Best ERP for Manufacturing Industry in India

ERP for manufacturing industry empowers your business with unprecedented visibility and reduced complexities to help you stay ahead of the curve

ERP for manufacturing industry empowers your business with unprecedented visibility and reduced complexities to help you stay ahead of the curve

India’s manufacturing sector is considered the bedrock of the country’s economic growth. According to a report by Statista, it is estimated to be $232.3 Billion in size as of 2024. It is projected to grow with a CAGR of 3.46% between 2024 and 2029.

The manufacturing sector is one of the most contributing sectors to India’s GDP, with a record 16% share during the pre-pandemic era. There are several factors contributing to the growth of the manufacturing sector in India. Recently, the Govt of India has incentivized Rs. 18,000 Crore to boost local manufacturing in the country.

Sage X3 is a highly scalable and customizable Manufacturing ERP that can adapt to your industry-specific requirements. It offers an extensive set of features such as deep analytical insights, production planning, demand forecasting, BOM management, work order management, and vendor management, among others.

Manufacturing companies with multiple locations often face the challenge of integrating their operations. It is due to a need for more standardization, complex process management, and resource fragmentation across areas. To overcome this challenge, companies must work to streamline and coordinate their operations across all locations.

The need for more critical information has a significant challenge for manufacturing companies. With ever-evolving customer preferences, regulatory changes, and technological advancements, manufacturers must have access to the correct information quickly to stay competitive. Companies need the right data to stay caught up, leading to decreased profits.

Manufacturing companies face the challenge of ensuring optimum resource utilization to maximize productivity and profitability. They need to plan and manage their resources to achieve their objectives proactively. It involves analyzing their current resources and deploying them most efficiently and cost-effectively. Some manufacturers’ common resource utilization challenges are an inadequate investment in technology, a lack of skilled employees, and inadequate planning and forecasting.

Reduced employee productivity leads to low revenue and poor customer service. Poor customer service leads to customer dissatisfaction and reduced customer loyalty, which can affect a business’s success. Factors affecting employee productivity in manufacturing companies include job stress, lack of motivation and recognition, too much work, or inefficient work processes. Companies must address these issues to ensure their employees remain productive and motivated.

Manufacturing companies need Inventory Management Software to effectively handle their inventory, reduce inventory costs, and gain efficiency. Inventory control ensures that manufacturing companies have suitable raw materials and components to meet customer demand. Inventory control can lead to decreased production, higher costs due to wastage, and delayed deliveries. Appropriate inventory control plays an essential role in a manufacturing company’s success. It keeps the company stocked with enough parts to meet customer orders, allowing it to remain competitive.

Manufacturing ERP streamlines various organizational operations and promotes the free flow of data across the organization. Here’s how it works:

ERP acts as the central repository of truth that empowers decision-makers with critical business insights for strategic planning and performance analysis. With the help of the right tools and accurate data in hand, the business gains a competitive advantage in the evolving market landscape.

ERP software for manufacturers builds a complete database of all your vendors and tracks their performance. It helps you flag over-charging vendors and avail the lowest deals ever. It frees up your staff from the manual task of cost comparison so that they can focus on more productive operations.

The consequences of non-compliance can be severe. Your company can face fines, penalties, and lawsuits, and it can impact the company’s reputation in the eyes of the general public. An ERP for manufacturers helps you stay compliant with complex & ever-changing regulations and mitigate risks.

The AP Automation module streamlines vendor payments so that you can avail of early payment discount offers and maintain good terms with the vendors. Similarly, AR Automation speeds up the collections from your customers and enhances your cash flow.

These days, it’s common for large manufacturing companies to have different units across different locations. Overseeing operations across each of these units can be a tedious task. ERP for manufacturing industry equips decision-makers with real-time data syncing between different units and a holistic view of organizational operations for better planning.

