What is Cross Docking?

Cross Docking is a logistical model that involves setting up dedicated docking terminals to facilitate a steady stream of customer-ready goods by directly unloading them from the inbound delivery vehicles and loading them onto outbound vehicles, thereby eliminating the need for a separate warehouse storage & inventory handling.

Cross Docking is an exceptional solution to increased warehouse storage costs and bottlenecks in the delivery workflow. Businesses operating in a diverse range of industries use ERP Software to adopt this logistical model and save themselves from the hassle of manual labor work in the logistical procedure. Not having to store goods in a warehouse lowers operational delays in the logistical processes, saves storage costs, reduces the risk of potential damages, and ensures timely fulfillment of the customer’s orders.

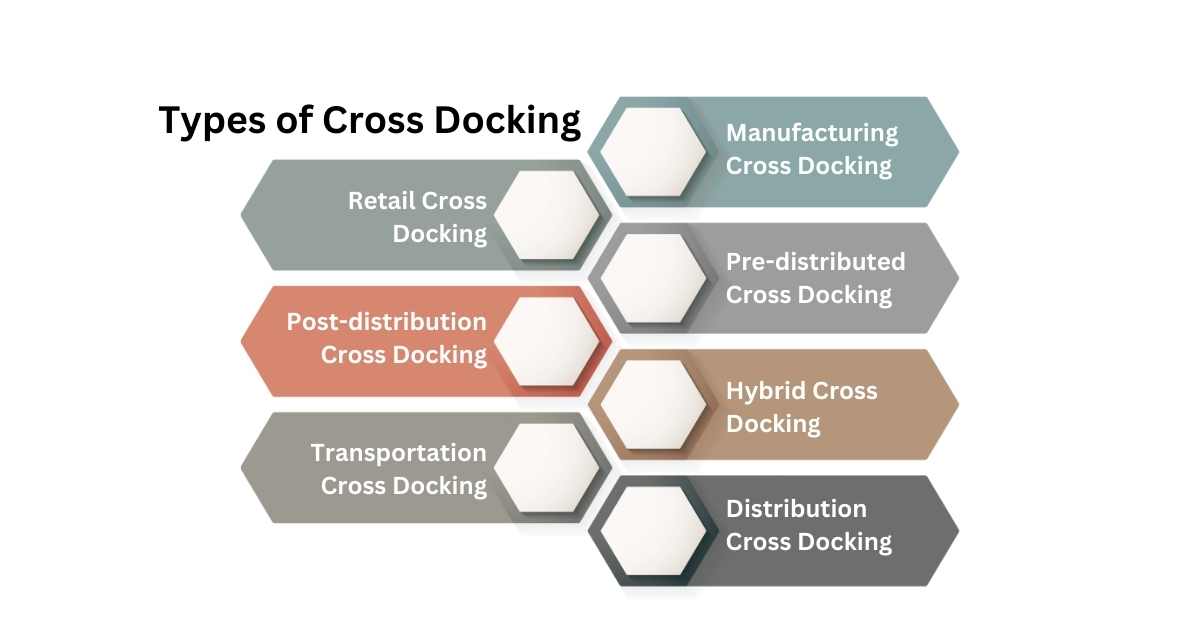

What are the Different Types of Cross Docking?

1. Manufacturing Cross Docking

Here, the materials are procured from multiple suppliers and they are immediately transported to the manufacturing plant with a central docking system. This ensures the continuation of manufacturing operations and eliminates shortages.

2. Retail Cross Docking

A retail company establishes a central docking system to distribute goods received from the manufacturer into different retail outlets as per their requirements. They use a dedicated Inventory Management System to reduce inventory holding costs.

3. Pre-distribution Cross Docking

Pre-distributed Cross Docking involves sorting, packaging, and labeling products before they are sent to the distribution centers. Businesses with multiple distribution points prefer this method to facilitate last-mile delivery.

4. Post-distribution Cross Docking

Post-distribution Cross Docking re-routes goods at the central docking system. It provides more flexibility than the pre-distributed one and allows effectively addressing product recalls & demand spikes.

