Manufacturing methods are of many types and each method has its pros and cons. Batch production is one such type which is also called as batch manufacturing. It is a popular and old-school method. Plus, it is one of the production processes that give manufacturers the liberty to work on unique configurations effortlessly.

In the batch manufacturing process, the products are made in batches and it undergoes a series of steps to complete finished products. Further, it is used for smaller product runs where similar products or goods with similar customisations are produced in batches. Usually, the products will go through the first step in batches and it is put on wait for the next stage.

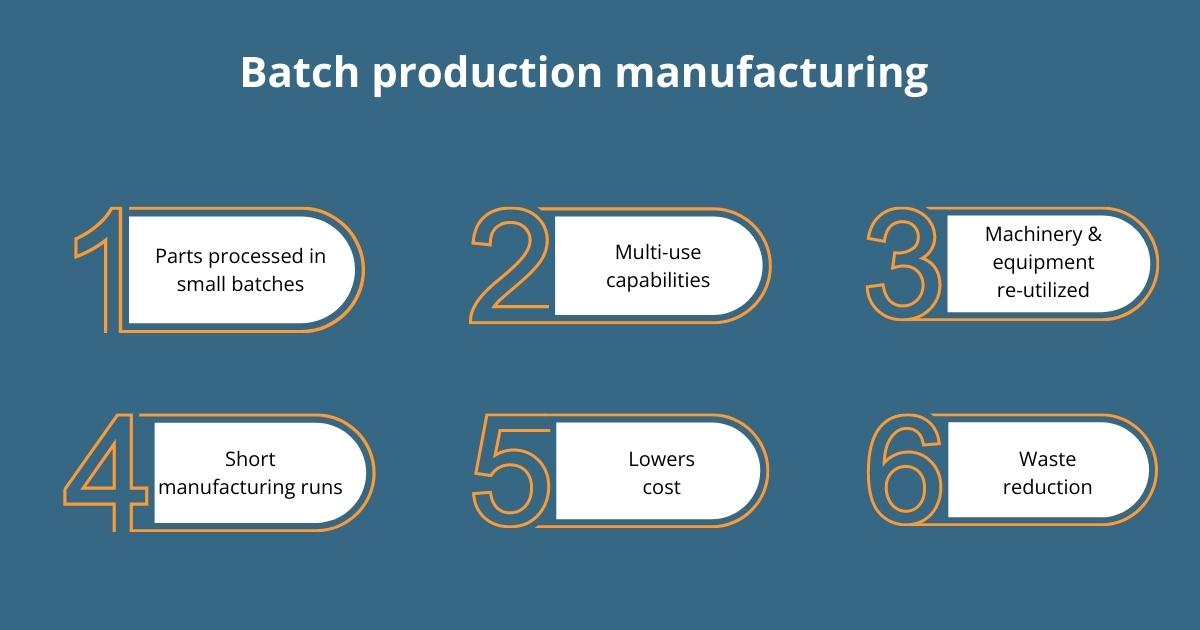

Implementing batch production techniques for the production of goods provides many benefits. First, it helps manufacturers to manage and control any number of items that occur during the manufacturing process. Second, during the production process, it is possible to make changes. Thirdly, it helps with quality control in different stages of the production process and reduces waste.

Batch production is usually used for industries such as software chip manufacturing, pharmaceuticals, and food and beverage manufacturing.

What is Batch Production in manufacturing?

Batch production is the process of manufacturing products in batches where the assembly is done in a series of different stages. It is a boon for the manufacturing industry in many ways. Let’s discuss how it helps the manufacturers —

- It has the ability to produce goods in small quantities.

- It makes the entire manufacturing process more agile and efficient.

- The products used for batch production don’t have to be continually made, it has the ability to scale up the production of any product that had been previously done by manual labour.

- Generalist equipment is utilised by the business to perform various manufacturing functions.

Examples of Batch manufacturing for different industries

Batch production is suitable for numerous industries such as it ranges from pharmaceuticals to clothing, chemicals and food-based products. It’s a rule of thumb, if a factory can manufacture multiple products in the same machinery, batch manufacturing is adopted.

For example, a pharma company doesn’t have to produce cold and flu tablets around the year. The cold and flu tablets can be manufactured seasonally. So the machines will be free at other times, where they can be utilised to make other medicines in batches.

And one more example is bakeries, which make different goods using the same equipment(oven, baking trays and mixing bowls). And based on demand forecasts they can scale up the production of various bakery items.

How is Batch manufacturing applied to industries?

Three major elements are simplified with the batch management system – raw materials, inventory and finished goods. Let’s see how this type of production method is used in the manufacturing industry.

1. Batch numbers creation

The creation of batch numbers will vary from business to business. Unique numbers for batches of goods are given to provide end-to-end transparency in the production line.