If you’re aspiring to take your business to the global level and capture new geographies, you’ll need a handy tool that supports global transactions. Manufacturing software automates currency conversion operations, provides a localized experience to your buyers, and reduces human work.

Sage X3 ERP for manufacturers helps manufacturing companies streamline their processes, reduce overheads, and improve overall productivity. With the help of automated processes, companies can eliminate manual errors, improve accuracy, and reduce time-consuming tasks.

Sage X3 provides a single source of truth for all manufacturing data, making it easier to find, track, and analyze the data. Its intelligent Business Intelligence tools allow companies to identify areas of improvement, stay compliant, and make data-driven decisions.

The ERP software for manufacturers can provide customers with accurate information about their orders, deliveries, pricing, and inventory levels. It helps to improve customer relationships and increase customer satisfaction.

Sage X3 ERP for the manufacturing industry provides real-time visibility into operational performance and helps to identify potential issues before they become problems. The best ERP application for manufacturing industry improves the overall performance of the manufacturing process.

In today’s competitive environment, businesses have to consistently produce safe & high-quality goods to maximize customer satisfaction, meet industry standards, and reduce non-compliance penalties. Best ERP for manufacturing industry enables businesses to track quality at every level, maintain quality data, and compare it with industry standards.

Integrating the ERP for manufacturing industry into the manufacturing process leads to lower lead times. Businesses can reduce downtimes, and meet consumer demands on time. Manufacturing software provides powerful tools to make detailed production plans, and efficiently allocate production resources.

ERP software for manufacturers eliminates production bottlenecks, minimizes waste, ensures optimum use of resources, and reduces supply chain gaps, all of which collectively help keep the manufacturing (overhead) cost lower. Ultimately, you benefit from increased profit margin, competitive pricing, and expansion of your consumer base.

One of the key benefits of ERP is predictive maintenance, a term used for condition-based machine maintenance. Your ERP records complete machine logs (including failure data), asses machine conditions in the real-time, and predicts potential breakdowns to reduce potential business disruptions.

Unlock Your Business Potential with Sage X3

Empower your team and elevate your results with ERP Software

Bill of Materials (BOM) planning is a critical feature that allows tracking and managing the raw materials, components, and sub-assemblies used in the production process.

Sage ERP India allows you to create and manage a list of all the items used in the manufacturing process, including their quantity, cost, and supplier details. This information is essential for ensuring that suitable materials are always in stock and that you have an accurate picture of the costs associated with the production.

The Inventory management feature of Sage X3 ERP software helps manufacturers accurately track materials and products as they move through the supply chain. It includes tracking the lot or serial numbers, barcodes, expiration dates, and locations of raw materials, components, and finished goods.

The Manufacturing ERP software allow manufacturers to accurately monitor inventory levels as they move through the production process. It ensures that materials are well-stocked and utilized. Moreover, it helps manufacturers control costs, improve efficiency, and reduce errors associated with manual inventory tracking.

ERP for Supply Chain Management is essential software for any business looking to streamline its supply chain operations and gain better control over the entire process from order tracking, forecasting, and inventory management to delivery optimization.

The business management software provides the ability to generate accurate reports to understand production planning, inventory levels, and delivery times. It also helps to ensure that goods are purchased from suitable suppliers and that products arrive on time and in the correct quantities.

Production reporting & analytics feature enable manufacturers to measure performance in production efficiency, resource utilization, delivery accuracy, and customer satisfaction. With these key feature, manufacturers can identify areas of opportunity and quickly take corrective action to ensure the timely delivery of products.

Besides, using the reporting and analytics features in the production ERP can help businesses determine various ways to make improvements in the manufacturing process. For example, furniture manufacturers use a dedicated ERP for Furniture Manufacturing to identify which raw materials might be overstocked, what products could be more efficiently manufactured, and how to minimize costs. It allows them to make more informed decisions and increase their profitability.

