What is AI in Supply Chain?

AI in Supply Chain refers to the use of advanced machine learning and artificial intelligence algorithms to facilitate insightful data-driven decisions, mitigate potential risks & disruptions, and optimize the workflow.

Businesses are integrating AI with their dedicated ERP Software to take advantage of the GenAI models that bring transformative changes into the supply chain processes, reduce costs, and reduce waste.

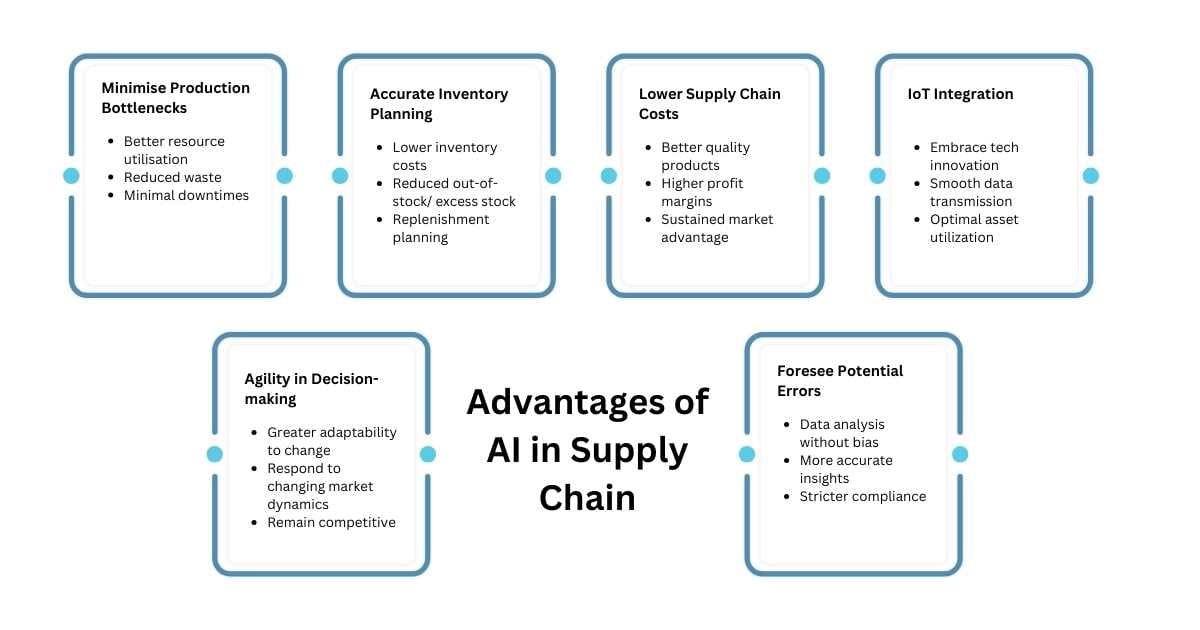

Advantages of AI in Supply Chain Management

If you’re wondering how your business would benefit from AI integration into the supply chain, here’s a glimpse of the endless possibilities:

1. Minimize Production Bottlenecks

AI provides end-to-end visibility throughout the production cycle. It helps you efficiently manage production resources, plan production activity, assign the right person for the right job, improve coordination across different elements (such as human, machinery, and fixed assets), and achieve optimal production efficiency.

2. Accurate Inventory Planning

In today’s fast-paced world, businesses must consistently monitor new market trends and changing consumer interests to effectively manage their inventory. Integrating AI with an Inventory Management System provides businesses access to manage inventory using the FIFO method and LIFO method, in addition to accurately predicting demand for their products, preventing excess stock, and reducing inventory storage costs.

3. Reduced Supply Chain Costs

Businesses often incur significant logistical expenditures while traveling goods from one location to another. Using AI in supply chain management helps optimize delivery routes, reduce travel distances, and minimize fuel consumption, all of which collectively result in lower supply chain costs.

4. IoT Integration

Integrating AI in supply chain management enables real-time transmission of information about flight changes, and makes the entire stressful travel experience enjoyable. Businesses use Internet of Things (IoT) devices to track cargo or shipment, identify machine faults, and process data instantly.

5. Agility in Decision-making

One of the best things about AI is its ability to process large & complex datasets within seconds and derive meaningful conclusions. With AI, decision-makers can gain better visibility into past market trends and sales reports so that they can make strong & informed decisions. Ultimately, fast & accurate decision-making plays a significant part in your business’s growth & success.

6. Foresee Potential Errors

AI in supply chain helps businesses reduce the likelihood of human errors in the supply chain process. It empowers your business with strategic algorithms for predictive analysis, identification of variances & flaws in the data, and course-corrective measures. Overall, it prepares your business to deal with potential risks and uncertainties.

Disadvantages of AI in Supply Chain Management

While AI can empower various aspects of the supply chain process, there are certain disadvantages as well.