5. Hybrid Cross Docking

This type of Cross Docking is a mix of both the Pre-distributed and Consolidated Cross Docking. It is primarily used to meet specific logistical requirements for complex supply chains. Much like any other type, Hybrid Cross Docking has its own drawbacks.

6. Transportation Cross Docking

Transportation Cross Docking consolidates smaller loads from multiple suppliers into larger shipments with the aim of lowering storage time, reducing freight costs, and improving logistical efficiency.

7. Distribution Cross Docking

In this type of docking system, a single docking hub is used to collect products received from multiple suppliers. This docking hub sorts and immediately dispatches the goods to a variety of retail chains. This type of docking system is preferred when the products are of diverse nature rather than homogeneous.

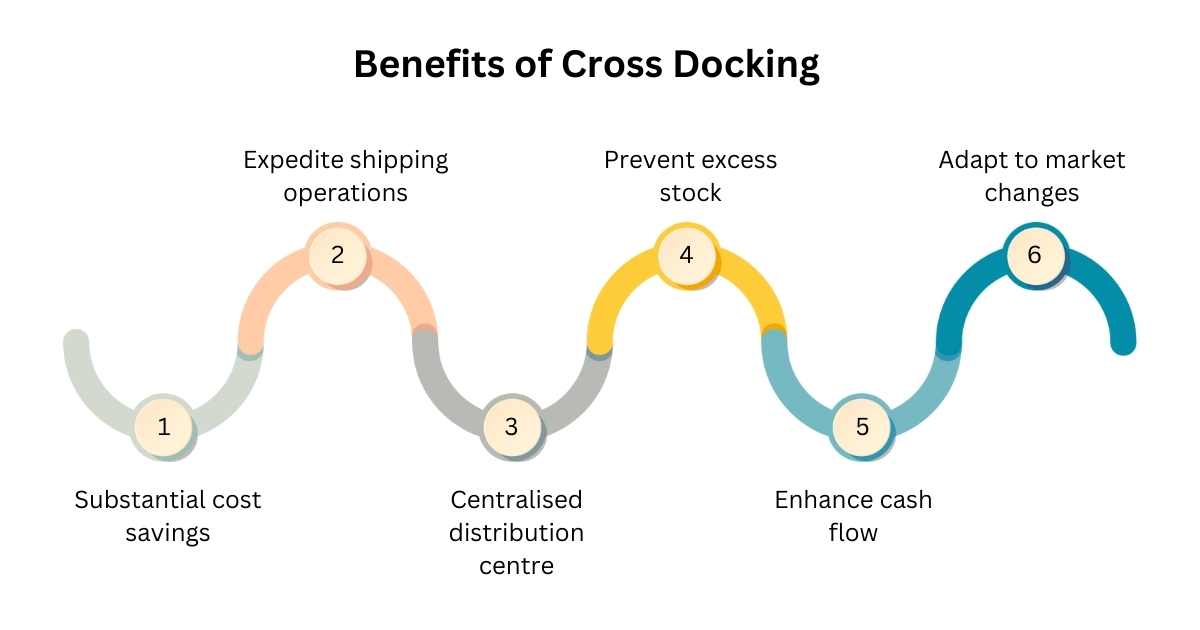

Key Benefits of Adopting Cross Docking Model

Businesses across the world are realizing the advantages of Cross Docking in terms of faster product delivery, increased efficiency, and reductions in handling costs. Combining this proven logistical model with ERP implementation will yield many benefits:

1. Substantial Cost Savings

Many businesses, especially the small and medium ones, do not have large warehouse facilities to store goods. Thanks to Cross Docking, they can benefit from substantial cost savings and lower transportation costs.

2. Expedite Shipping Operations

Traditional warehouse processes are not only costly but also time-consuming. In today’s time when businesses are under tremendous pressure to deliver goods on time, Cross Docking expedites the shipping process and enhances customer experience.

3. Centralized Distribution Center

As we’ve seen in the Cross Docking meaning, it makes it simple and time-efficient to handle goods in a central place. It brings transparency to the entire logistical process.

4. Prevent Excess Stock

Excess stock is challenging for businesses because it increases the storage cost of your inventory and ties up excess capital for a longer period. Thanks to Cross Docking model, you can prevent such situations.