2. Integrate with the right batch-tracking technology

Automating batch production with technology will yield more results. There will be more visibility of the products in each stage. This will help in avoiding errors and risks.

3. From raw materials to production to sales

Automation and visibility help in knowing the exact numbers in the inventory. This will help the production to commence at the time without causing any delay. If you are unsure about the stocks available in the inventory, it is difficult to continue with the production process.

4. Production scheduling

It is vital to understand sales forecasts. It will give insights regarding the right time to manufacture the goods. And the manufacturing software can be used to automate the scheduling process. The software will also give details regarding the demand and help in responding to priorities.

Also Read : What are the types of Manufacturing Processes?

Advantages of Batch production

Batch production is best suited for producing goods in smaller amounts. Especially, the goods that need customizations can avail of this method. Let’s discuss some advantages of batch production–

1. Multi-purpose capabilities

It has the capability to manufacture variants of items in the same assembly line. It has the ability to equip more production processes, so the equipment is never under-utilized. In this process, the focus can be laid on multiple goods, so businesses will be more agile in responding to the demand and supply.

2. Minimises Cost

With the batch manufacturing method, the cost of the manufacturing process can be lowered. As far as batch production is concerned, more products are manufactured on the same production line. Here the manufacturing costs are distributed among the goods. And the machinery also won’t continually run which will lower the costs. And the machine can be scheduled for maintenance which will reduce downtime.

3. Reduce Wastage

Manufacturing the exact number of goods will eventually minimise resource waste.

4. Quality Assurance

In the batch production process, the product quality can be checked and tested at every stage. So if any issue occurs in between the process can be rectified. This will avoid the risk of producing a batch 0f defective goods.

5. Items manufactured in small quantities

In this process, goods can be produced in smaller quantities but various goods can be manufactured. And the goods are manufactured depending on the request.

Disadvantages of Batch production

One major disadvantage of batch production is that it is not suitable for all types of industries. Some of the disadvantages are enumerated below —

1. Automating issues

Automating the batch manufacturing process is challenging due to the requirements of variables. And also the process method and the equipment considers varied attributes for each commodity.

2. Costlier than mass production

Batch manufacturing has more stages in the manufacturing process. In addition, it has many quality control checks, tests and stages, which makes it expensive. And the initial set-up of technology is expensive as it has to be designed to cater for the specific requirements of functions.

3. Employee downtime is probable

Batch manufacturing involves multiple stages of production and numerous quality control checks. So there will be a pause after each stage which increases the employee downtime. For example, in the food industry‘s manufacturing process, after each stage, the equipment has to be cleaned.

4. Longer production time

In the batch production method, there are more stages and each step has to be completed and then only proceeded to the next phase. So the manufacturing process will take a longer duration to complete. For example, if any modifications are to be done for the functions of the equipment to proceed next step, it will take time.

Also Read : 10 Manufacturing ERP Modules You should look for in an ERP System

What is a Batch tracking system?

Integration with batch tracking software will increase the efficiency of batch manufacturing. Listed below are some of the reasons —

- Automation enables the traceability of functions which helps in being time-efficient. Especially, tracking the raw materials from procurement till the sales of the finished product.

- Enhanced visibility of inventory stocks will help in prioritizing to use of the oldest stocks first which helps in reducing wastage. This is vital for largely perishable goods.

- Compliance is a major requirement for food and pharmaceutical products. So if there is a health or safety-related recall, the right technology and software in place help the company from reputational damage.

What are Batch Manufacturing records?

Batch manufacturing records document all the functions of the entire manufacturing process. It is normally a written document. In this step-by-step process of batch manufacturing and the whole manufacturing process is recorded. A batch manufacturing record should have the following information —

1. Batch record – BMR’s first page has the following details – batch number, batch size, composition, master formula record (weight of the batch, shelf life, storage conditions, manufacturing date, expiry date, manufacturing license number, starting date and completion date)

2. General instructions for production – Health and safety instructions that the manufacturing chemist and operators have to follow during the production process. The instructions are regarding the equipment and materials used for the production process.

3. Equipment cleaning record – A list of equipment used for the manufacturing process is created. It includes details of the previous product, batch and date of cleaning. And equipment cleaning should be based on quality assurance.

4. Bill of materials – In this, the raw materials are listed along with the quantity and their own AR numbers. Quality assurance has to verify the weight of these materials. For example, in the pharmaceutical business, some of the tablets manufactured might be coated, so the coating materials must be specified.

5. Estimated cost of each manufacturing step – The cost of each manufacturing stage is specified in the MRF. And this is documented after computing and multiplying the cost of any equipment utilised by the labour hours required.

Conclusion

Finally, batch production is considered to be a highly efficient manufacturing method for the production of goods in specified quantities. It can help with cost savings, quality control, and flexibility in meeting customer expectations. Technology such as an ERP system is a comprehensive solution to efficiently manage batch production.