1. Huge Upfront Costs

Adopting ML and AI models requires huge computing power, high-frequency Internet bandwidth, powerful resources, and dedicated frameworks, all of which cost a higher upfront investment.

2. Integration Complexities

If you’re using an obsolete legacy tool, chances are that it may not support AI altogether. You will need a dedicated & specialized Best ERP Software in India for seamless integration.

3. Lack of Quality Data

The outcomes of your AI analysis largely depend on the quality of the user data, and the efficiency of the AI models. A low-quality, incomplete, or inaccurate data can result in false predictions, unreliability in the effectiveness of the business performance, and a major hurdle in quality assurance.

4. Job Displacement

AI can perform various tasks that were previously performed by humans with greater efficiency and lower potential for errors. This can make certain job roles redundant and replace human workers.

What are the Steps for Integrating AI in Supply Chain?

Now, let’s discuss the step-by-step procedure to integrate AI in supply chain management activities of your company.

1. Assess Logistical Network

Analyze your current logistical network, and perform a thorough SWOT Analysis (Strengths Weaknesses Opportunities Threats Analysis). A comprehensive SWOT Analysis will help you understand your company’s current market position and determine the well-performing areas and the areas that require immediate attention.

2. Prioritize Supply Chain Issues

Integrating AI with Supply Chain Management Tools offers numerous benefits for businesses. However, it’s important to prioritize your supply chain issues and focus on the most important ones on a priority basis. This will help you align your future course of action with your short & long-term business objectives.

3. Explore Alternate Solutions

Explore different alternate solutions to your supply chain issues and select the one that best suits your current needs, business size & type, and the nature of your business activities. Choosing the best solution will help you maximize the returns.

4. AI Deployment

At this stage, start deploying the AI with your ERP Application throughout the supply chain activities across your organization. If you’ve multiple branches, consider a phased deployment to avoid large-scale disruptions. Be sure to provide extensive training to your staff, and help them with any queries & technical challenges they might go through.

5. Employee Training

Employee training is one of the most important parts of the AI deployment. A well-trained employee will be in a better position to effectively use the technology for the greater benefit of the organization, and handle technical complexities. Moreover, it will reduce the potential for human errors.

6. Post-deployment Monitoring

This is the final stage that involves keeping an eagle’s eye on the new deployment for early detection and fixing of potential bugs. You may also encourage employees to report any issues they might be facing with the new system to contribute to building a robust AI framework.

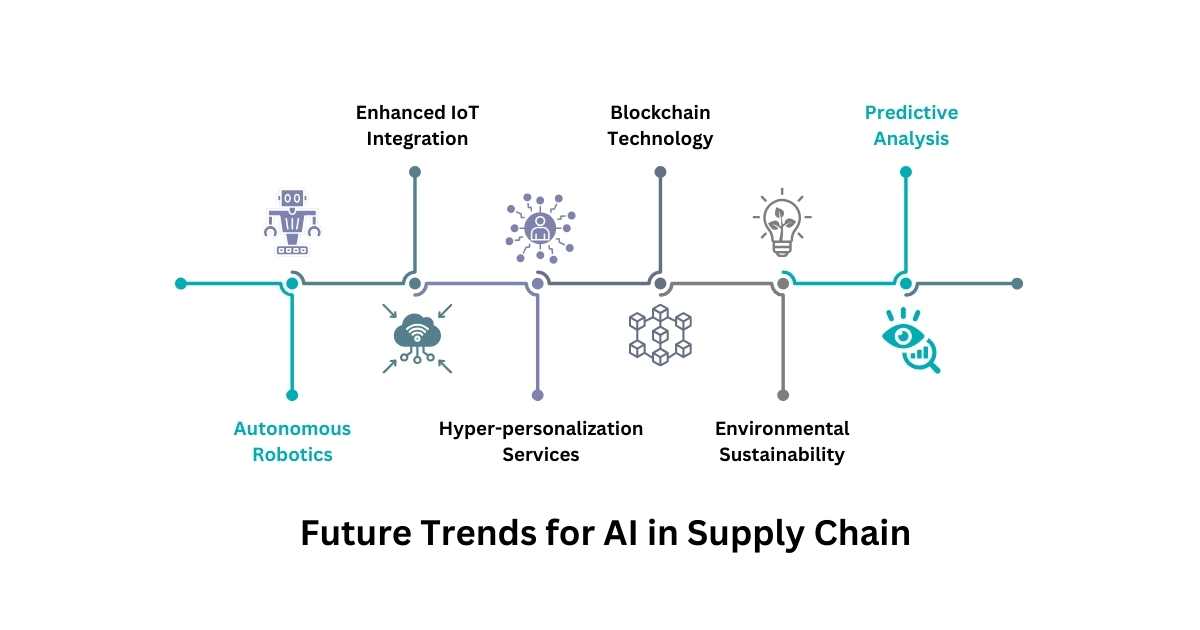

Future Trends for AI in Supply Chain Management

Artificial Intelligence has immense transformational power. It is revolutionizing the supply chain activities and empowering businesses with cutting-edge technology.