5. Enhance Cash Flow

A positive cash flow in the Cash Flow Statement acts as a buffer against potential challenges your business may face in the future. Cross Docking frees up business capital tied up to excess inventory. With more cash readily available at hand, decision-makers will be in a better position to cover the company’s financial obligations and reinvest it in meaningful ways to promote growth.

6. Adapt to Market Changes

Market trends are dynamic. Businesses have to stay agile to respond to new changes and capture new markets. Cross Docking helps you adapt swiftly to new trends & patterns, and meet customer’s requirements.

Limitations of Cross Docking Model

Much like any other model, Cross Docking is not free from limitations.

1. Operational Complexity

Cross Docking is not simple. It requires a high level of coordination among different business elements at cross-dock facilities.

2. Risk of Potential Disruptions

Cross Docking requires a higher degree of coordination and accuracy. There is a risk of potential disruptions in the logistical operations due to a mismatch in the timing of inbound and outbound shipments.

3. Capital-intensive Activity

Cross Docking is a capital-intensive activity. Establishing various specialized terminals will require a significant amount of capital.

4. Resistance to Change

Some suppliers may prefer the traditional way of warehousing. For smooth operations at all levels, there is a need for collaboration between all the stakeholders.

Difference Between Cross Docking and Traditional Warehousing Models

Now, let’s understand in simple ways how Cross Docking differs from the traditional model of warehousing.

| Cross Docking | Traditional Warehousing | |

| I. Definition | Cross Docking is a logistical strategy that uses dedicated docking terminals to avoid time, inconvenience, manual labor work, and cost associated with traditional warehousing. | Traditional Warehousing is a logistical strategy that caters to the stock-holding needs of businesses until the goods are ready to dispatch to the next destination |

| II. Purpose | Facilitate quick distribution of goods with little to no holding period | Facilitate storage of goods until they are prepared for further transportation |

| III. Operational Complexity | Highly complex (Requires cooperation and coordination between inbound & outbound shipments) | Less complex |

| IV. Inventory Storage Time | Minimal (Typically, less than 24 hours | Extended (Typically, a few days to a few months) |