Production management within an ERP system helps organizations automate and streamline operations, reduce costs and improve accuracy. It is an effective method for tracking, controlling, and analyzing production data. The system offers a wide range of tools and features such as Advanced Planning & Scheduling, and Material Requirements Planning (MRP) that enable production managers to identify and address areas of vulnerability.

It includes tracking stock levels, monitoring workflows, reducing Factory Overhead, managing costs and balancing supply and demand. ERP production management systems also provide real-time visibility of production operations.

Shop floor execution systems (SFE) feature of Sage X3 delivers critical capabilities such as real-time tracking, automated job scheduling, and enhanced inventory management. Real-time tracking allows managers to monitor an entire production system in real-time, providing visibility into every step in the production process.

Let’s take a simple example of a pharma firm which uses Pharma ERP Software for various purposes such as automated job scheduling, managing resources & tasks, improving the utilization of machines and personnel. Also, it helps improve inventory management, allowing it to predict inventory needs more accurately and reduce excesses.

The Financial management software provides key insights into the company’s financial operations and allows you to identify the areas of cost reduction. It is a critical component of the manufacturing software, equipped with powerful & accurate budgeting and forecasting tools for setting highly accurate futuristic strategies for maximizing growth & profit.

The finance module reduces potential errors in your financial statements, improves your company’s cash flow, and lowers the risk of cash shortfalls. With better financial planning & reporting tools, you can make smarter & informed decisions, and maintain audit readiness.