1. Enhanced IoT Integration

AI in supply chain improves real-time tracking and monitoring with the IoT sensors to find fast delivery routes, reduce delays, and enhance customer satisfaction.

2. Autonomous Robotics

AI-powered robots are increasingly replacing human labor in hazardous activities. Moreover, it assists them with other operations such as sorting, picking, and packaging products.

3. Hyper-personalization Services

AI’s unique ability to analyze thousands of lines of data within seconds helps businesses provide customized recommendations to their customers and offer customer-centric products.

4. Blockchain Technology

Integrating AI with Blockchain allows businesses to reduce instances of fraud & counterfeiting, optimize data transactions, and provide a secure sharing of knowledge.

5. Environmental Sustainability

The use of AI supply chain management helps businesses identify potential opportunities in recycling waste and filtering recyclable & non-recyclable waste to reduce potential impact on the environment.

6. Predictive Analysis

AI assists with improving data integrity, effective data management, analyzing qualitative & quantitive data, leveraging predictive analytics, and identifying & mitigating risks.

Wrapping Up…

Artificial Intelligence (AI) is shaking up the modern business landscape, including Supply Chain activities. The rapid advancement in AI and the integration of AI in supply chain management are poised to offer unprecedented opportunities to businesses of all sizes and types across the world.

Sage X3 empowers your business with a solid framework and sophisticated algorithms to process large datasets, perform extensive data visualization, and gain a dynamic view of your business performance. It drives your business forward by profoundly transforming various critical processes in supply chain management. From optimizing production capacity, reducing supply chain bottlenecks, supercharging efficiency, and accurately predicting risks, to automating vendor negotiation, it lets you harness the power of cutting-edge algorithms.

FAQs

1. What is GenAI in the Supply Chain?

Generative Artificial Intelligence (GenAI) is an AI system capable of generating texts, images, and videos that mimic human-like creativity. Many Indian businesses are integrating Artificial Intelligence and Supply Chain Management to gain actionable insights for smart, fast, and coherent decision-making.

2. What are Some Examples of AI in Supply Chain?

Integrating AI in supply chain has become a necessity for many businesses around the world to proactively face various challenges. Here are some examples of AI in supply chain:

- Vorto: Vorto is a company based in the US that effectively uses AI to reduce carbon emissions during supply chain operations, automate various processes, and optimize delivery time.

- Echo Global Logistics: It is another Illinois-based company that uses AI supply chain management for improving shipping performance, and automating rate negotiation, shipment execution & compliance.

- Symbotic: Symbotic was founded in 2007. Today, it has mastered the art of using Machine Learning & Artificial Intelligence to optimize its inventory levels and increase operational flow.

- FedEx: FedEx is a multinational transportation company that uses AI-powered robots for autonomous truck loading and fulfilling end-point customer deliveries.

3. How Does the AI Help Tackle Supply Chain Disruptions?

The integration between Artificial Intelligence and Supply Chain Management helps you tackle supply chain disruptions and various other problems experienced by your organization:

- Promptly identify a supply chain disruption

- Develop a contingency plan to effectively deal with supply chain risks

- Make effective use of modern technology such as data analytics, IoT sensors, blockchains, and Industry 4.0

- Compare the effectiveness of the previously deployed response strategies

- Assess the impact of sudden market changes through a combination of technologies such as AI and Business Intelligence Tools

- Develop effective strategies to respond to sudden market changes

4. What Could be the Role of AI in Supply Chain Management in the Future?

Experts predict a transformative role of AI in supply chain management even in the future. The integration between Artificial Intelligence and Supply Chain Management is evolving. It will continue to evolve even in the future. As the existing AI models keep evolving with new pattern detection algorithms and reasoning skills, they will help optimize supply chain management, reduce supply chain disruptions, and effectively handle never-experienced supply chain scenarios.

5. How Does AI Enhance Customer Experience?

Integrating artificial intelligence with your existing CRM System will help you improve the customer experience, gauge the quality of the leads, and improve revenue.

- Anticipate Customer Demands: AI helps businesses gain visibility into new market trends & analyze customer buying patterns to anticipate & fulfill demand for their products.

- Virtual Assistants: Customers can chat with AI-powered virtual agents who provide personalized services and timely and accurate resolutions to their issues.

- Product Recommendations: AI-powered support agents analyze business leads and provide personalized recommendations to drive sales, and find new cross-sales opportunities.

- Consistency in Quality: One of the best things about AI it works round-the-clock with the same consistency in the quality of customer service.