| V. Lead Time | Lower lead time | Higher lead time |

| VI. Cost Implications | Cost-effective | Higher inventory storage costs |

| VII. Level of Efficiency | Highly efficient | Less efficient |

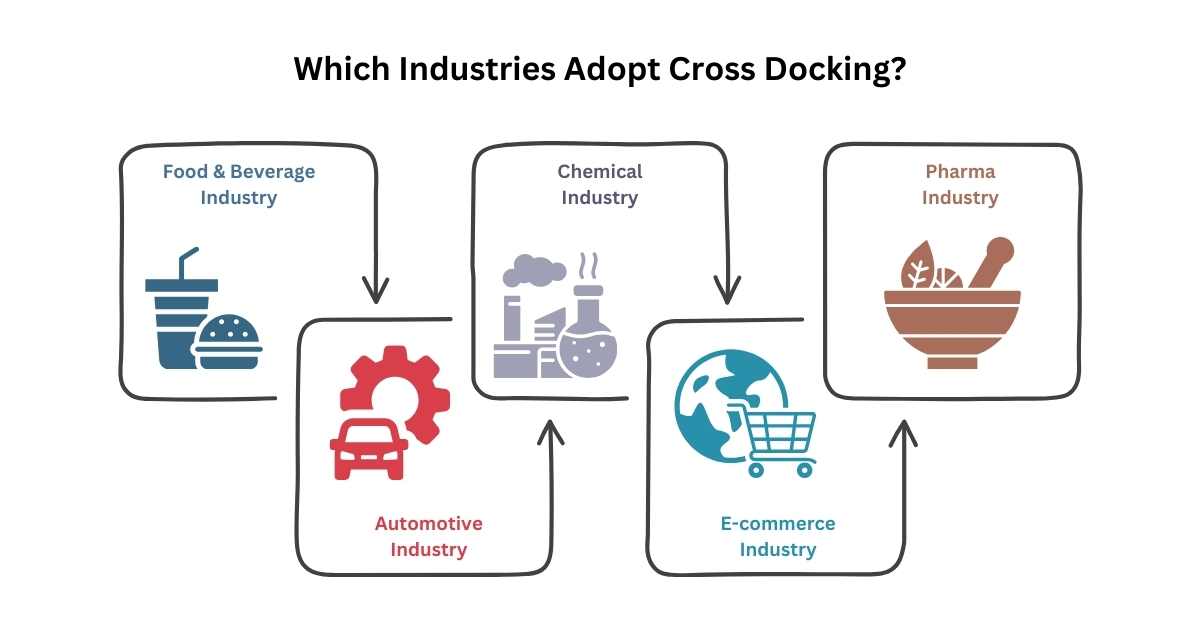

Which Industries Adopt Cross Docking the Most?

The new logistical model is gaining popularity among different industries due to the immense benefits it offers. Here are its early adopters:

1. Food & Beverage Industry

The food & beverage industry mainly deals with perishable products that have shorter life spans. It uses ERP for Food Industry to handle a high volume of perishable items and avoid storing them for extended periods.

2. Automotive Industry

The automotive industry is considered to be highly competitive in nature. Companies operating in the automotive industry use Automotive ERP to efficiently manage Cross Docking operations.

3. Chemical Industry

The chemical industry is an excellent example of Cross Docking. Since chemicals cannot be unloaded into warehouses, companies use specialized ERP for Chemical Industry to reduce the risk of potential damage.

4. E-commerce Industry

Cross Docking helps the e-commerce industry prioritize speed and logistical efficiency amid various flash sales, rebates, and promotional campaigns.

5. Pharma Industry

Pharmaceutical companies conduct demand forecasting for their products with dedicated Pharma ERP Software. This helps them make intelligent shipment routing decisions.

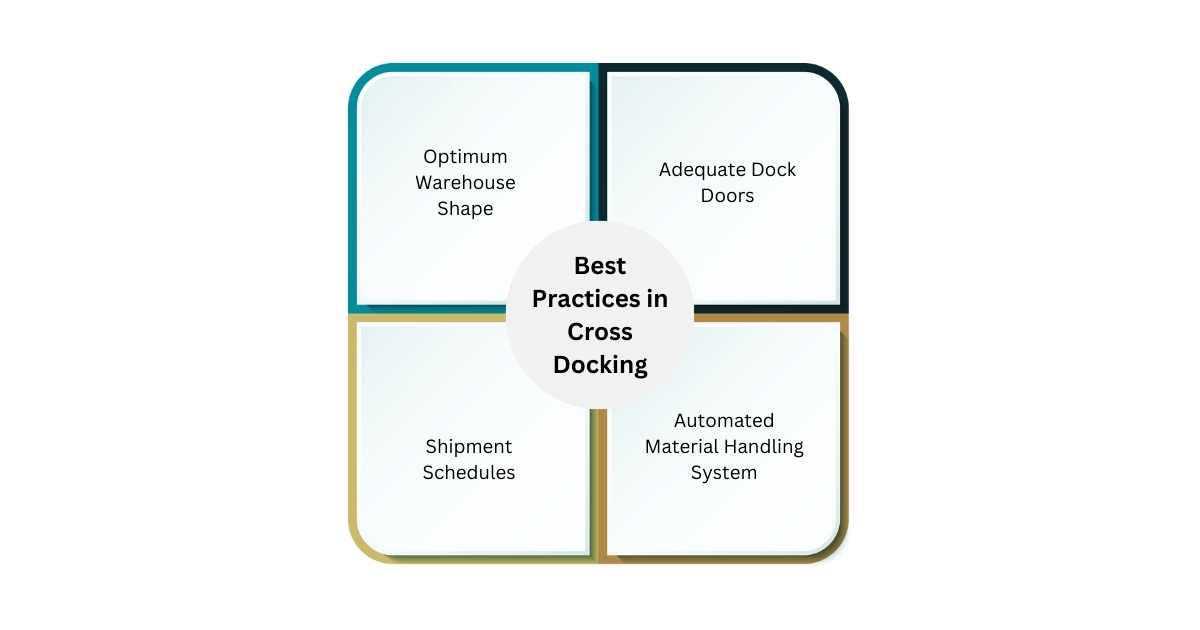

Best Practices in Cross Docking

Merely establishing a central docking system isn’t enough. We’ve compiled some best practices so that you get the optimum results.

