Summary: The Internet of Things (IoT) has undergone a wave of developments recently. Things are proceeding at a lightning-fast speed, from introducing tiny sensors that can fit in small parts to intelligent systems that can operate without human help. The day is not far away when our refrigerators will purchase food ingredients on their own and driverless cars will roam around the streets. Internet of Things platforms also provide top-notch solutions in the pharmaceutical industry by boosting drug and medical equipment manufacturing processes, reducing operational expenses, assuring product quality, and complying with government norms. Interconnected devices are helping pharmaceutical manufacturers to track the availability of raw ingredients, manage the shop floor efficiently, trace lot numbers conveniently, and prepare precision medicines as per the customer specifications.

The pharma sector is growing by leaps and bounds. Research shows that the pharma sector in India will swell to USD 130 billion by 2030 at a CAGR of 12%. Developments in Internet of Things are playing an essential role in the success of the Indian pharma sector. Unlike the past, today, Internet of Things devices provide lag-free real-time data instantly, allow sharing critical business data with stakeholders, and most importantly, have become inexpensive. Also, the pharmaceutical manufacturing sector realizes the power of digitization and its long-term benefits. Statista reports that there are 21.5 billion interconnected devices worldwide and this figure is set to explode as the Internet spreads far and wide.

So, how will this explosive boom in IoT devices play its role in the pharma sector? Let’s delve deep and find it out.

1. Supply chain activities will become smoother and convenient.

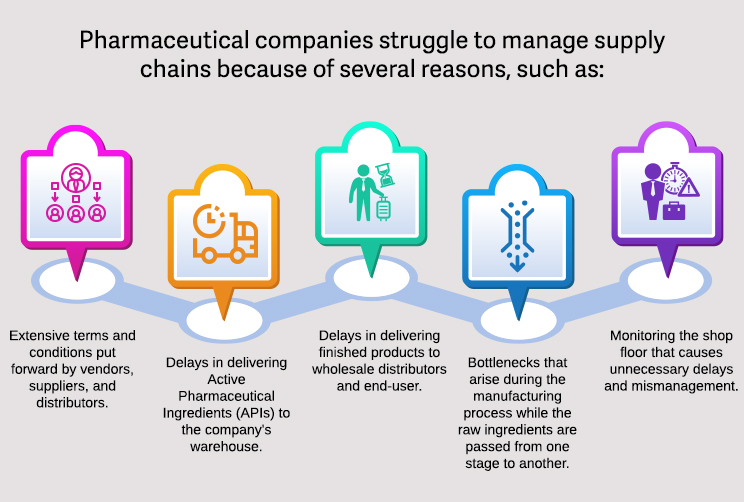

Pharmaceutical companies have been struggling to manage supply chains recently because of many reasons, such as:

a. Extensive terms and conditions put forward by vendors, suppliers, and distributors.

b. Delays in delivering Active Pharmaceutical Ingredients (APIs) to the company’s warehouse.

c. Delays in delivering finished products to wholesale distributors and end-user.

d. Bottlenecks that arise during the manufacturing process while the raw ingredients are passed from one stage to another.

e. Monitoring the shop floor that causes unnecessary delays and mismanagement.

IoT systems provide straightforward, convenient, and cost-effective solutions for these problems.

a. Blockchain-enabled Internet of Things devices have a feature called smart contracts that allow both parties to alter the terms and conditions with mutual consent.

b. Internet of Things systems send alerts to the vendors, suppliers, and distributors if the quantity of API in the pharma company’s warehouse falls below the predetermined threshold level.

c. IoT systems send real-time notifications to truck drivers who transport pharmaceutical products to wholesale distributors and end-users to reduce/eliminate the delays.

d. Internet of Things systems make the workflow more efficient by eliminating the redundancies that help speed up the process.

e. Small IoT chips can be attached to the finished pharmaceutical products in the inventory that helps track their real-time location.

2. Cybersecurity will increase significantly.

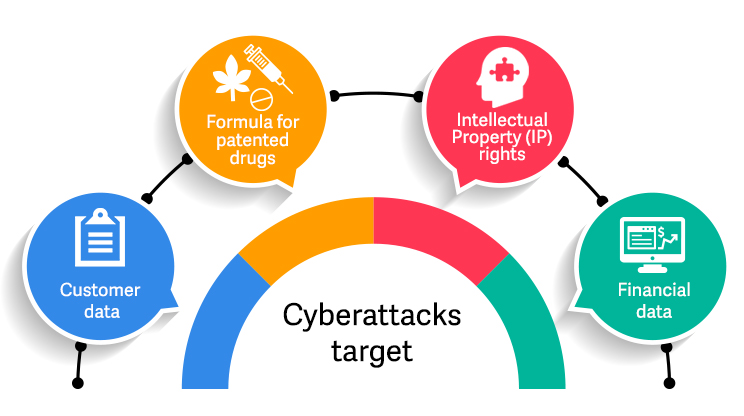

Cybersecurity has become a challenging question across all industries. Do you know that a cyberattack occurs every 39 seconds? Moreover, cybercrimes are no longer limited to DDoS attacks. Instead, they target:

b. Financial data

c. Intellectual Property (IP) rights

d. Formula for patented drugs

Today, cybercriminals are affecting areas such as government systems, nuclear power plants, weapons arsenal, and elections. Even the pharmaceutical industry isn’t safe from the onslaught of cybercrimes as hackers are stealing life-saving drug recipes and formulas and putting them on social media platforms and the dark web. It affects pharma businesses’ overall profits and revenues and makes them wonder whether they should invest a substantial amount of money, workforce, and machines in research and development. This can harm everyone, including patients, governments, and the pharma industry as a whole.