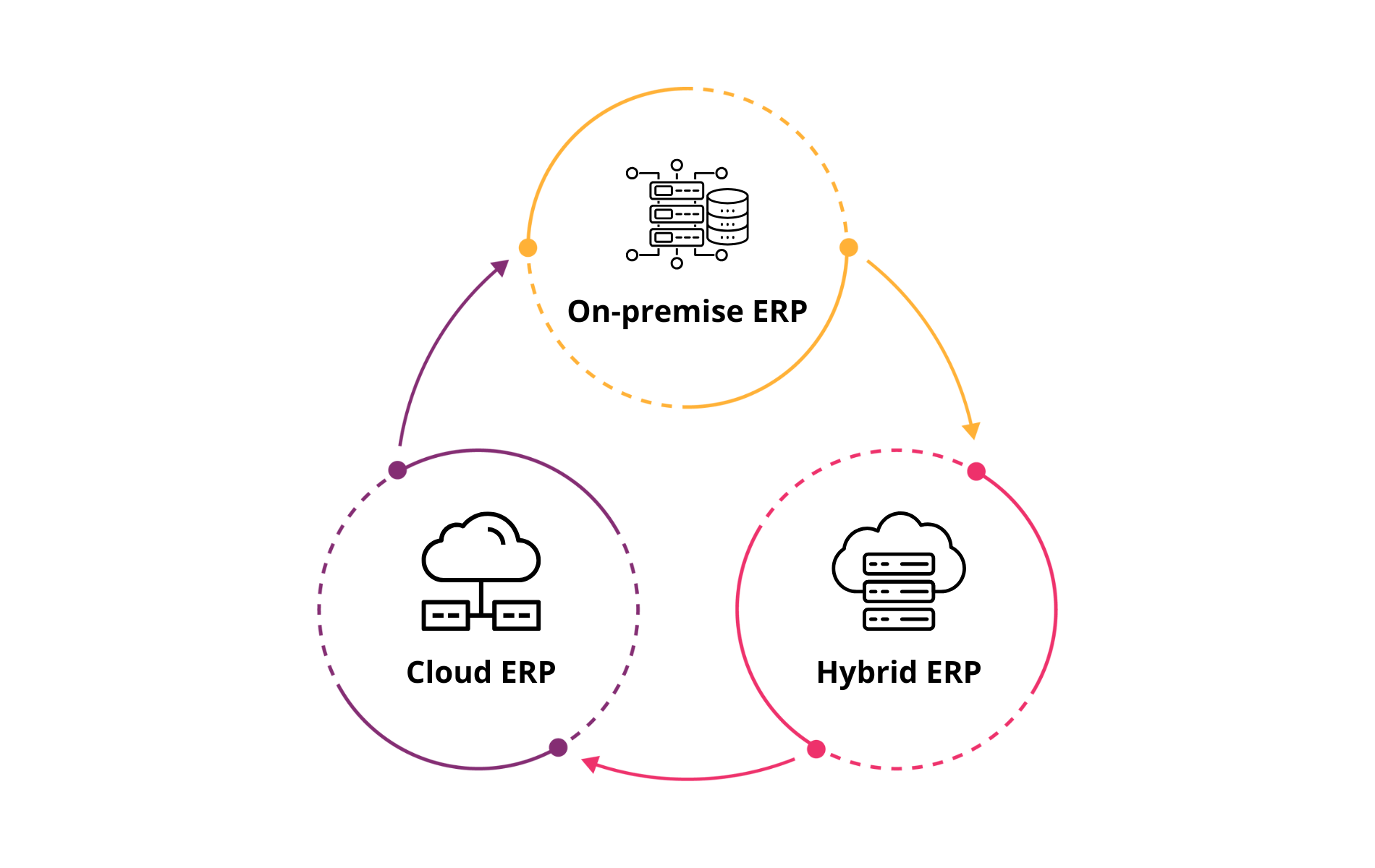

There are three types of ERP: On-premise, Cloud ERP, and Hybrid ERP. ERP software for manufacturers is evolving with time. A recent transformation in the world of manufacturing software is cloud-powered ERP eliminates the need to hire a dedicated team of IT engineers or worrying about complex technicalities associated with managing your own server.

Lower ERP cost and scalability to meet growing operational needs are other major benefits of using Cloud ERP. For example, if you’re a food manufacturer, you can go with a higher plan of the ERP for food industry to gear up for heightened demand during the festive season spikes. While the cloud-based ERP for manufacturing industry in India is a great option for small and medium-sized businesses, it comes with an important limitation. It is typically less customizable compared to an On-premise solution.

There are three types of ERP implementation. Which one would you prefer? Let’s have a look.

On-premise ERP is typically preferred by large-scale manufacturing businesses that are looking to benefit from a highly customizable system and have a dedicated team of professionals to look after the ERP implementation, regular maintenance, and upgrade.

Cloud ERP best suits small and medium-scale manufacturers with limited resources and budgets. It comes with a monthly or annual fee and frees up your business from the hassle of huge upfront costs, regular maintenance & system, and troubleshooting. Moreover, it offers robust data security practices such as role-based data protection, and encryption.

Hybrid ERP offers the best of both on-premise and cloud services. While it has its own limitations such as limited data control, it can coexist with both the systems and support seamless integration between teams. With the hybrid type, you gain limited control over some parts of your information.

The exact type of ERP implementation may depend on your company’s core requirements, budget, and industry type. Choose a type that helps you combat real-world challenges and rip the maximum benefits.

A Generic ERP is a type of ERP designed to meet the needs of multiple industries by providing common modules & capabilities. It is also known by other names such as Standard ERP.

A Manufacturing ERP, on the contrary, is a specialized solution for manufacturing companies that are looking to integrate various aspects of their business, and gain more control over the manufacturing process.

The main difference between a generic ERP and a manufacturing ERP lies in their goals. Generic ERP is typically equipped with a standard set of modules that are commonly used across all industries. This includes Inventory Management, Asset Management, Financial Management Software, and Sales Management System, among others.