1. Optimum Warehouse Shape

A warehouse in good shape will enable the free movement of goods with minimal disruptions. Less disruption translates into increased efficiency and faster order delivery.

2. Adequate Dock Doors

Dock doors are often neglected yet very important element. Make sure that you have enough dock doors and that they are not inadequate in size. Doors that are too small in size can lead to hurdles.

3. Shipment Schedules

Keeping a balance between the inbound and outbound shipments will help you avoid congestion at the dock.

4. Automated Material Handling System

Leverage the new technology and tools to automate the movement of inbound and outbound goods. Think of implementing the Best ERP Software in India that can automate both the FIFO method and LIFO method, depending on your choice.

Make Your Business Thrive with Sage X3

Cross Docking is adopted in various industries across India to benefit from the speed, efficiency, and agility required for logistical operations. ERP empowers companies with coordination, accuracy, and operational efficiency required for the smooth execution of Cross Docking processes, and ensures timely delivery of goods to the final consumer.

Sage X3 is a ready-fit solution for modern businesses that are looking to streamline the entire spectrum of logistical operations, gain cross-functional efficiency, and elevate order fulfillment procedures. It’s a best-in-class tool that serves as the central hub of information to manage goods coming in from multiple suppliers, effectively handle risks, and make proactive decisions.

FAQs

1. What is Cross Docking Meaning in the Context of Logistical Operations?

Cross Docking is a model of supply chain that relies on the swift transfer of goods from inbound vehicles to outbound vehicles, thereby reducing reliance on traditional warehouse facilities. The objective of adopting this model is to fast-track the customer fulfillment process and ensure products reach the final delivery center with minimal or no delays.

2. How is Cross Docking Different from Warehousing?

Warehousing is a traditional method of distribution whereas Cross Docking is a modern way of handling goods. In warehousing, when goods arrive at a warehouse facility, they are unloaded and stored for a few days weeks, or months. This is a time-consuming procedure.

In contrast, whenever goods enter the Cross Docking facility, they are quickly transferred to outbound shipments for immediate delivery. Not only does this save time & money but also results in higher efficiency and better customer experience.

3. What Kind of Warehouses Are Used for Cross Docking?

There are no special types of warehouses designed solely for Cross Docking. Both the traditional warehouses and modern distribution centers are useful. Many e-commerce giants use their dedicated fulfillment centers to swiftly transfer goods to the final delivery centers. This helps them gain a competitive advantage and they are in a better position to quickly fulfill customer orders.

4. Why are Companies Moving from Traditional Distribution Centers to Cross Docking?

Many companies across India and around the world are moving from traditional Warehouse Distribution Centers to Cross Docking. Here are the reasons:

- Facilitate quick movement of food and other perishable items

- Supply Chain Management tools reduce bottlenecks in the supply chain and improve inventory turnover

- Reduce the cost of product distribution and increase profit margins

- Eliminate the need for a dedicated warehouse storage

- Get rid of manual labor work and re-packaging activities

5. What are the Processes Involved in the Cross Docking?

The Cross Docking activity includes various processes. Some of them are as under:

- Shipment Receival: The goods are received in the central docking system through road or rail freight.

- Unloading Goods: The goods are unloaded from the incoming truck or rail containers.

- Product Sorting: The goods are sorted based on their characteristics and final delivery destination.

- Quality Checks: The Quality Assurance stage involves checking your goods for their quality and potential damage during transportation.

- Outbound Transfer: The goods are transferred to the outgoing shipping dock. There is no or minimal storage of goods.

- Loading for Dispatch: The goods are finally loaded onto an outbound road or rail freight for delivery to the final delivery station.

- Final Dispatch: The road or rail freight carrying the goods departs from the location.

6. How Does the Technology Transform Cross Docking?

Modern technology is revolutionizing the way logistical operations were handled traditionally. For example. the use of ERP Application has allowed businesses to benefit from automation & coordination, and gain access to real-time information through custom reports & personalized dashboards. Its Warehouse Management System helps you streamline order processing and control the movement of goods. There are other modules of ERP that support different business operations from production, sales, supply chain, and financials, among others.