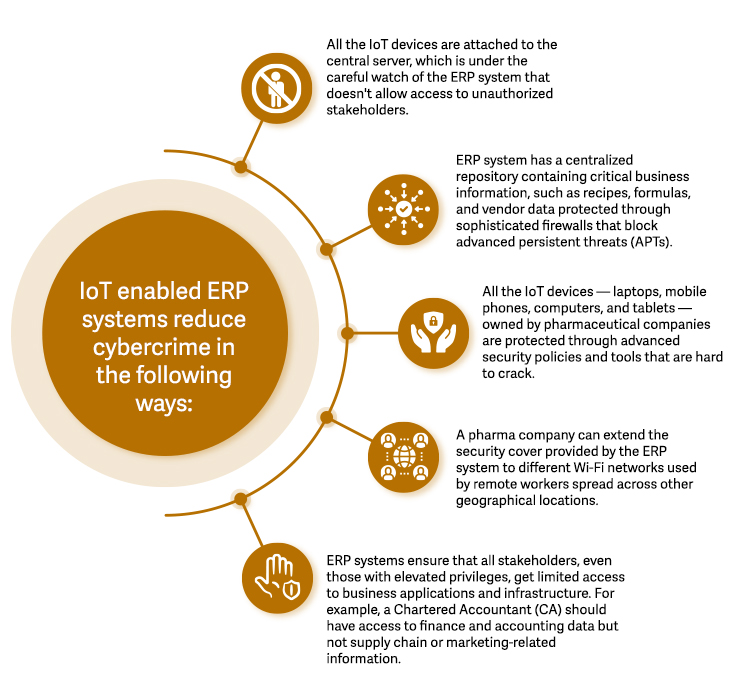

Internet of Things enabled ERP system can help curb the spread of cybercrimes in the following ways :

a. All the Internet of Things devices are attached to the central server, which is under the careful watch of the ERP system that doesn’t allow access to unauthorized stakeholders.

b. ERP system has a centralized repository containing critical business information, such as recipes, formulas, and vendor data protected through sophisticated firewalls that block advanced persistent threats (APTs).

c. All the IoT devices — laptops, mobile phones, computers, and tablets — owned by pharmaceutical companies are protected through advanced security policies and tools that are hard to crack.

d. A pharma company can extend the security cover provided by the ERP system to different Wi-Fi networks used by remote workers spread across other geographical locations.

e. ERP systems ensure that all stakeholders, even those with elevated privileges, get limited access to business applications and infrastructure. For example, a Chartered Accountant (CA) should have access to finance and accounting data but not supply chain or marketing-related information.

Also Read: ERP and Cybersecurity – What no one is talking about?

3. Government regulations will become easy to adhere to.

Do you know that India is the largest producer of generic drugs in the world? Statistics suggest that the Indian pharma industry will grow from USD 41 billion in 2021 to USD 120-130 billion in 2030. Similarly, the Indian biotechnology sector is also attempting to leapfrog the race when we talk about revenues. The report suggests that in 2019, this sector was pegged at USD 64 billion and is expected to swell to USD 150 billion in 2025.

But we must also focus on a few negative points. WHO reports that 10.5% of pharmaceutical drugs sold in low and middle-income countries, including India, are falsified and substandard. According to a report by the European Commission, 75% of global cases of Spurious, Falsely labeled, Falsified, and Counterfeit medicines (SFFC) originate from India.

Medical associations worldwide have made strict laws and regulations to control the influx of counterfeit medicines. Pharmaceutical organizations that fail to comply with mandatory rules and norms face bitter results. Sometimes, they may be heavily fined, while at other times, they might temporarily lose their operating licenses.

Internet of Things technology comes as a savior in such circumstances. The following points explain how:

a. Internet of Things sensors perform quality checks across numerous nodes to ensure that manufactured medicines and medical equipment are of the best quality and comply with the acceptable standards according to the government guidelines.

b. Packaging of Pharmaceutical drugs also attracts considerable penalties if not done according to pre-defined norms. IoT systems help package medicines effectively.

c. Internet of Things-enabled ERP systems send alerts and notifications regarding any new government circulars.

d. Internet of Things eliminate paperwork and reduce the potential margin of error.

e. Pharmaceutical companies can send reports, file taxes, and provide essential documents to the government instantly through IoT systems.

f. There are many international reputable organizations that create laws for pharma companies like the World Health Organization (WHO), Pan American Health Organization (PAHO), World Intellectual Property Organization (WIPO), International Conference on Harmonization (ICH), and World Trade Organization (WTO) for price control, manufacturing, marketing, drug product registration, research and development, and intellectual property protection rights. Internet of Things systems club different rules and regulations under few categories that make it easy to follow these guidelines and adhere to them.

Also Read: How is Sage X3 helping Pharmaceutical Manufacturing Industries?

Conclusion

The Indian pharma industry is experiencing explosive growth. India has already become the largest generic drug manufacturer globally and is setting new records with each passing day. Today, the whole world is looking forward to India for the supply of Covid-19 vaccines as it has the largest pharmaceutical manufacturing plants in the world. These reasons make it even more critical for Indian pharma companies to deploy Industry 4.0 technologies such as Internet of Things, artificial intelligence, machine learning, data analytics, cloud, and cybersecurity systems as they help streamline processes, organize workflows, create best quality products, maintain excellent relationships with third-party stakeholders, and adhere to government norms.

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Get in touch with us for more information. Click on this link, and one of our support agents will contact you immediately.

If you liked this article, don’t forget to share the link with your friends. Also, follow us on:

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.