Summary: The Food & Beverage (F&B) industry is recovering from the challenges raised by the covid-19 pandemic by upgrading its supply chain & logistics. IDC reports that 96% of F&B manufacturers will pay more attention to visibility, with 51% focusing on the end-to-end supply chain. In addition, it means that companies will look towards implementing food traceability systems into their businesses.

The pandemic exposed the rough edges of each industry. The significant challenges of the F&B industry that it brought to light were trade tensions, constantly changing government regulations and adverse environmental changes.

And what is the best solution?

Identifying the loopholes and increasing the transparency across the supply chain ecosystem.

According to the IDC report, 64% of F&B manufacturers believe that a decline in the supply chain flexibility and visibility will lead to significant issues in the future if not addressed immediately. Moreover, 46% consider supply chain visibility an essential parameter to measure the effectiveness of the supply chain risk management compared to 30% in 2018.

Companies need to improve their supply chain visibility to comply with government regulations to deliver quality to customers. But, at the same time, they must also enhance their industry competitiveness.

Initially, food traceability was crucial in the F&B industry for fulfilling regulatory compliances only. But today, when the significance of data has shot over the roof, and as technology has taken over everything, traceability has become a critical part of competitive differentiation and day-to-day business activity.

Here are five reasons why end-to-end traceability plays an essential role in the F&B industry:

1. Traceability enhances visibility

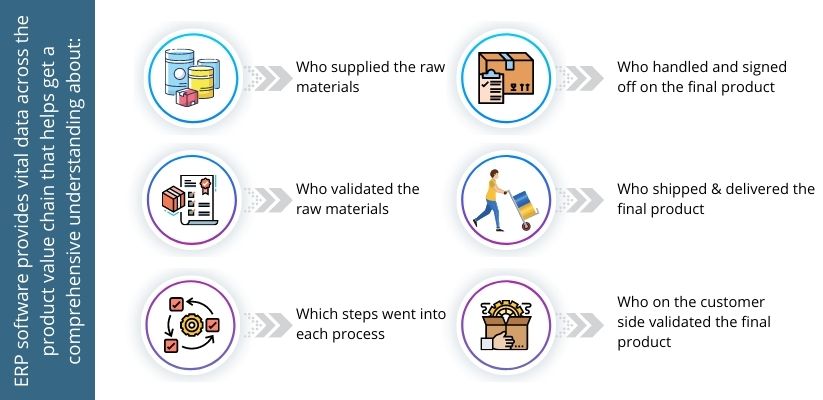

Food traceability allows F&B companies to track raw materials used in the production facilities. ERP systems, the best software for food traceability in India, enable tracing the entire supply chain and the exact location of the finished products in the warehouse.

-

Food traceability feature tracks progression.

ERP software tracks the movement of goods through the production facility, from procuring raw materials from vendors to manufacturing finished goods and then stocking them in the warehouse. You can see the sequence of steps involved in the production, the final location where each product is stored, who has worked upon them, and how long it will take for each activity to finish on the dashboard.

-

Food traceability feature focuses on authentication.

The food traceability feature of ERP software allows F&B companies to identify products through supply-chain records — purchase order number and certification of origin.

Two essential criteria for measuring food traceability are:

- Critical data from manufacturers, vendors, suppliers and distributors are recorded effectively.

- Disparate systems that record and maintain business data are integrated and connected effectively.

The research conducted by IDC through 140 medium to large-sized companies tells that most process manufacturers can significantly improve their functions through automated traceability.

Also Read: ERP for Food Processing Industry

2. Traceability in the food industry keeps you compliant with government regulations.

An automation control system can substantially enhance traceability by collecting data across each level and storing it in a central Manufacturing Operations Management (MOM) or Manufacturing Execution System (MES).

In MES, small sensors form the first level of automation that collect and analyze information, such as timestamp, the supplier of the product, and the operator that handles the product. These data points are then converted into production data that the plant manager can review at the desired time.

The MOM software monitors and guides operators ensuring they perform tasks appropriately. It helps avoid non-conformances and deviations, allowing businesses to perform operations quickly and efficiently.

Further, critical data, including test results, material lots, quantities, and process parameters, are gathered along the process, ensuring backward and forward traceability.

3. Build robust customer relationships through digital food traceability.

Do you remember the horsemeat scandal in 2013? The food that was advertised to contain beef contained improperly declared or undeclared horsemeat. The F&B industry gathered immense flak for this negligence on various media platforms.

Today, customers progressively demand better product safety rules and regulations. As a result, regulatory bodies have also launched new guidelines that require more detailed information from F&B manufacturers than ever before.

Full-scale traceability features protect consumer health and your company’s reputation in the event of a product recall. It identifies any product issues early on by monitoring what gets manufactured for consumers and provides increased visibility to manufacturers. End-to-end value chain traceability also allows establishing an excellent reputation in front of retailers. It shows that you are a trustworthy supplier and would go out of the way to provide crucial information that today’s customers crave. Also, remember that if you fail to comply with the government-mandated requirements, you may get into legal trouble that may tarnish your brand value in the long run.

Digital food traceability will significantly improve your brand value as it will allow you to highlight that you acquire raw materials from ethical and environmentally sustainable sources.

Ella’s kitchen, a UK-based organic baby-food maker, is a prime example that shows full traceability plays a substantial role in establishing your F&B brand as a trusted name in the market.

4. Use ERP software to comply with top-notch food traceability standards.

Enterprise Resource Planning (ERP) software enables F&B companies to gain end-to-end traceability. You can download the entire product history — from raw materials to finished goods. In addition, ERP software allows you to track and account multi-company, multi-site, and multi-legislative product journeys.

With so much data in hand, you can optimize and improve the supply chain across the following areas:

- Compliance

- Quality control

- Sustainability initiatives to meet the market needs

- Planning and scheduling

5. Food traceability in India will enable you to implement digital transformation.

The backbone of effective traceability is having access to real-time and accurate data.

Now ask an essential question to yourself: Does each department in your company has a separate information silo? If yes, then food traceability is a distant dream for you.

The bedrock of digital transformation depends on creating a unified information database that allows business stakeholders to create, edit, access, and share crucial information from anywhere, anytime, and through any device. And this is where cloud-enabled ERP software comes into the picture.

They enable F&B companies to implement end-to-end traceability infrastructure, optimize supply chain & logistics, fulfill documentation and quality requirements, and comply with government-mandated norms quickly and efficiently.

Implementing ERP systems will be your best bet. They will allow cutting operational expenses, perform repetitive and mechanical tasks immediately, and increase revenues in the long run.

STAY UPDATED

Subscribe To Our Newsletter

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.