Analysing and calculating the amount a company spends for the business is a major part of accountancy. Absorption cost accounting is an accounting method to help the business in determining the total value of the inventory. It is crucial for the business to understand its value and how to use it. In this blog, let’s learn more about its advantages, disadvantages and how it works.

What is Absorption costing?

Absorption costing is also known as full costing. It is an accounting method to value inventory and includes factors such as the cost of the materials, direct labour and also variable and fixed manufacturing overhead costs.

In the absorption costing method, anything that is a direct cost used to manufacture a finished product is included. It also encompasses fixed overhead costs which is a segment of product cost. Product manufacturing also includes other costs such as employee wages(physical labour involved in the making of the product), the raw materials used in the production process and the entire overhead costs used in the production(utility costs).

Components of Absorption costing

The following costs comprise the overall absorption costing and it goes into the product costs. They are listed below —

- Direct material (DM)

- Direct labour (DL)

- Variable manufacturing overhead (VMOH)

- Fixed manufacturing overhead (FMO)

The period cost comes under the absorption costing which is listed below. And it does not go with the cost of the product, rather they are expensed in the period that occurred.

- Variable selling and administrative

- Fixed selling and administrative

Direct costs are those directly related to the expenses of a particular product or a service. The costs include expenses related to raw materials, labour and any other direct expenses that are incurred during the processes.

Indirect costs are also expenses, but they cannot be directly traced to a particular product or a service. These expenses are also known as overhead costs. Utilities, rent and insurance are included as indirect costs. It is assigned to a product or service depending on any product or service such as the total number of units produced or the number of direct labour hours needed to manufacture the product.

As mentioned earlier, the absorption costing includes both direct and indirect costs. So it means that the cost per unit includes both direct and indirect expenses of that unit. The formula for absorption costing is given below. Here the total production costs are divided by the number of units produced to determine the expense of each unit.

Absorption Cost = (Direct labour costs + Direct material costs + Variable manufacturing overhead costs + Fixed manufacturing overhead) / Number of units produced.

Also Read : Inventory Valuation with Multiple Costing Methods

Types of Absorption Costing

Absorption costing can be divided into two types : Full absorption costing and Partial absorption costing.

→ Full absorption costing – This is related to all the expenses associated with manufacturing a product or providing a service. And it includes fixed manufacturing overhead and variable manufacturing overhead costs. In this type, the total expense of a product or service is either absorbed or spread out, over the manufactured units. The cost per unit manufactured comprises both fixed and variable costs related to that particular unit.

→ Partial absorption costing – Here, only some of the costs are included with manufacturing a product or providing a service. And only a small portion of fixed assets are included in the cost of per unit produced. Plus, the remaining fixed overhead costs are regarded as the period cost and are expensed in the period in which it is incurred.

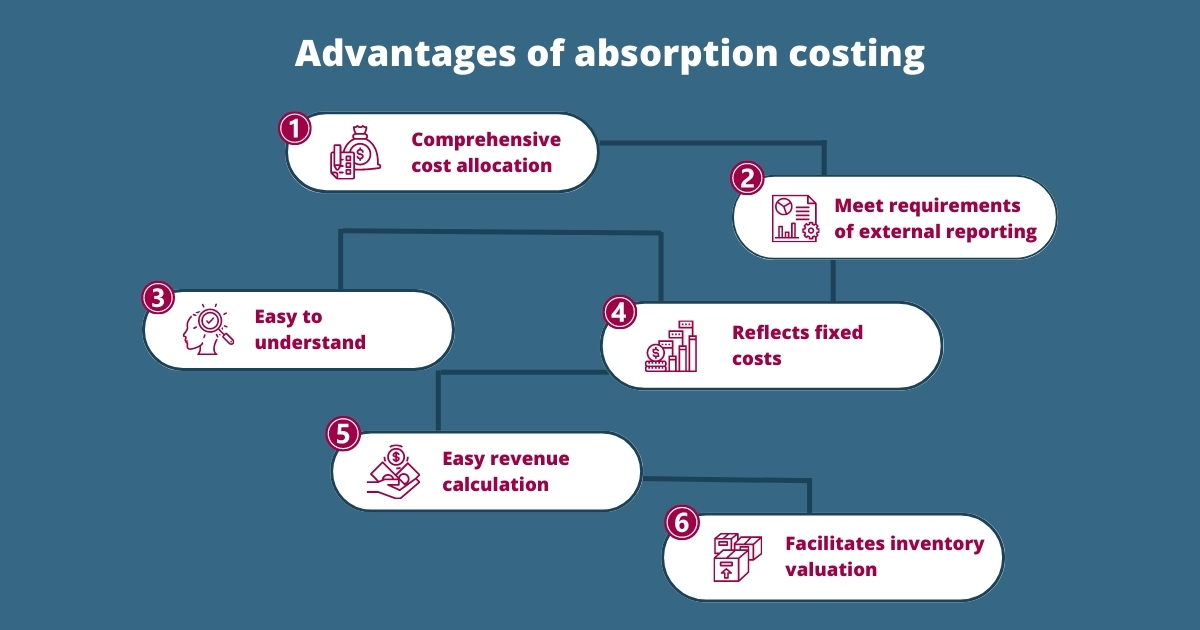

Advantages of Absorption Costing

Absorption costing is one of the methods of costing to determine the value of the inventory. Here, it gives more accurate accounting for the ending inventory as the cost associated with it are associated with the full cost of the inventory. Enumerated below are some of its benefits.

1. Comprehensive cost allocation

Absorption costing covers all product costs, which include both variable and fixed costs. So it offers a more accurate reflection of the total cost of manufacturing a product or providing a service that allows better decision-making.

2. Meet requirements of external reporting

Absorption costing is vastly accepted for external reporting purposes, such as financial statements. Regulatory bodies require and accept absorption costing for compliance and transparency.

3. Easy to understand

It is a straightforward method which is simpler and makes it accessible to a wide range of businesses, despite their size or complexity. The absorption costing method assigns all costs to units produced, providing a clear view of the total costs per unit.

4. Reflects fixed costs

For the absorption costing method, fixed costs are necessary for production. It allocates fixed costs to units produced and ensures that these costs are accounted for and absorbed by the products. So it allows a just distribution of costs across the product range.

5. Easy revenue calculation

In the absorption costing method, the variable and fixed costs are incorporated to facilitate accurate profit calculation. All the expenses are allocated to the units produced and the profit derived from each unit comprises an equal share of fixed costs. The absorption costing method provides a more detailed view of the profitability of products and services.

6. Facilitates inventory valuation

A portion of fixed manufacturing overhead costs to the ending inventory. And this method aligns with the general accounting principles by providing a more accurate value of the inventory. So Including fixed costs in the inventory value, absorption costing can reflect the total cost of production.

Disadvantages of absorption costing

- If there are major changes in the production volume, absorption costing can lead to distorted cost data.

- It may not provide sufficient information for the decision-making process, unlike other methods such as variables.

- It comprises fixed overhead costs that do not differ from the production volume. So, it is possible that the absorption costing method may not accurately reflect the incremental costs related to manufacturing an additional unit of a product.

Conclusion

The absorption costing method comprises all manufacturing costs – fixed and variable costs, in the product cost. It is also referred to as full costing or full absorption costing. It is used to determine the cost of goods sold and ending inventory balances in the income statement and balance sheet. In addition, this method is applied to calculate the profit margin of each unit of product and to decide the selling price of the product. Advanced technology such as an ERP system is a comprehensive solution to help with the absorption costing method.