for seasonal fluctuations in demand.

Overall, adequate inventory is needed for any business. It helps to ensure that products are available when customers need them while minimizing inventory costs.

Also Read: TOP 10 ERP Modules: The Complete List (2023)

Inventory management software helps you ensure you have enough stock to fulfil customer orders and lowers the price associated with excess inventory. Proper inventory management processes benefit for small businesses through improved competency, better customer service, enhanced visibility and control over stock levels, and cost savings.

- Efficiency is improved by having a central system to manage inventory levels. It enables you to keep track of stock levels in real time and lower the risk of running out of items or ordering too much. The system also gives you better control over when and how orders are fulfilled, allowing you to make sure orders are shipped quickly and accurately.

- Better customer service is achieved through having access to accurate real-time information about stock levels. You can provide customers with precise data about order times and availability which helps to guarantee customer satisfaction.

- Having an inventory management system gives you visibility and control over stock levels. You will be able to identify optimal stocking levels and keep track of what is ordered, received and sold. It helps to ensure stock levels are kept up to date and minimize the risk of running out of stock.

- It helps to reduce expenses associated with excess stock. By managing stock levels accurately, you can avoid unnecessary expenditure associated with storing and managing excess inventory.

Also Read: Best Ways of Tracking Inventory for the Food Manufacturing Industry

Different Types of Inventory

Various types of inventory serve various purposes and must be managed accordingly.

Common inventory types include raw materials, work-in-progress inventories, final goods, maintenance, repair, and operations (MRO) inventory. Knowing the differences between these types of inventory makes for more efficient inventory.

Raw materials inventory is the materials used to manufacture products. It is usually the first type of inventory to enter a company’s system.

Work-in-progress inventory is the unfinished products, typically consisting of raw materials that are turned into finished goods.

Finished goods inventory is the completed product ready for sale to consumers. MRO inventory encompasses any other type of inventory required for the operation of the business, such as office supplies and tools.

By understanding the different types of inventory and their use, businesses can better manage their lists, ensuring they have enough raw materials, products, and equipment to keep operations running.

Also Read: How efficient Cost Control impacts your Supplies Inventory?

Inventory Management Techniques

Inventory management software is essential for businesses of all sizes. It helps keep track of materials, products, and supplies so you can stay systematic and increase customer satisfaction. However, the proper techniques can reduce waste and maximize profitability.

Here are some techniques to help you better manage your inventory –

1. Implement a Reorder Point System :

Reorder point systems keep track of stock levels and alert you when it is time to reorder. It helps you avoid stocking too many or too few products, which can lead to excess costs and customer dissatisfaction.

2. Utilize Software :

Software like ERP systems, WMS, and BI help you track inventory in real time, getting accurate data about stock levels, sales, and projections.

3. Create an Efficient Layout :

With the help of an ergonomics specialist, create an efficient warehouse layout for workers. It helps increase productivity, eliminate extra expense and save time by reducing errors and miscommunication.

4. Cross Docking :

Cross docking helps reconcile inventory with incoming and outgoing shipments, reducing handling and storage expenses and streamlining the delivery process.

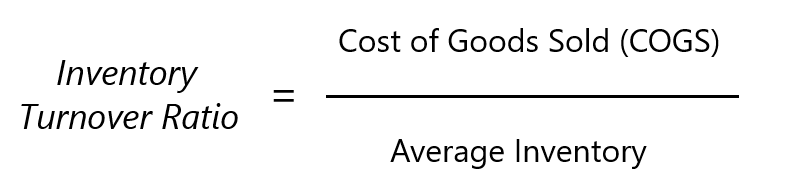

5. Analyze Inventory Turnover :

Analyzing your inventory management software turnover rate is essential to determine stock levels and identify any problems. Implementing these techniques can increase effectiveness, and improve customer satisfaction.

Also Read: How to better manage Inventory in the Food Production Industry?

Challenges Small Businesses Face with Inventory Management

One of the main challenges businesses face with inventory management is ensuring that they have an adequate supply of products to meet customer demand. It can be challenging if the company cannot forecast demand accurately and becomes challenging for supply chain management.

Small businesses may also need more resources to invest in sophisticated inventory-tracking software, making it difficult to track what is on hand and what needs to be ordered.

Another challenge is ensuring that inventory is properly stored and organized, which can be difficult if the business is limited in terms of storage space. Finally, businesses need to be mindful of the inventory cost and carry enough stock.

Wrapping Up

Small businesses that take the time to implement a sound inventory management software can see many plus points, including high profits and reduced risk of stockouts. By taking advantage of modern inventory software, businesses can stay competitive and successful in today’s economy.

Sage Software Solutions is a leading IT company with an array of advanced ERP Software solutions. Our proprietary products — Sage X3 and Sage 300, will help you cut operational expenses, improve business productivity, increase operational efficiency, forge robust customer relationships, and strengthen associations with vendors, suppliers, and distributors. So, if you are looking to reinforce your business fundamentals and emerge as an industry leader, then please schedule a call with one of our sales representatives.