In contrast, Manufacturing ERP comes with all of these modules, in addition to other manufacturer-specific modules such as Online Procurement Management System, Product Lifecycle Management, Production Scheduling, Shop Floor Control, Quality Assurance, and Materials Management, among others.

| Generic ERP | Manufacturing ERP | |

| Definition | Generic ERP is an ERP with a broader focus on multiple industries. | Manufacturing ERP is an ERP specifically designed to cater to the needs of the manufacturing industry. |

| Industrial Focus | Focuses on manufacturing, food & beverage, pharma, plastic, auto ancillary, chemical & other industries | Focuses solely on manufacturing companies |

| Scope of Real-time Data | Provides real-time data pertaining to different business operations such as production, inventory management, sales, marketing, customer support, etc. | Provides real-time data pertaining to the manufacturing activity, inventory management, and supply chain. Narrows down data to the maximum extent |

| Relevancy | Best for small and medium-sized companies | Best for large manufacturers who need a specialized feature set |

| Customization Complexity | Requires advanced customization to meet the specific needs of the manufacturing industry. | As the solution is already tailored to the needs of the manufacturers, it requires little to no customization |

| Implementation Complexity | Less complex than a Manufacturing ERP. | Often more complex than a Generic ERP. |

| Price | Relatively cost-efficient compared to the Manufacturing ERP | Relatively expensive compared to a generic solution. |

Manufacturing ERP (also known as Manufacturing Software) is a comprehensive, integrated application suite that automates and streamlines manufacturing and production processes. These systems give companies greater visibility into their production processes, allowing them to track and manage their resources better. ERP systems enable production businesses to monitor inventory levels better, monitor supplier performance and manage customer orders.

ERP software for manufacturing is commonly used in manufacturing because it helps companies manage their resources and operations more effectively. By streamlining processes and tracking production data, it can help businesses become more efficient and profitable.

Manufacturing software is an extensive business management suite that helps organizations to manage critical business processes, including financials, manufacturing, sales and customer service. It is widely used in the manufacturing sector, as it can help businesses to manage production processes more effectively and efficiently. The system can automate tasks such as inventory management, order processing and shipping, which can help companies to improve their operational efficiency.

The Best Manufacturing ERP Software helps manage your production processes, track inventory, and improve communication between departments. It can provide a single view of the entire business, which can help businesses make better decisions and improve efficiency. ERP software can be used to manage finances, inventory, operations, sales, and customer relationships.

» Manufacturing ERP is an indispensable solution for modern-day businesses. Here’s why:

It helps to streamline operations and improve efficiency.

Provides real-time information on production and inventory.

Allows manufacturers to make better decisions about what to produce and when to produce it.

Improves customer service by allowing manufacturers to quickly and easily access customer information.

Reduces costs by automating multiple business processes.

Yes, we customize ERP system as per the requirement of your company. Our team of experienced professionals understands your company’s business needs and customizes the ERP system to match your company’s specific requirements. We can customize the ERP system to integrate with existing systems and provide you with the flexibility to customize the system to suit the ever-changing needs of your business.

Enterprise resource planning implementation can be a complex process. The time it takes for an ERP system to go will depend mainly on the project’s scope and the complexity of the system being implemented. Generally, organizations can expect an ERP implementation in the manufacturing industry anywhere from two weeks to six months, depending on the size and complexity of the project.

For a small business, the time frame can be relatively short. Initially, the length of time it will take to go live can be estimated by assessing the project’s scope. As the project management software progresses for the manufacturing industry, the timeline may need to be adjusted depending on the team’s progress.

There are various advantages of ERP that leverage cloud technology. A web-based ERP in manufacturing helps streamline all business functions and departments through standard processes. It also helps manufacturing businesses meet quality compliances and give outputs faster with top manufacturing solutions. The system also provides high services to customers, partners, and more.

Material Management ERP enables organizations to have more accurate and timely control over their supply chain, from goods acquisition to delivery process. In other words, manufacturing process management software simplifies the process of ordering, tracking, and distributing materials. ERP for manufacturers also helps organizations reduce costs, streamline operations, and comply with regulations. It can track orders and deliveries, optimize inventory, provide pricing tools and improve purchasing processes.

Schedule Product Tour

"*" indicates required fields

Fill in the details below and we would be glad to help you.